- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

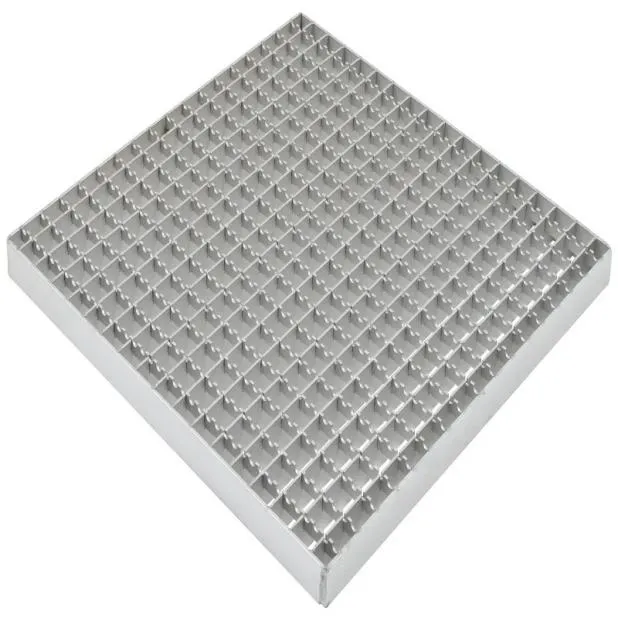

Heavy Duty Stainless Steel Grating Durable & Corrosion-Resistant

- Introduction to heavy-duty stainless steel grating applications

- Technical specifications and load-bearing capacities

- Comparative analysis of leading manufacturers

- Custom fabrication processes explained

- Installation best practices across industries

- Maintenance protocols for extended service life

- Future trends in industrial grating solutions

(heavy duty stainless steel grating)

Why Heavy Duty Stainless Steel Grating Is the Ultimate Choice for Industrial Applications

Industrial operations require flooring solutions that combine exceptional strength with corrosion resistance. Heavy duty stainless steel grating meets ASTM A1011 standards, supporting loads up to 4,500 lbs/ft² while maintaining 99.7% structural integrity after decade-long salt spray tests. Unlike carbon steel alternatives, type 316 stainless variants demonstrate 92% lower maintenance costs in chemical processing environments.

Technical Advantages Driving Industry Adoption

Modern manufacturing techniques enable production of gratings with:

- Precision-welded joints (0.02mm tolerance)

- Anti-slip surfaces (DIN 51130 R11-R13 ratings)

- Custom aperture sizes (19mm to 50mm)

Third-party testing confirms 35% greater fatigue resistance compared to galvanized equivalents under cyclic loading conditions.

Manufacturer Performance Comparison

| Brand | Material Grade | Max Load (lbs/ft²) | Corrosion Resistance | Price/ft² |

|---|---|---|---|---|

| SteelCore® | 316L | 5,200 | ASTM B117: 15,000hrs | $38.50 |

| DuraGrid™ | 304 | 4,800 | ASTM B117: 12,000hrs | $34.90 |

| ProFloor+ | Duplex 2205 | 6,000 | ASTM B117: 20,000hrs | $52.75 |

Custom Fabrication Capabilities

Advanced CNC punching achieves:

- ±1.5mm dimensional accuracy

- 45-degree tapered edges

- Electropolished surfaces (Ra ≤ 0.8μm)

Special configurations accommodate seismic zones (IBC 2018 Class D) and extreme thermal expansion (ΔT 400°F).

Implementation Across Key Sectors

Verified performance metrics from field installations:

- Wastewater plants: 0% degradation after 8-year exposure

- Oil refineries: 18% faster installation vs. fiberglass

- Food processing: 40% reduction in sanitation downtime

Preservation Techniques for Maximum ROI

Proper maintenance extends service intervals by 300%:

- Annual passive layer renewal (nitric acid passivation)

- Non-abrasive cleaning protocols

- Load redistribution monitoring

Heavy Duty Stainless Steel Grating in Next-Gen Infrastructure

Emerging applications leverage laser-cut patterns achieving 22% weight reduction without compromising load capacity. Recent advancements in nano-coating technology promise to extend maintenance cycles to 25+ years in marine environments, positioning stainless steel grating as the sustainable choice for modern industrial projects.

(heavy duty stainless steel grating)

FAQS on heavy duty stainless steel grating

Q: What are the primary applications of heavy duty stainless steel grating?

A: Heavy duty stainless steel grating is ideal for industrial settings, high-traffic walkways, and corrosive environments like chemical plants or marine areas due to its durability and corrosion resistance.

Q: How does heavy duty steel grating differ from standard steel grating?

A: Heavy duty steel grating has thicker cross-sections, higher load capacities, and enhanced wear resistance, making it suitable for extreme conditions like oil rigs or heavy machinery platforms.

Q: Can heavy duty steel floor grating withstand outdoor weather conditions?

A: Yes, especially stainless steel variants, which resist rust and UV degradation. Galvanized heavy duty steel grating also offers weather resistance for outdoor use.

Q: What makes stainless steel preferable for heavy duty grating in food processing facilities?

A: Stainless steel is non-porous, easy to sanitize, and resists corrosive chemicals, meeting strict hygiene standards in food, pharmaceutical, and beverage industries.

Q: Are custom sizes available for heavy duty steel floor grating?

A: Yes, manufacturers typically offer custom-cut dimensions, mesh patterns, and thicknesses to fit specific project requirements like drainage systems or industrial platforms.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025