- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sau . 20, 2025 16:33

Back to list

Steel Grating

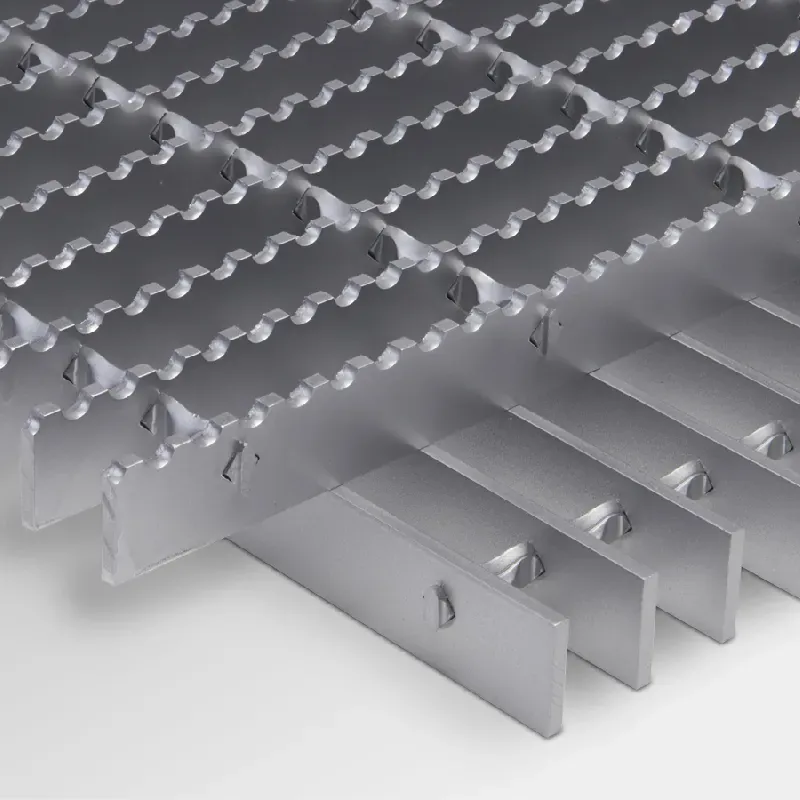

Swage locked grating is not just a product; it's a multi-purpose solution for numerous industrial and commercial needs. As a dynamic component, it brings together innovation, strength, and safety into one essential element. Swage locked grating is engineered for performance and durability, making it a preferred choice across various sectors, including construction, mining, manufacturing, and public infrastructure.

Moreover, swage locked grating is lauded for its ease of installation and maintenance. Its lightweight nature facilitates handling and speeds up the installation process, saving time and labor costs. Maintenance requirements are minimal, primarily requiring periodic inspections to ensure the grating remains free from obstruction and damage. When necessary, sections can be replaced individually, eliminating the need for a complete overhaul, further enhancing its cost-effectiveness. Choosing the right type of swage locked grating begins with a thorough assessment of its intended environment and use-case. Experts recommend considering factors such as exposure to corrosive elements, expected load bearing, and the need for customization. For instance, high traffic areas might necessitate thicker cross bars for added strength, whereas environments with aesthetic considerations might prefer aluminum for its sleek finish. A trust-building aspect of swage locked grating use is the assurance it provides through compliance with industrial standards. Generally, these gratings meet or exceed regulatory requirements, providing further assurance to managers and stakeholders responsible for safety and quality assurance in industrial operations. In conclusion, swage locked grating is a synthesis of engineering excellence and functional design. For industries looking for reliable, versatile, and maintenance-friendly solutions, it stands as an authoritative choice highly recommended by experts in material engineering and industrial safety. Ultimately, its adoption can lead to significant advantages in terms of durability, safety, and aesthetic appeal, representing a vital component in the success and efficiency of diverse projects.

Moreover, swage locked grating is lauded for its ease of installation and maintenance. Its lightweight nature facilitates handling and speeds up the installation process, saving time and labor costs. Maintenance requirements are minimal, primarily requiring periodic inspections to ensure the grating remains free from obstruction and damage. When necessary, sections can be replaced individually, eliminating the need for a complete overhaul, further enhancing its cost-effectiveness. Choosing the right type of swage locked grating begins with a thorough assessment of its intended environment and use-case. Experts recommend considering factors such as exposure to corrosive elements, expected load bearing, and the need for customization. For instance, high traffic areas might necessitate thicker cross bars for added strength, whereas environments with aesthetic considerations might prefer aluminum for its sleek finish. A trust-building aspect of swage locked grating use is the assurance it provides through compliance with industrial standards. Generally, these gratings meet or exceed regulatory requirements, providing further assurance to managers and stakeholders responsible for safety and quality assurance in industrial operations. In conclusion, swage locked grating is a synthesis of engineering excellence and functional design. For industries looking for reliable, versatile, and maintenance-friendly solutions, it stands as an authoritative choice highly recommended by experts in material engineering and industrial safety. Ultimately, its adoption can lead to significant advantages in terms of durability, safety, and aesthetic appeal, representing a vital component in the success and efficiency of diverse projects.

Share

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025