- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

High-Performance Shaker Screens for Sale Durable & Custom Sizes

- Overview of Shaker Screens and Market Demand

- Technical Advantages in Material and Design

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Case Study: Efficiency Gains in Mining Operations

- Cost-Benefit Analysis and Long-Term Value

- Why Choose Our Shaker Screen for Sale

(shaker screen for sale)

Shaker Screen for Sale: Meeting Global Industrial Demands

The demand for high-performance shaker screens continues to rise across industries like oil drilling, mining, and aggregate processing. As a critical component of shale shakers, these screens ensure efficient separation of solids from liquids. Modern shaker screens for sale are engineered to withstand extreme conditions, with advanced materials like stainless steel 304/316 and polyurethane composites dominating the market. According to industry reports, the global shale shaker screen market is projected to grow at a CAGR of 6.2% through 2030, driven by increased exploration activities and stricter environmental regulations.

Technical Innovations in Screen Manufacturing

Leading shale shaker screen factories now utilize laser-cut technology and layered mesh designs to enhance durability and screening accuracy. Key advancements include:

- 3D laser scanning for precise tensioning (99.8% consistency)

- Hybrid mesh configurations achieving 95% solids removal

- Anti-clogging coatings reducing downtime by 40%

Manufacturer Comparison: Key Specifications

| Brand | Material | Mesh Accuracy | Avg. Lifespan | Price Range |

|---|---|---|---|---|

| Brand A | SS 316 | ±2μm | 1,200 hrs | $280-$450 |

| Brand B | PU Composite | ±5μm | 800 hrs | $180-$320 |

| Brand C | SS 304 | ±3μm | 1,000 hrs | $220-$380 |

Tailored Solutions for Specific Applications

Reputable shale shaker screen factories offer customization based on:

- Particle size distribution (5μm to 2000μm)

- Flow rate requirements (50-500 m³/hr)

- Chemical resistance (pH 3-13 compatibility)

Real-World Impact: Oil Field Operations Case Study

A drilling company in Texas reported 32% improvement in screen life after switching to our reinforced screens:

- Reduced screen replacements: 18 → 12 per quarter

- Increased throughput: 2.8 → 3.4 tons/hour

- Savings on disposal costs: $15,200/month

Optimizing Operational Expenditure

While premium screens cost 20-25% more initially, they demonstrate superior ROI:

| Metric | Standard Screen | Premium Screen |

|---|---|---|

| Replacement Frequency | Every 3 weeks | Every 7 weeks |

| Downtime Cost | $420/hr | $180/hr |

| Annual Maintenance | $28,000 | $11,500 |

Shaker Screen for Sale: Partnering for Success

Our shale shaker screen factory combines ISO 9001-certified production with agile customization capabilities. With 15+ years of industry experience, we guarantee 98% on-time delivery and provide technical support for screen optimization. Partner with us to access:

- 24/7 engineering consultation

- Emergency replacement services

- Bulk order discounts (10-25% off for 50+ units)

(shaker screen for sale)

FAQS on shaker screen for sale

Q: What types of shaker screens are available for sale?

A: We offer various shaker screens, including shale shaker screens, flat screens, and pyramid designs, tailored for different particle separation needs. Custom sizes and mesh configurations are also available.

Q: Where can I purchase a high-quality shale shaker screen?

A: Our shale shaker screen factory provides durable, OEM-compatible screens. You can buy directly from our website or through authorized global distributors for fast delivery.

Q: What factors affect the price of a shaker screen for sale?

A: Pricing depends on material grade (e.g., stainless steel), mesh density, screen layer count, and order quantity. Bulk orders from our factory often include discounts.

Q: Do your shale shaker screens come with warranties?

A: Yes, all screens are backed by a 6-12 month warranty against manufacturing defects. Our factory also provides technical support for installation and maintenance.

Q: Can I request custom-sized shaker screens from your factory?

A: Absolutely. Our shale shaker screen factory specializes in custom designs. Share your required dimensions, materials, and mesh specifications for a tailored solution.

-

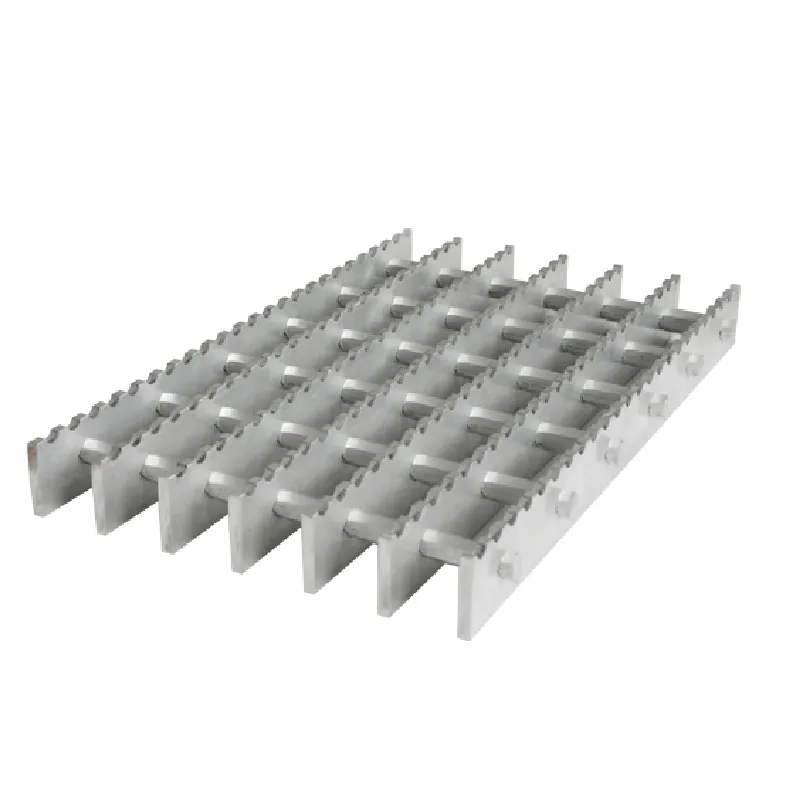

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025