- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ກ.ພ. . 15, 2025 02:07

Back to list

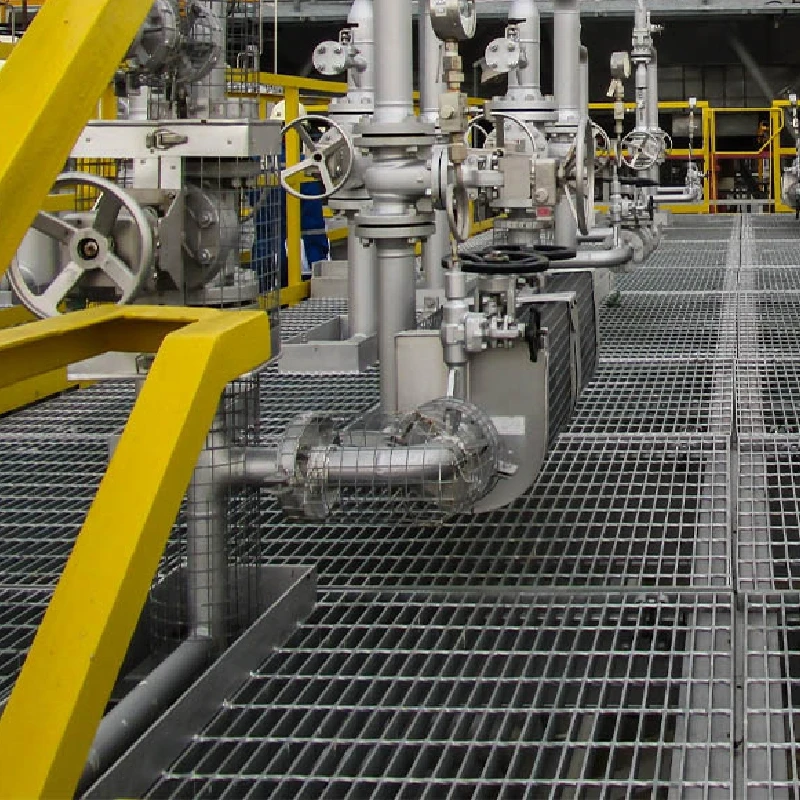

steel walkway grating

In industries ranging from construction to manufacturing, the utilization of galvanized steel grating is both extensive and paramount due to its durability and versatility. The importance of understanding standard sizes in this context cannot be understated, as they directly impact both the effectiveness and the efficiency of projects. This article delves into the specifics of standard sizes in galvanized steel grating, filling an essential gap by offering practical insights derived from real-world experiences and expert knowledge.

Another critical aspect is the mesh size, referring to the spacing between the bars. It's typically measured as the distance between the centers of two adjacent bars. Standard mesh sizes include dimensions like 30x30mm, 40x40mm, and 60x60mm. The selection of mesh size is pivotal; too large a mesh might compromise safety, while too compact might be unnecessarily heavy and costly for certain applications. The spacing between cross bars, which run perpendicular to the load-bearing bars, also follows standard measurements, typically ranging from 50mm to 100mm. These measurements are vital for ensuring appropriate support and structural integrity. Each choice influences not only the physical stability but also the functional application, determining whether the grating is suitable for applications requiring high fluid drainage, unrestricted airflow, or debris shedding. The comprehensive understanding of standardized sizing in galvanized steel grating aids in aligning procurement strategies with specific project needs, thereby optimizing material usage and minimizing waste. For professionals within the construction and engineering fields, this knowledge translates to enhanced project outcomes, from reduced costs and improved timelines to safer, longer-lasting installations. In summary, galvanized steel grating, available in a variety of standardized sizes, offers robust solutions for a multitude of heavy-duty applications. The attention to detail in specification - from panel size and load-bearing bar dimensions to mesh size and bar spacing - ensures that each application benefits from its proprietary blend of strength, economy, and efficiency. Professionals leveraging these standardized dimensions can expect to achieve superior results, driven by an informed understanding that combines industry expertise with practical application. This synthesis of knowledge reflects not only on the individual project but also on the broader field's commitment to innovation and excellence in materials engineering.

Another critical aspect is the mesh size, referring to the spacing between the bars. It's typically measured as the distance between the centers of two adjacent bars. Standard mesh sizes include dimensions like 30x30mm, 40x40mm, and 60x60mm. The selection of mesh size is pivotal; too large a mesh might compromise safety, while too compact might be unnecessarily heavy and costly for certain applications. The spacing between cross bars, which run perpendicular to the load-bearing bars, also follows standard measurements, typically ranging from 50mm to 100mm. These measurements are vital for ensuring appropriate support and structural integrity. Each choice influences not only the physical stability but also the functional application, determining whether the grating is suitable for applications requiring high fluid drainage, unrestricted airflow, or debris shedding. The comprehensive understanding of standardized sizing in galvanized steel grating aids in aligning procurement strategies with specific project needs, thereby optimizing material usage and minimizing waste. For professionals within the construction and engineering fields, this knowledge translates to enhanced project outcomes, from reduced costs and improved timelines to safer, longer-lasting installations. In summary, galvanized steel grating, available in a variety of standardized sizes, offers robust solutions for a multitude of heavy-duty applications. The attention to detail in specification - from panel size and load-bearing bar dimensions to mesh size and bar spacing - ensures that each application benefits from its proprietary blend of strength, economy, and efficiency. Professionals leveraging these standardized dimensions can expect to achieve superior results, driven by an informed understanding that combines industry expertise with practical application. This synthesis of knowledge reflects not only on the individual project but also on the broader field's commitment to innovation and excellence in materials engineering.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025