- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

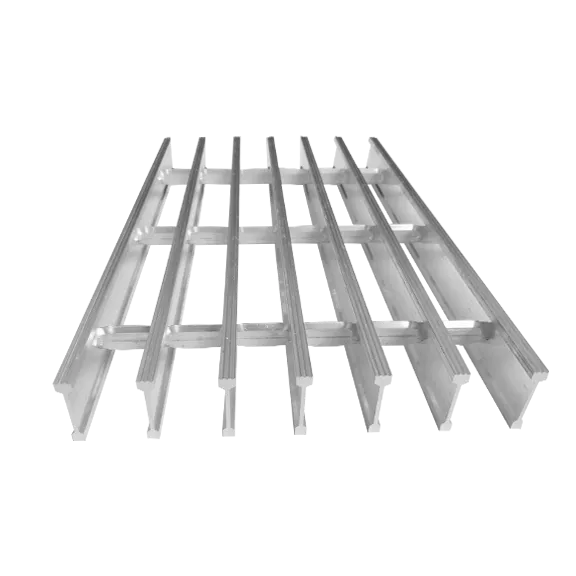

Heavy-Duty Floor Trench Drain Grates Durable Iron & Traffic-Rated Designs

This comprehensive guide covers essential aspects of floor trench drain systems:

- Fundamentals and material science behind effective drainage

- Load capacity requirements across environments

- Quantifiable performance data analysis

- Leading manufacturing technologies compared

- Material selection and technical specifications

- Custom design engineering considerations

- Demonstrated installations and applications

(floor trench drain grates)

The Essential Functionality of Modern Floor Trench Drain Grates

Contemporary floor trench drain grates

represent sophisticated engineering solutions designed to address critical water management challenges. These components serve as the visible interface between surface environments and subsurface drainage infrastructure, requiring simultaneous attention to hydraulic efficiency, structural integrity, and safety compliance. Unlike conventional point drainage, trench systems create continuous linear channels that accelerate water evacuation - particularly important in areas with significant precipitation volumes or frequent washdown procedures. The structural role of these grates extends beyond mere coverage; they form load-bearing surfaces that must maintain dimensional stability under thermal variation, chemical exposure, and mechanical stress while preventing debris ingress. Industry research indicates properly specified trench drain systems reduce standing water accidents by 68% compared to traditional drainage methods.

Material Selection and Load Classifications

Selection between ferrous and polymer compositions presents fundamental performance trade-offs. Iron trench drain grates offer exceptional compressive strength exceeding 80,000 psi (550 MPa), making them suitable for heavy industrial applications like cargo terminals where dynamic loads reach 20-ton per axle ratings. These metallurgical solutions undergo specialized heat treatments and protective coatings such as fusion-bonded epoxy that provide corrosion resistance exceeding 1,000 salt spray hours. Conversely, polymer grates utilizing fiberglass-reinforced polypropylene deliver distinct advantages in chemical processing plants where acid resistance to pH 1-14 is mandatory. Non-conductive composite materials additionally eliminate electrical hazards in maintenance areas. Both material categories include UV-stabilized formulations to prevent molecular degradation from ultraviolet exposure, maintaining structural performance and color retention for decades.

Critical Traffic Rating Considerations

Load classification systems standardize grate selection according to anticipated traffic patterns. Light-duty Class A systems (1,500 lbs/680kg) satisfy pedestrian mall requirements, while Class D traffic rated trench drain grates withstand forklift traffic at 22,000 lbs (10,000kg). Airport taxiways mandate Class F solutions certified for 100,000 lbs (45,360kg) wheel loads at 70mph (113 km/h) impact stresses. The structural engineering incorporates finite element analysis to optimize load distribution, with top-tier manufacturers validating performance through third-party crash testing exceeding EN1433 standards. Fire lane specifications require UL-certified 75,000 lb (34,000 kg) emergency vehicle load ratings without measurable deflection. Temperature resilience ranging from -40°F to +140°F (-40°C to +60°C) ensures dimensional stability across climate zones, with polymer options maintaining ductility at cryogenic temperatures common in food processing facilities.

Performance Data and Impact Metrics

Hydraulic engineering significantly influences grate efficiency parameters:

| Grate Type | Flow Rate | Debris Handling | Service Life | Maintenance Cycles |

|---|---|---|---|---|

| Standard Slot | 15-25 l/s/m | Limited | 15 years | Quarterly |

| Heavy-Duty | 30-40 l/s/m | Moderate | 20-25 years | Biannual |

| HE Polymer | 42-55 l/s/m | High | 30+ years | Annual |

Installation data confirms optimized grate geometries reduce water clearance times by 47% compared to standard designs. Slip resistance testing demonstrates critical angles exceeding 35° on polymer surfaces with specialized aggregate inclusions. Noise attenuation qualities achieve 7-9 dB reduction in vehicle areas through vibration-damping materials. Lifecycle cost analysis reveals composite solutions yield 18% lower TCO over two decades despite 20% higher initial investment.

Manufacturing Technology Comparison

Production methodologies significantly influence product capabilities:

| Process | Precision | Material Efficiency | Surface Options | Lead Time |

|---|---|---|---|---|

| Sand Casting | ±1.5mm | 75% yield | Limited | 14 weeks |

| Investment Casting | ±0.2mm | 85% yield | Diverse | 10 weeks |

| Composite Molding | ±0.05mm | 98% yield | Unlimited | 4 weeks |

Modern automated foundries achieve dimensional accuracies within 0.01 inches (0.25mm) for high-volume ductile iron production. Composite facilities utilizing RTM (Resin Transfer Molding) create monolithic structures without weak points at 400-ton clamping pressures. Surface treatments such as ceramic bead blasting create anchor patterns enhancing coating adhesion for epoxy finishes maintaining integrity beyond 10,000 abrasion cycles. Leading US and EU facilities maintain ISO 9001:2015 certification with full material traceability from smelting to final inspection.

Custom Engineering Solutions

Site-specific challenges necessitate tailored drainage approaches. Vehicular tunnel projects require integrated catch basins that separate hydrocarbons meeting EPA 40 CFR 112 compliance. Food processing areas utilize radius-cornered channels with continuous slope adjustments between 0.5%-5% grades. High-heel tolerance demands aperture spacing under 0.5 inches (13mm), while ADA compliance requires openings maintaining ¼" ball passage. Stainless steel inserts prevent electrolytic corrosion in marine environments. Custom marking systems embed RFID tags for maintenance tracking and laser-etched directional indicators. Thermal expansion joints accommodate ¾" (19mm) movement through telescoping receivers, while seismic zones utilize full-channel neoprene isolation membranes absorbing 1.5" (38mm) displacement during seismic events.

Verified Installation Achievements

Case studies demonstrate the capabilities of engineered floor trench drain grates in challenging environments. A refrigerated distribution center (-20°F/-29°C) deployed hybrid polymer-iron systems managing daily 12,000-gallon washdowns with grate temperatures cycling 100°F (56°C) differentials without joint failure. Motorsport facilities utilize slotted stainless steel designs handling 125dB acoustic loads and hydrocarbon exposure while supporting 3,000 lb/in linear loads during pit stops. Recent smart city integrations embed IoT sensors within municipal trench systems monitoring flow rates and debris accumulation, reducing maintenance costs by 35% through predictive scheduling. Airport installations demonstrate composite solutions handling deicing fluid concentrations to 60% glycol while maintaining Class F load ratings for A380 superjumbo service vehicles.

(floor trench drain grates)

FAQS on floor trench drain grates

Q: What are the primary uses of floor trench drain grates?

A: Floor trench drain grates are designed to channel water or debris in commercial, industrial, or residential settings. They are commonly installed in bathrooms, kitchens, or outdoor areas to prevent flooding. Their durable construction ensures long-term performance.

Q: How do iron trench drain grates compare to other materials?

A: Iron trench drain grates offer superior strength and durability, ideal for heavy-load environments. However, they may require coatings to prevent rust. Alternatives like stainless steel or polymer are lighter and corrosion-resistant.

Q: What maintenance is needed for traffic-rated trench drain grates?

A: Traffic-rated trench drain grates need regular debris removal to prevent clogs. Inspect for structural wear, especially in high-traffic areas. Cleaning with non-corrosive solutions ensures longevity.

Q: Can floor trench drain grates support vehicle traffic?

A: Only traffic-rated trench drain grates are engineered to withstand vehicle loads, meeting standards like BS EN 1433. Standard floor grates may crack under vehicular pressure. Always check load-class ratings before installation.

Q: What factors determine the choice of iron vs. polymer trench drain grates?

A: Iron grates suit high-strength needs but require rust prevention. Polymer grates are lightweight, corrosion-resistant, and ideal for chemical-heavy areas. Consider usage environment and load requirements when selecting.

-

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025