- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

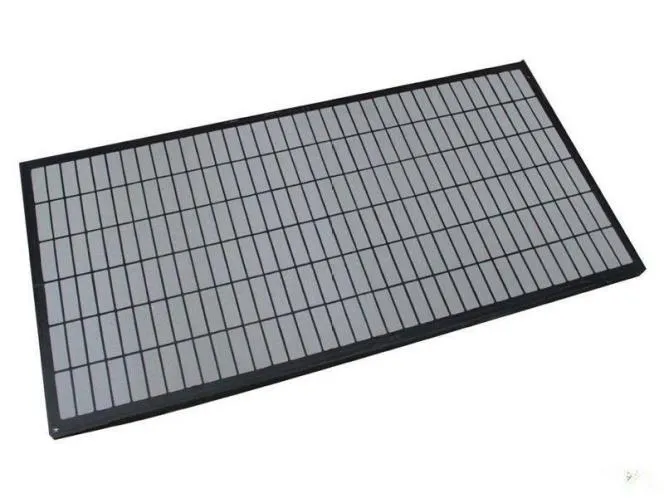

Galvanized Steel Grating for Durable and Versatile Industrial Applications

Galvanised Metal Grating A Comprehensive Overview

Galvanised metal grating is a popular choice in various industries for its strength, durability, and resistance to corrosion. This type of grating is typically made from carbon steel that undergoes a galvanisation process, which involves coating the metal with a layer of zinc. The resulting product not only boasts enhanced protection against rust and environmental degradation but also maintains the structural integrity and functionality that many applications require.

The galvanisation process is crucial in extending the lifespan of metal grating. It involves cleaning the steel to remove rust, oil, and other contaminants, followed by immersion in molten zinc. This creates a metallurgically bonded coating that adheres tightly to the surface of the steel. The zinc layer acts as a sacrificial anode, which means that when exposed to the elements, zinc will corrode before the underlying steel, thus preventing rust even in harsh environments. This characteristic makes galvanised metal grating an ideal choice for outdoor installations and in industrial settings where moisture and chemicals may be present.

One of the most significant advantages of using galvanised metal grating is its structural strength. Steel grating is known for its ability to bear heavy loads, making it suitable for walkways, platforms, and support structures in industrial plants and warehouses. The open design of metal grating also allows for excellent drainage, ensuring that liquids flow through easily without pooling, thereby reducing slip hazards and maintaining safety.

galvanised metal grating

In addition to its practical benefits, galvanised metal grating is incredibly versatile. It can be manufactured in various sizes, shapes, and mesh configurations to meet specific application needs. Common types include welded, pressed, and swaged grating, each offering unique benefits depending on the load requirements and installation environment. This versatility makes it suitable for use in diverse industries, including construction, manufacturing, oil and gas, and food processing.

Moreover, galvanised metal grating requires minimal maintenance compared to other materials. The protective zinc coating significantly reduces the need for frequent repairs or replacements, which can be both time-consuming and costly. Facility managers and industrial operators appreciate the long-lasting nature of galvanised grate, as it allows them to focus resources elsewhere while ensuring their safety and operational efficiency.

The aesthetic appeal of galvanised metal grating should not be overlooked either. Its sleek and modern appearance makes it an attractive option for not only functional applications but also architectural designs. Many contemporary buildings utilize galvanised grating for staircases, decks, and even decorative facades, blending functionality with design.

In conclusion, galvanised metal grating is an exceptional choice for both industrial and architectural applications. Its combination of durability, corrosion resistance, strength, and versatility makes it an attractive option for project managers, engineers, and designers alike. With its low maintenance requirements and long lifespan, galvanised metal grating can provide significant cost savings over time, making it a wise investment for anyone looking to enhance safety and performance in their facility. Whether you need it for walkways, platforms, or as part of a creative structural design, galvanised metal grating stands out as one of the most reliable solutions in the market today.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025