- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 15, 2025 01:05

Back to list

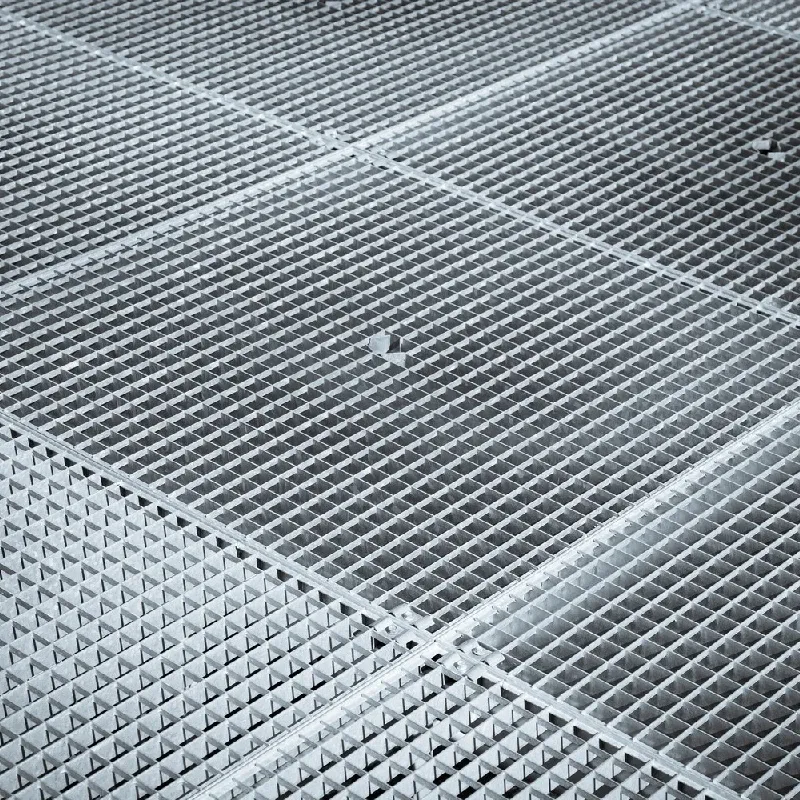

steel grating thickness

Steel grating thickness plays a crucial role in both the functionality and durability of this widely used construction material. Providing an optimal balance between weight and strength, the thickness of steel grating determines its suitability for various applications whether in industrial settings, commercial environments, or public infrastructure projects.

For those looking to balance performance with aesthetic considerations, the choice of grating thickness can also impact the visual appeal of a project. Architectural applications that require a sleek, modern look may opt for perforated steel grating with a thinner profile, allowing for more intricate design patterns while still providing structural integrity and functionality. When consulting with suppliers or manufacturers, it's advisable to discuss the specific environmental conditions and load requirements your project will face. Knowledgeable partners can recommend appropriate grating thicknesses, taking into account factors beyond simple load capacity, such as ease of installation, long-term maintenance, and total cost of ownership. This tailored approach not only enhances the performance and safety of the steel grating but also ensures compliance with any relevant safety or construction codes. Another critical factor influencing the choice of steel grating thickness is its interaction with other materials used in construction. Compatibility with materials such as concrete, wood, or other metals can influence factors such as thermal expansion, which needs to be accounted for during the design phase to prevent issues like warping or structural tension. Trustworthiness in selecting the right steel grating thickness is enhanced by verifying the manufacturer's certifications and reputation within the industry. Engaging with suppliers that have a record of reliability and adherence to international quality standards ensures that the chosen grating will perform as expected, maintaining safety and operational standards over its entire service life. In conclusion, understanding the nuances of steel grating thickness is pivotal for optimizing both performance and cost-efficiency across various applications. By balancing expertise, authoritative insights, and trustworthy manufacturing practices, project stakeholders can secure grating solutions that meet their specific needs while adhering to industry best practices and regulations.

For those looking to balance performance with aesthetic considerations, the choice of grating thickness can also impact the visual appeal of a project. Architectural applications that require a sleek, modern look may opt for perforated steel grating with a thinner profile, allowing for more intricate design patterns while still providing structural integrity and functionality. When consulting with suppliers or manufacturers, it's advisable to discuss the specific environmental conditions and load requirements your project will face. Knowledgeable partners can recommend appropriate grating thicknesses, taking into account factors beyond simple load capacity, such as ease of installation, long-term maintenance, and total cost of ownership. This tailored approach not only enhances the performance and safety of the steel grating but also ensures compliance with any relevant safety or construction codes. Another critical factor influencing the choice of steel grating thickness is its interaction with other materials used in construction. Compatibility with materials such as concrete, wood, or other metals can influence factors such as thermal expansion, which needs to be accounted for during the design phase to prevent issues like warping or structural tension. Trustworthiness in selecting the right steel grating thickness is enhanced by verifying the manufacturer's certifications and reputation within the industry. Engaging with suppliers that have a record of reliability and adherence to international quality standards ensures that the chosen grating will perform as expected, maintaining safety and operational standards over its entire service life. In conclusion, understanding the nuances of steel grating thickness is pivotal for optimizing both performance and cost-efficiency across various applications. By balancing expertise, authoritative insights, and trustworthy manufacturing practices, project stakeholders can secure grating solutions that meet their specific needs while adhering to industry best practices and regulations.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025