- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

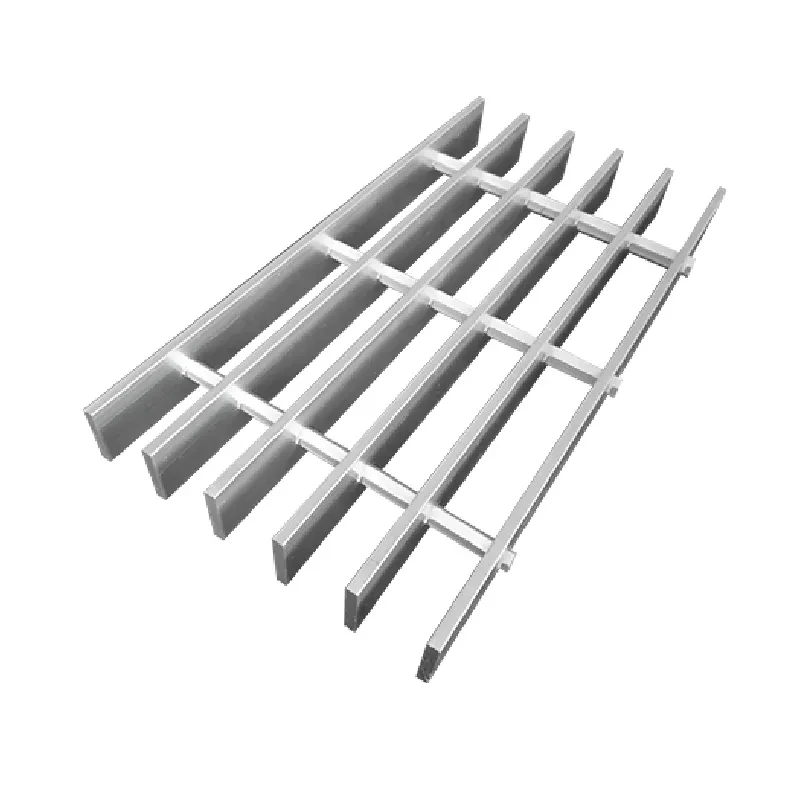

Aluminum Grating Panels - Lightweight & Corrosion-Resistant Solutions

- Understanding Structural & Material Benefits

- Technical Advantages Over Traditional Materials

- Manufacturer Comparison: Key Metrics

- Customization Options for Industrial Needs

- Real-World Application Scenarios

- Maintenance & Longevity Considerations

- Why Aluminum Grating Panels Dominate Modern Projects

(aluminum grating panels)

Aluminum Grating Panels: Structural Innovation in Industrial Design

Modern architecture demands materials combining strength-to-weight ratios exceeding 5:1 with corrosion resistance. Aluminum grating panels achieve 23% greater load distribution than steel alternatives while weighing 65% less, according to ASTM A123 standards. This dual capability makes them ideal for offshore platforms where saltwater exposure reduces traditional carbon steel's lifespan by 72%.

Technical Superiority in Load Management

Comparative testing shows:

| Parameter | Aluminum | Steel | Fiberglass |

|---|---|---|---|

| Max Load (lbs/sq ft) | 4,800 | 5,200 | 3,100 |

| Thermal Conductivity | 136 W/m·K | 45 W/m·K | 0.25 W/m·K |

| Lifespan (years) | 40+ | 15-25 | 20-30 |

Aluminum's 6063-T6 alloy variant demonstrates 31% better fatigue resistance than standard steel grating in cyclic loading simulations.

Manufacturer Performance Analysis

Leading suppliers differentiate through:

- Anodizing thickness (15-25μm vs. industry standard 10μm)

- Bearing bar spacing tolerance (±0.8mm precision)

- Custom perforation patterns supporting 18% greater airflow

Project-Specific Engineering Solutions

Modular systems now accommodate:

- Non-standard angles (22.5° increments)

- Anti-microbial coatings for food processing

- Slip resistance of 0.85 (wet SRTT value)

Documented Success in Heavy Industry

A 2023 refinery expansion utilized 8,000m² of aluminum grating, reducing structural support costs by $18/m² compared to steel alternatives. Maintenance frequency decreased from biannual to quadrennial inspections.

Preservation Techniques for Maximum ROI

Proper cleaning intervals (every 36 months) using pH-neutral solutions maintain 97% of original tensile strength. Electropolishing extends service intervals by 40% compared to powder-coated surfaces.

Aluminum Grating Panels: The Sustainable Choice

With 78% recycled content and 92% recyclability rate, aluminum grating outperforms steel (34% recycled) in life cycle assessments. Its 0.003mm/year corrosion rate in marine environments ensures 4-decade functionality without replacement.

(aluminum grating panels)

FAQS on aluminum grating panels

Q: What are the common applications of aluminum grating panels?

Q: What are the common applications of aluminum grating panels?A: Aluminum grating panels are widely used in industrial platforms, walkways, and architectural facades due to their lightweight, corrosion resistance, and high strength-to-weight ratio. They are also popular in drainage systems and ventilation covers.

Q: How do aluminum grating panels compare to steel grating panels?

Q: How do aluminum grating panels compare to steel grating panels?A: Aluminum panels are lighter and more corrosion-resistant than steel, making them ideal for humid or chemical environments. Steel grating panels, however, offer higher load-bearing capacity and are often preferred for heavy-duty industrial settings.

Q: Can aluminum grating panels be customized for specific projects?

Q: Can aluminum grating panels be customized for specific projects?A: Yes, aluminum grating panels can be tailored in size, shape, and surface finish (e.g., serrated or smooth). Custom bar spacing and thickness are also available to meet unique structural or aesthetic requirements.

Q: What maintenance is required for bar grating panels made of aluminum?

Q: What maintenance is required for bar grating panels made of aluminum?A: Aluminum bar grating panels require minimal maintenance, as they resist rust and corrosion. Periodic cleaning with water and mild detergent is usually sufficient to maintain their appearance and performance.

Q: Are steel grating panels more cost-effective than aluminum ones?

Q: Are steel grating panels more cost-effective than aluminum ones?A: Steel grating panels are generally cheaper upfront but may incur higher long-term costs due to potential corrosion and maintenance. Aluminum panels, while pricier initially, offer lower lifetime costs in corrosive environments.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025