- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring the Innovations and Applications of Shaker Screens in Modern Industrial Processes

Understanding Shaker Screens Essential Tools for the Oil and Gas Industry

Shaker screens are vital components in the oil and gas industry, particularly in the drilling process. These screens are designed to separate different materials, most notably the solid particles from the drilling fluid, also known as mud. Given their crucial role, it's essential to understand how these screens work, their types, and their importance in maintaining operational efficiency.

The Function of Shaker Screens

At its core, the primary function of shaker screens is to filter out unwanted solids from the drilling fluid that is circulated during the drilling process. The drilling fluid serves multiple purposes—it cools and lubricates the drill bit, carries the cuttings to the surface, and maintains pressure in the wellbore. However, as drilling progresses, the fluid collects a variety of solid materials, including rock cuttings and dirt. This is where shaker screens come into play.

When the drilling fluid is pumped from the well, it passes over the shaker screens, where the solid particles are retained while the clean fluid flows through the screen's mesh. By doing this, shaker screens help in maintaining the viscosity and density of the drilling fluid, ensuring that it performs optimally throughout the drilling operation.

Types of Shaker Screens

Shaker screens come in various types and configurations. The most common types are made of woven wire mesh, perforated plates, or composite materials. The choice of screen depends on numerous factors, including the size of the solid particles that need to be removed, the type of drilling fluid, and the overall drilling conditions.

1. Woven Wire Mesh Screens These screens are made of stainless steel or other durable materials. They are versatile and can be designed to target specific particle sizes.

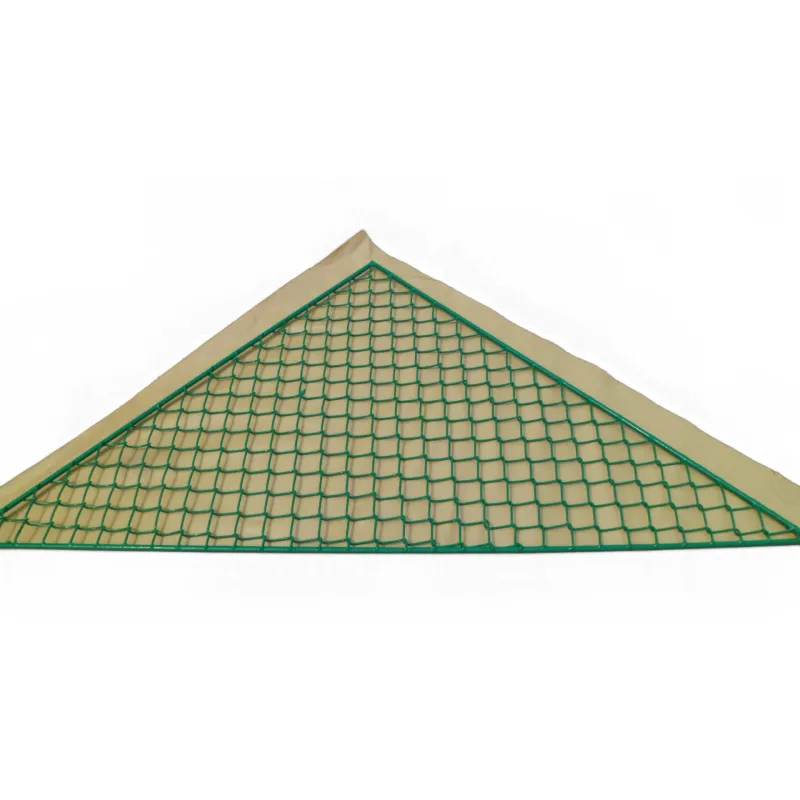

shaker screens

2. Perforated Plate Screens These screens are made of a solid plate with holes punched through. They are more robust and are often used in environments where higher durability is required.

3. Composite Screens A blend of materials, composite screens offer various advantages, such as reduced weight and improved flexibility while maintaining strength.

Importance in Drilling Operations

The efficiency of shaker screens directly impacts the overall drilling operation. An effective shaker screen can significantly reduce the amount of solids in the drilling fluid. This, in turn, prolongs the life of the fluid and minimizes the frequency of mud changes, which can be costly and time-consuming. Additionally, maintaining optimal fluid properties reduces the risk of wellbore instability, something that can lead to costly downtime and repairs.

Moreover, shaker screens play a role in environmental sustainability. By ensuring that the drilling fluid is effective and clean, they help minimize the environmental impact of drilling operations. Effective solid waste management reduces the risk of contamination and helps companies comply with stringent environmental regulations.

Conclusion

In summary, shaker screens are indispensable components of the oil and gas drilling process. They enable the efficient separation of solids from drilling fluids, thereby ensuring operational efficiency and environmental compliance. As the industry evolves and embraces technological advancements, the design and functionality of shaker screens are also expected to improve, leading to even more effective drilling operations. For those involved in drilling, understanding and selecting the right shaker screen is pivotal to achieving operational excellence and minimizing costs in this demanding industry.

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025