- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sau . 20, 2025 13:43

Back to list

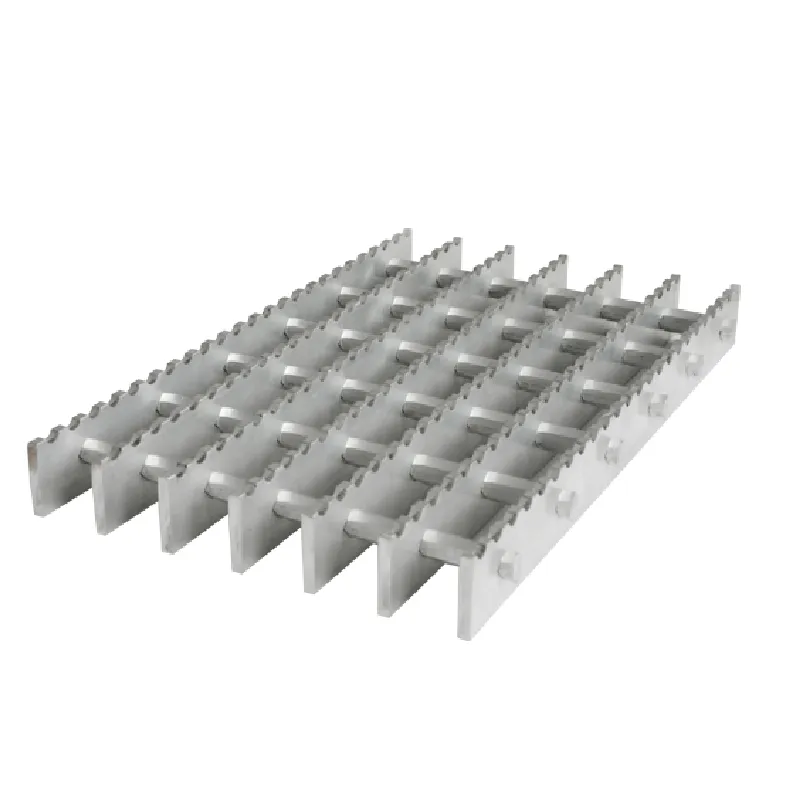

Steel Grating

Aluminum grating is a material of choice across numerous industries thanks to its remarkable properties such as corrosion resistance, lightweight construction, and high strength-to-weight ratio. This versatile component can be found in a myriad of applications, from industrial flooring to architectural facades. With the growing demand for more efficient and sustainable building materials, understanding the specifications of aluminum grating becomes essential for architects, engineers, and project managers alike.

For those requiring specific environmental considerations, aluminum grating's corrosion resistance makes it a prime candidate, particularly in settings exposed to moisture or harsh chemicals. Its natural oxide layer acts as a protective barrier, significantly reducing the degradation experienced by other metals such as steel. Moreover, the choice of alloy can further tailor this resistance, with certain aluminum grades offering enhanced protection even in the most aggressive environments. When considering finish and aesthetic, manufacturers often provide several options, including mill finish, anodized, or powder-coated surfaces. Anodizing not only increases corrosion resistance but also allows for a range of colors to match design requirements. Powder coating adds an additional protective layer, enhancing durability while providing a polished, consistent appearance. Traceability and compliance with industry standards such as the American National Standards Institute (ANSI) or the Occupational Safety and Health Administration (OSHA) are also crucial in ensuring that aluminum grating meets required safety and performance levels. Documentation and certification from manufacturers provide assurance of quality and adherence to relevant guidelines. Understanding aluminum grating specifications requires both technical insight and practical consideration. Whether it’s ensuring the correct load bearing capacity, selecting the appropriate spacing for a specific application, or choosing the right finishing process, each decision contributes significantly to the success of a project. Engaging with experts and leveraging comprehensive data allows for informed choices that merge functionality with aesthetics, delivering solutions that are both efficient and visually pleasing. With its robust characteristics and customizable features, aluminum grating remains an authoritative choice for those seeking reliability and performance in their construction or renovation ventures.

For those requiring specific environmental considerations, aluminum grating's corrosion resistance makes it a prime candidate, particularly in settings exposed to moisture or harsh chemicals. Its natural oxide layer acts as a protective barrier, significantly reducing the degradation experienced by other metals such as steel. Moreover, the choice of alloy can further tailor this resistance, with certain aluminum grades offering enhanced protection even in the most aggressive environments. When considering finish and aesthetic, manufacturers often provide several options, including mill finish, anodized, or powder-coated surfaces. Anodizing not only increases corrosion resistance but also allows for a range of colors to match design requirements. Powder coating adds an additional protective layer, enhancing durability while providing a polished, consistent appearance. Traceability and compliance with industry standards such as the American National Standards Institute (ANSI) or the Occupational Safety and Health Administration (OSHA) are also crucial in ensuring that aluminum grating meets required safety and performance levels. Documentation and certification from manufacturers provide assurance of quality and adherence to relevant guidelines. Understanding aluminum grating specifications requires both technical insight and practical consideration. Whether it’s ensuring the correct load bearing capacity, selecting the appropriate spacing for a specific application, or choosing the right finishing process, each decision contributes significantly to the success of a project. Engaging with experts and leveraging comprehensive data allows for informed choices that merge functionality with aesthetics, delivering solutions that are both efficient and visually pleasing. With its robust characteristics and customizable features, aluminum grating remains an authoritative choice for those seeking reliability and performance in their construction or renovation ventures.

Share

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025