- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 14, 2025 17:54

Back to list

Offshore Pipeline Counterweight Welded Wire Mesh

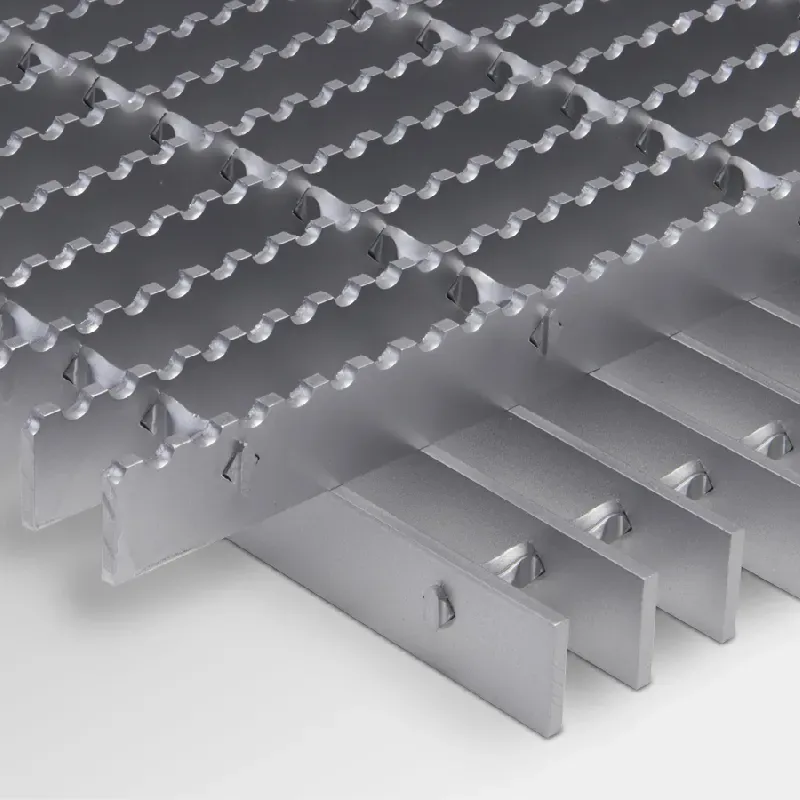

Exploring the Details Grating 32x5 Weight and Its Significance in Various Industries

In public infrastructure projects, such as bridges and train stations, these gratings offer durability and low maintenance requirements, contributing to long service life without recurrent costly repairs. Their capability to withstand harsh weather and resist corrosion makes them an excellent choice for outdoor and industrial environments. Expert Opinions on Grating 32x5 Weight Industry experts assert that the optimal selection of grating should be based on a comprehensive understanding of the specific application requirements. According to John Stevens, a civil engineer with two decades of experience in infrastructure design, the decision on grating should consider factors such as environmental conditions, expected load, and anticipated wear and tear. He emphasizes that neglecting these considerations could lead to underperformance, accidents, or premature structural failures. Hence, in projects where human safety and significant investments are involved, utilizing expert insights during the selection phase is indispensable. Trust and Quality in Procurement Ensuring credibility and trust when procuring 32x5 gratings involves verifying the supplier's reputation, material certification, and quality assurance processes. Companies known for adhering to international standards and offering consistent after-sales support are often preferred. Michael Adams, an experienced procurement specialist, advises that establishing long-term collaborations with reputable suppliers can ensure quality continuity, technical support, and innovation in grating solutions. This collaborative approach aids in aligning the grating’s weight and specifications with industry needs and safety standards. Conclusion Understanding the intricacies of grating 32x5 weight is essential for any industry relying on durable, safe, and efficient structural components. By factoring in detailed specifications, expert inputs, and rigorous quality checks, industries can ensure that the grating they choose not only meets their operational demands but also enhances the safety and efficiency of their projects. As the landscape of engineering and construction continues to evolve, staying informed about key material parameters remains a pivotal aspect of successful project execution.

In public infrastructure projects, such as bridges and train stations, these gratings offer durability and low maintenance requirements, contributing to long service life without recurrent costly repairs. Their capability to withstand harsh weather and resist corrosion makes them an excellent choice for outdoor and industrial environments. Expert Opinions on Grating 32x5 Weight Industry experts assert that the optimal selection of grating should be based on a comprehensive understanding of the specific application requirements. According to John Stevens, a civil engineer with two decades of experience in infrastructure design, the decision on grating should consider factors such as environmental conditions, expected load, and anticipated wear and tear. He emphasizes that neglecting these considerations could lead to underperformance, accidents, or premature structural failures. Hence, in projects where human safety and significant investments are involved, utilizing expert insights during the selection phase is indispensable. Trust and Quality in Procurement Ensuring credibility and trust when procuring 32x5 gratings involves verifying the supplier's reputation, material certification, and quality assurance processes. Companies known for adhering to international standards and offering consistent after-sales support are often preferred. Michael Adams, an experienced procurement specialist, advises that establishing long-term collaborations with reputable suppliers can ensure quality continuity, technical support, and innovation in grating solutions. This collaborative approach aids in aligning the grating’s weight and specifications with industry needs and safety standards. Conclusion Understanding the intricacies of grating 32x5 weight is essential for any industry relying on durable, safe, and efficient structural components. By factoring in detailed specifications, expert inputs, and rigorous quality checks, industries can ensure that the grating they choose not only meets their operational demands but also enhances the safety and efficiency of their projects. As the landscape of engineering and construction continues to evolve, staying informed about key material parameters remains a pivotal aspect of successful project execution.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025