- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 01, 2025 06:13

Back to list

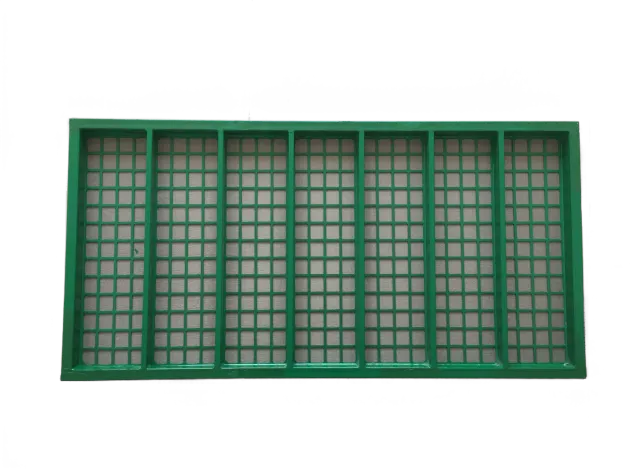

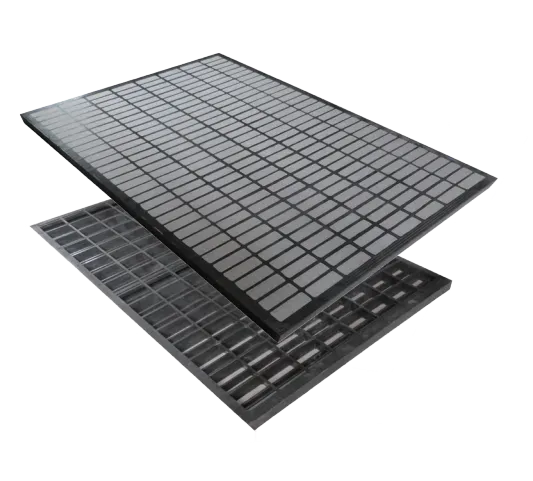

Steel Grating

Industrial metal floor grates have revolutionized the manner in which industrial spaces manage drainage, ventilation, and even safety. These often-overlooked components of industrial design are essential for providing a safe, efficient, and durable infrastructure. Drawing from years of experience in the field, it's clear that understanding the nuances of floor grates is crucial for industry professionals seeking to optimize their facilities.

Equally vital is regular maintenance, a facet often underappreciated yet critical for the long-term efficacy of floor grates. This involves periodic inspections for signs of wear and tear, such as rust or surface deformation, and ensuring that the grates remain unobstructed to perform their drainage roles effectively. Businesses can build further trustworthiness by adopting proactive maintenance schedules, an aspect that can save significant costs in potential downtime or damage to both the facility and industrial equipment. Moreover, the customization potential of metal floor grates is significant. As industries continue to evolve, so too do the requirements placed on infrastructural elements. Custom solutions may include specific mesh sizes for accommodating particular fluid viscosities or tailored load ratings to support specialized machinery. These solutions necessitate collaboration with experienced manufacturers who understand the intricate demands of your facility and are capable of producing bespoke grates that meet those specifications. The integration of technological advancements should not be overlooked. In the field of industrial grates, innovations such as anti-bacterial coatings or intelligent materials that can signal when maintenance is due are at the forefront of ensuring maximum safety and efficiency. Industry leaders maintaining their competitive edge do so by embracing these advancements and embedding them into everyday use, thereby enhancing both product longevity and workplace safety. Conclusively, the role of industrial metal floor grates in modern facilities extends beyond mere utility. They are integral to the overall operational efficiency and safety standards that define your business. As someone deeply entrenched in this sector, I recognize the significant impact the correct choice and handling of these grates have on long-term success. Prioritizing expertise, authority, and steadfast trust in all processes related to metal floor grates serves not just in safeguarding infrastructure but in enhancing productivity and ensuring a safe working environment.

Equally vital is regular maintenance, a facet often underappreciated yet critical for the long-term efficacy of floor grates. This involves periodic inspections for signs of wear and tear, such as rust or surface deformation, and ensuring that the grates remain unobstructed to perform their drainage roles effectively. Businesses can build further trustworthiness by adopting proactive maintenance schedules, an aspect that can save significant costs in potential downtime or damage to both the facility and industrial equipment. Moreover, the customization potential of metal floor grates is significant. As industries continue to evolve, so too do the requirements placed on infrastructural elements. Custom solutions may include specific mesh sizes for accommodating particular fluid viscosities or tailored load ratings to support specialized machinery. These solutions necessitate collaboration with experienced manufacturers who understand the intricate demands of your facility and are capable of producing bespoke grates that meet those specifications. The integration of technological advancements should not be overlooked. In the field of industrial grates, innovations such as anti-bacterial coatings or intelligent materials that can signal when maintenance is due are at the forefront of ensuring maximum safety and efficiency. Industry leaders maintaining their competitive edge do so by embracing these advancements and embedding them into everyday use, thereby enhancing both product longevity and workplace safety. Conclusively, the role of industrial metal floor grates in modern facilities extends beyond mere utility. They are integral to the overall operational efficiency and safety standards that define your business. As someone deeply entrenched in this sector, I recognize the significant impact the correct choice and handling of these grates have on long-term success. Prioritizing expertise, authority, and steadfast trust in all processes related to metal floor grates serves not just in safeguarding infrastructure but in enhancing productivity and ensuring a safe working environment.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025