- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

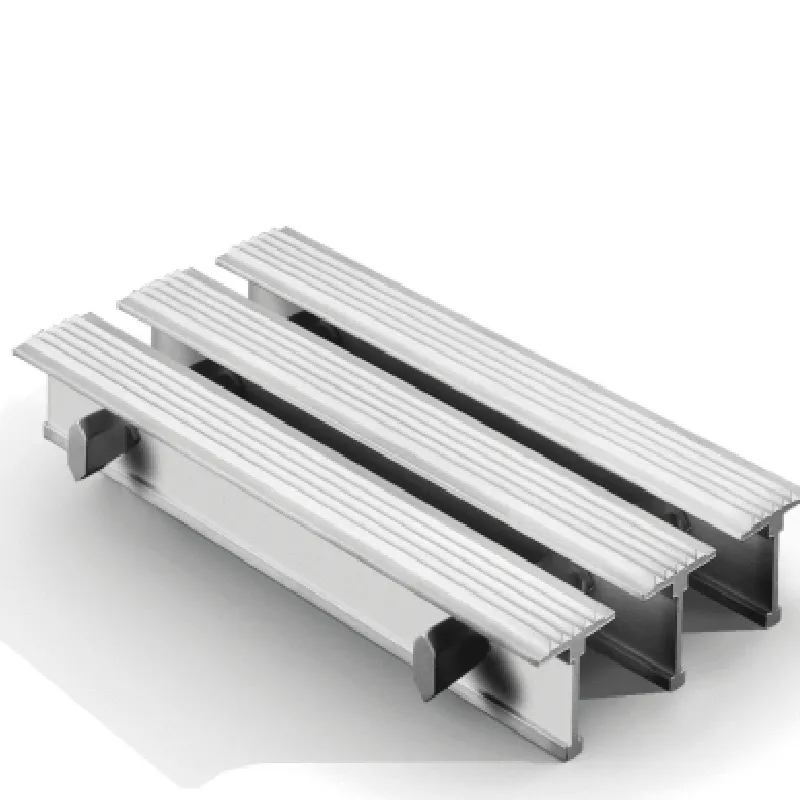

galvanized steel grating platform

Galvanized Steel Grating Platforms A Comprehensive Overview

Galvanized steel grating platforms have become an integral part of modern industrial and commercial environments. Known for their durability, strength, and versatility, these platforms are manufactured through a process that coats steel with a layer of zinc to protect against corrosion. This article explores the features, applications, and advantages of galvanized steel grating platforms.

What is Galvanized Steel Grating?

Galvanized steel grating is constructed from steel bars welded together to form a grid-like structure. The galvanization process involves dipping the steel in molten zinc, resulting in a robust protective layer that can withstand harsh environmental conditions. This makes galvanized steel grating highly resistant to rust and corrosion, which is particularly beneficial in settings exposed to moisture, chemicals, or extreme weather conditions.

Key Features

1. High Load-Bearing Capacity Galvanized steel grating platforms are designed to support heavy loads, making them ideal for industrial applications such as walkways, access areas, and platform floors. Their structural integrity ensures safety even under significant weight.

2. Slip Resistant The surface of galvanized steel grating often features a serrated or textured finish, providing excellent traction. This is crucial in preventing slips and falls in environments where oils or other slip-inducing materials may be present.

3. Easy Installation and Maintenance These platforms are relatively easy to install due to their lightweight nature and modular design. Standardized sizes allow for easy customization to fit varying spaces. Additionally, maintenance is straightforward; regular cleaning can keep them in good condition without the need for extensive repairs.

galvanized steel grating platform

4. Cost-Effective Solution While the initial investment for galvanized steel grating may be higher than some alternatives, the long lifespan and minimal maintenance requirements make it a cost-effective choice over time.

Applications of Galvanized Steel Grating Platforms

Galvanized steel grating platforms find applications across various industries, including

- Manufacturing Used for walkways, platforms, and working surfaces in factories and assembly lines. - Construction Commonly employed as scaffolding platforms and temporary structures due to their strength and stability. - Aerospace and Aviation Utilized in hangars and maintenance areas where weight capacity and safety are paramount. - Wastewater Treatment Ideal for use in plant walkways and covers due to their resistance to corrosive materials. - Marine Environments Essential in shipbuilding and dock construction, where exposure to saltwater requires materials that can withstand corrosion.

Advantages

The advantages of galvanized steel grating platforms extend beyond their physical properties. The eco-friendly aspect of galvanization also contributes to their appeal, as zinc can be recycled. Moreover, their longevity means fewer replacements and less waste in landfills.

Conclusion

In summary, galvanized steel grating platforms represent a versatile, durable, and cost-effective solution for a multitude of industrial applications. Their superior resistance to corrosion and slip hazards ensures safety and reliability in demanding environments. As industries continue to prioritize safety and efficiency, galvanized steel grating platforms will remain a go-to choice for engineers, architects, and contractors alike.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025