- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Innovative Pipeline Reinforcement Solutions Utilizing Advanced Mesh Technology for Enhanced Structural Integrity

The Importance of Pipeline Reinforced Mesh in Modern Infrastructure

In the realm of civil engineering and construction, innovative materials play a crucial role in enhancing the durability and longevity of infrastructures. One such material that has gained traction in recent years is pipeline reinforced mesh. This sophisticated solution combines traditional reinforcement with modern engineering principles, creating a robust framework that significantly improves the integrity of various pipeline systems.

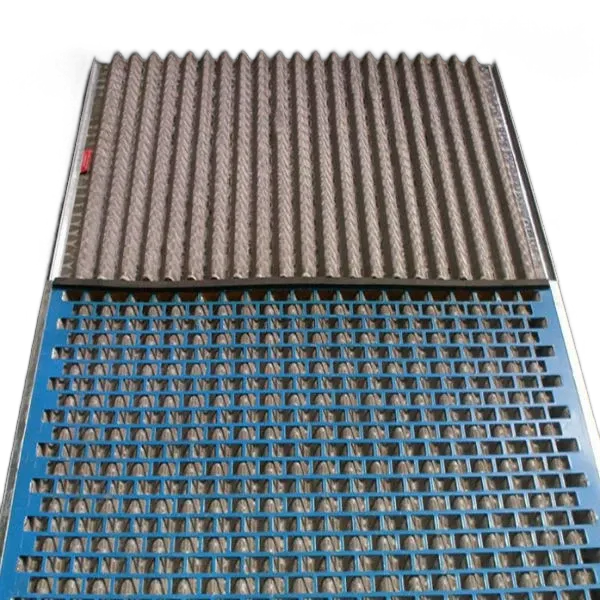

What is Pipeline Reinforced Mesh?

Pipeline reinforced mesh consists of a series of interconnected steel or synthetic fibers arranged in a grid pattern. This mesh is designed to be integrated into the walls of pipelines, providing additional support and resistance against various forces that may compromise the pipeline's structural integrity. The use of reinforced mesh is particularly beneficial in various applications, including water, sewage, and gas transportation systems.

Advantages of Using Reinforced Mesh

1. Enhanced Structural Integrity The primary advantage of utilizing pipeline reinforced mesh is its ability to distribute stress more evenly across the surface of the pipeline. This prevents localized failures that might occur due to pressure fluctuations, soil movement, or external impacts.

2. Resistance to Corrosion Modern reinforced meshes are often treated with protective coatings that enhance their resistance to corrosion. This is particularly important for pipelines that transport corrosive substances or operate in harsh environmental conditions. The longevity of the pipeline is significantly increased, reducing the frequency of repairs and replacements.

3. Improved Load-Bearing Capacity Reinforced mesh adds to the tensile strength of the pipeline, allowing it to bear heavier loads without deforming. This is particularly essential in urban areas where pipelines may be located beneath roads or high-traffic zones.

pipeline reinforced mesh

4. Cost-Effectiveness While the initial investment in pipeline reinforced mesh may be higher than traditional methods, the long-term savings are substantial. The reduced need for repairs, coupled with the extended lifecycle of the pipelines, leads to lower maintenance costs over time.

5. Facilitates Installation Pipeline reinforced mesh can be prefabricated according to specific project requirements, making installation quicker and more efficient. This results in reduced disruption during construction, which is especially advantageous in densely populated areas.

Applications in Various Industries

The versatility of pipeline reinforced mesh extends across multiple industries. In the water sector, it is employed to enhance the reliability of drinking water distribution systems. In wastewater management, the reinforced mesh helps in preventing leaks and ensuring that the system operates efficiently under pressure. Furthermore, the gas industry benefits from the increased safety that reinforced pipeline systems offer, mitigating the risks associated with leaks or bursts.

Future Trends

As technology continues to evolve, the future of pipeline reinforced mesh looks promising. Ongoing research focuses on integrating smart technologies that can monitor the health of pipeline systems in real-time. Sensors embedded within the mesh can provide valuable data regarding stress levels and potential weaknesses, allowing for proactive maintenance and management of pipeline infrastructure.

Conclusion

In summary, pipeline reinforced mesh represents a significant advancement in pipeline construction and maintenance. Its ability to enhance structural integrity, resist corrosion, and improve load-bearing capacity makes it an invaluable asset in modern infrastructure development. As industries seek sustainable and durable solutions, the integration of reinforced mesh into pipeline systems is poised to become a standard practice, paving the way for safer and more reliable infrastructure worldwide. As we continue to innovate and adapt, pipeline reinforced mesh will undoubtedly play a key role in ensuring the resilience of our essential utilities for generations to come.

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025