- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 25, 2025 06:09

Back to list

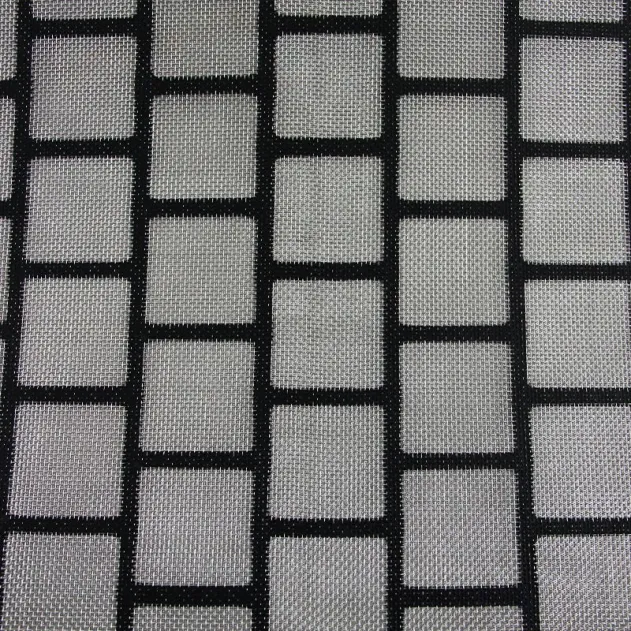

Steel Grating

Understanding the intricacies of platform grating specifications is essential for industries that prioritize safety, durability, and cost-effectiveness. With the myriad of materials and designs available, choosing the right grating for your platform requires a precise approach grounded in substantial expertise and trustworthy data.

Ensuring compliance with industry standards is non-negotiable. Organizations like the American National Standards Institute (ANSI) and Occupational Safety and Health Administration (OSHA) provide guidelines that influence grating selection. Adhering to these regulations not only ensures legal compliance but also fortifies the safety and reliability of the installation. Durability remains a pivotal criterion in selecting platform grating, as endurance against environmental and operational stressors dictates the longevity of the investment. This consideration encompasses both initial cost evaluations and potential long-term savings in maintenance and replacement. Transitioning to custom specifications offers businesses the opportunity to tailor solutions to their exact needs. Customization might involve specific dimensions, load ratings, or surface treatments, which can optimize the grating's performance in its intended environment. Consulting with manufacturers who have a reputable track record in delivering customized grating solutions can elevate the trustworthiness of the purchase decision. Lastly, seamless collaboration between engineers, architects, and grating manufacturers cannot be understated. This triadic partnership ensures that the specifications align meticulously with project objectives, thereby enhancing the platform's safety, efficiency, and cost-effectiveness. Navigating platform grating specifications indeed demands a fusion of experience and expertise. By prioritizing material choice, pattern configuration, compliance standards, and collaborative synergy, industries can ensure that their platform grating serves as a benchmark of safety, reliability, and value. Contributed with the latest innovations and standard guidelines, the comprehensive perspective on grating can surely lead to informed decisions unparalleled by any pre-existing analysis.

Ensuring compliance with industry standards is non-negotiable. Organizations like the American National Standards Institute (ANSI) and Occupational Safety and Health Administration (OSHA) provide guidelines that influence grating selection. Adhering to these regulations not only ensures legal compliance but also fortifies the safety and reliability of the installation. Durability remains a pivotal criterion in selecting platform grating, as endurance against environmental and operational stressors dictates the longevity of the investment. This consideration encompasses both initial cost evaluations and potential long-term savings in maintenance and replacement. Transitioning to custom specifications offers businesses the opportunity to tailor solutions to their exact needs. Customization might involve specific dimensions, load ratings, or surface treatments, which can optimize the grating's performance in its intended environment. Consulting with manufacturers who have a reputable track record in delivering customized grating solutions can elevate the trustworthiness of the purchase decision. Lastly, seamless collaboration between engineers, architects, and grating manufacturers cannot be understated. This triadic partnership ensures that the specifications align meticulously with project objectives, thereby enhancing the platform's safety, efficiency, and cost-effectiveness. Navigating platform grating specifications indeed demands a fusion of experience and expertise. By prioritizing material choice, pattern configuration, compliance standards, and collaborative synergy, industries can ensure that their platform grating serves as a benchmark of safety, reliability, and value. Contributed with the latest innovations and standard guidelines, the comprehensive perspective on grating can surely lead to informed decisions unparalleled by any pre-existing analysis.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025