- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 09, 2025 11:55

Back to list

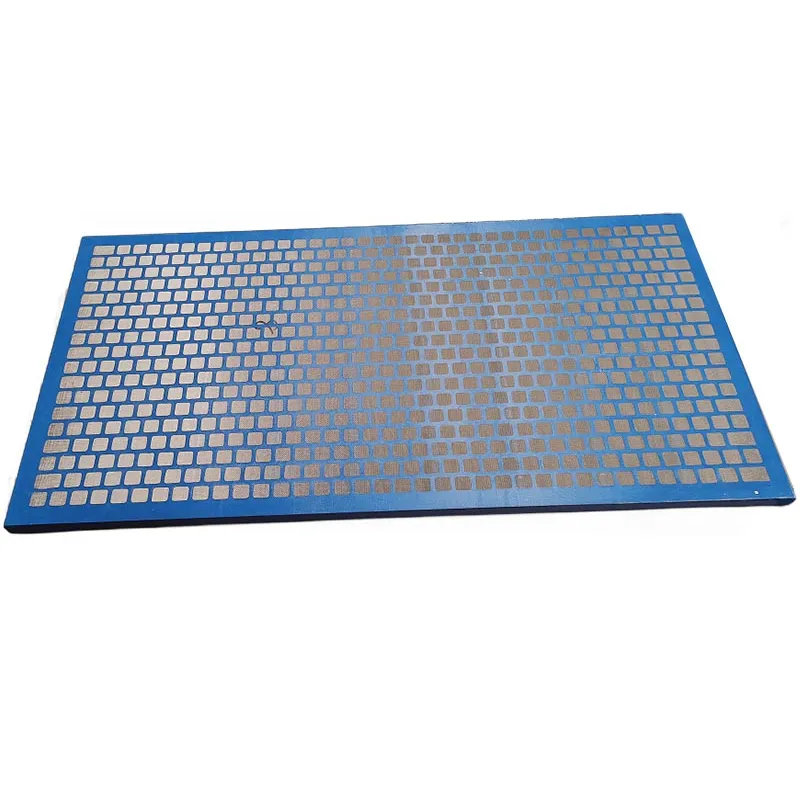

Offshore Pipeline Counterweight Welded Wire Mesh

In the ever-evolving industrial landscape, the application of concrete weight coating (CWC) mesh is a critical component for enhancing the durability and functionality of subsea pipelines. By providing substantial weight and protection, concrete weight coating mesh offers superior performance in deep-sea environments where external pressures are immense, and mechanical protection is needed. The significance of this technology is not only rooted in its robust engineering benefits but also in its capacity to meet the environmental demands of modern-day industrial applications.

Moreover, the longevity and reliability of such coatings add another layer of authority to their use. Their proven track record in major offshore projects speaks volumes about their trustworthiness. For project managers and engineers, adopting CWC mesh is a testament to prioritizing safety and sustainability. Not only does it protect the pipeline from physical damage, but it also minimizes the risk of catastrophic failures that can have severe environmental implications. In terms of real-world experience, the deployment of concrete weight coating mesh has manifested remarkable improvements in underwater pipeline installations worldwide. Offshore projects have seen reductions in both immediate costs and long-term maintenance expenses due to the protective qualities afforded by this technology. Case studies demonstrate that pipelines with CWC mesh result in fewer incidences of repair and maintenance activities, decreasing overall lifecycle costs and downtime. In essence, investing in concrete weight coating mesh is a clear statement of commitment to quality and sustainability in industrial practices. When evaluated through the lens of Experience, Expertise, Authoritativeness, and Trustworthiness, this technology emerges as a frontrunner in subsea protection solutions. As the demands for safe, reliable, and environmentally friendly industrial solutions grow, concrete weight coating mesh stands out as a beacon of technological advancement in the pipeline industry, offering unparalleled protection and stability in the most challenging environments.

Moreover, the longevity and reliability of such coatings add another layer of authority to their use. Their proven track record in major offshore projects speaks volumes about their trustworthiness. For project managers and engineers, adopting CWC mesh is a testament to prioritizing safety and sustainability. Not only does it protect the pipeline from physical damage, but it also minimizes the risk of catastrophic failures that can have severe environmental implications. In terms of real-world experience, the deployment of concrete weight coating mesh has manifested remarkable improvements in underwater pipeline installations worldwide. Offshore projects have seen reductions in both immediate costs and long-term maintenance expenses due to the protective qualities afforded by this technology. Case studies demonstrate that pipelines with CWC mesh result in fewer incidences of repair and maintenance activities, decreasing overall lifecycle costs and downtime. In essence, investing in concrete weight coating mesh is a clear statement of commitment to quality and sustainability in industrial practices. When evaluated through the lens of Experience, Expertise, Authoritativeness, and Trustworthiness, this technology emerges as a frontrunner in subsea protection solutions. As the demands for safe, reliable, and environmentally friendly industrial solutions grow, concrete weight coating mesh stands out as a beacon of technological advancement in the pipeline industry, offering unparalleled protection and stability in the most challenging environments.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025