- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

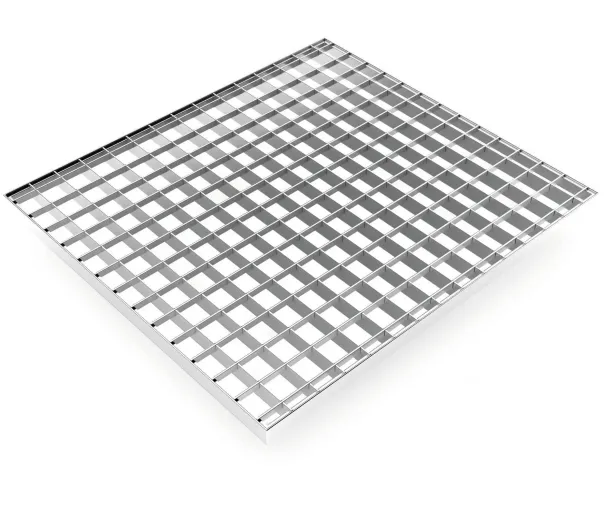

grating galvanized steel

The Versatility and Benefits of Grating Galvanized Steel

Grating galvanized steel has emerged as a popular choice in various industries due to its unique combination of strength, durability, and resistance to corrosion. This material is primarily made from steel that undergoes a galvanization process, where zinc is applied to the surface to create a protective coating. This process not only enhances the steel's lifespan but also increases its aesthetic appeal.

One of the main advantages of using grating galvanized steel is its remarkable strength-to-weight ratio. Steel is known for being one of the strongest construction materials available, and when it is designed in a grating format, it can withstand heavy loads while being lightweight. This property makes it ideal for applications such as flooring, walkways, and industrial platforms, where safety is paramount, and high foot or equipment traffic is expected. The open grid design allows for maximum support with minimal material use, making it an economical choice for large projects.

In addition to structural integrity, galvanized steel grating offers excellent slip resistance. This is particularly important in environments prone to spills or where moisture is present, such as industrial sites, food processing plants, and commercial kitchens. The surface of the grating can be designed with various patterns and finishes to enhance traction, reducing the likelihood of accidents and ensuring safety for workers.

grating galvanized steel

Corrosion resistance is another critical benefit of grating galvanized steel. The galvanization process coats the steel with a barrier that prevents rust and degradation from environmental factors such as moisture, humidity, and corrosive chemicals. This is vital in sectors such as construction, mining, and wastewater management, where materials are often exposed to harsh conditions. Using galvanized steel not only prolongs the lifespan of the product but also reduces maintenance costs, making it a cost-effective investment.

Environmental considerations are increasingly important in modern construction and manufacturing. Grating galvanized steel is often made from recycled materials and is itself recyclable at the end of its life cycle. This aligns with sustainable practices, helping companies reduce their carbon footprint and promote environmental stewardship.

Another aspect that enhances its appeal is the ease of installation. Grating galvanized steel products are pre-fabricated and can be easily customized to fit specific requirements. This saves time during the installation process, allowing projects to stay on schedule and within budget.

In conclusion, grating galvanized steel serves as a robust solution for numerous applications across various industries. Its strength, lightweight nature, slip resistance, corrosion protection, and eco-friendliness make it an exceptional choice for architects, builders, and engineers. As industries continue to prioritize safety and sustainability, the demand for grating galvanized steel is only expected to grow, making it a staple in modern construction and infrastructure projects. Whether for industrial flooring, walkways, or drainage solutions, this versatile material demonstrates that functionality can coexist with durability and efficiency.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025