- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

شوبات . 12, 2025 12:37

Back to list

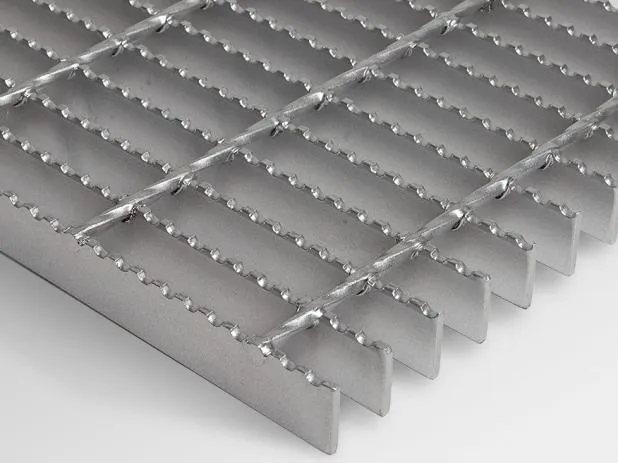

Steel Grating

When you're considering the right materials for a construction or renovation project, galvanized plank grating emerges as a popular choice due to its durability and practicality. In the modern construction industry, safety, longevity, and cost-efficiency are key factors that professionals must consider. Galvanized plank grating offers significant advantages across these dimensions, making it an ideal solution for a multitude of applications.

From a technical standpoint, expertise in the handling and installation of galvanized plank grating is crucial. Incorrect handling can compromise its protective zinc coating, leading to premature wear. Installation demands precise calculations and cutting, requiring experienced professionals to ensure that the grating fits securely and operates optimally. It’s also crucial to select the right gauge and size for the intended application to avoid common pitfalls such as deflection under load or misalignment during installation. In terms of maintenance, the trustworthiness of galvanized plank grating is further demonstrated by its low upkeep. Unlike untreated materials, which might require regular painting or more frequent inspections and repairs, galvanized grating primarily involves routine checks. These checks are essential for ensuring that the zinc coating remains intact and that no damage has occurred. When established maintenance protocols are adhered to, the lifespan of galvanized plank grating can extend significantly, offering excellent return on investment. For businesses considering incorporating galvanized plank grating into their operations, understanding supplier credentials is equally important. A reliable provider should offer product certifications and compliance with industry standards, ensuring that the materials meet all required safety and quality benchmarks. It's also beneficial to seek suppliers who offer a range of customization options, allowing businesses to procure grating that meets specific project requirements. In summary, galvanized plank grating not only meets but exceeds the criteria of Experience, Expertise, Authoritativeness, and Trustworthiness in product selection for industrial and commercial projects. Firms investing in this material gain a durable solution resilient to environmental challenges, backed by robust safety features and cost-effectiveness over the long term. Whether used in heavy industry or contemporary architectural designs, the versatility and strength of galvanized plank grating make it an indispensable component for professionals aiming to achieve excellence in their projects.

From a technical standpoint, expertise in the handling and installation of galvanized plank grating is crucial. Incorrect handling can compromise its protective zinc coating, leading to premature wear. Installation demands precise calculations and cutting, requiring experienced professionals to ensure that the grating fits securely and operates optimally. It’s also crucial to select the right gauge and size for the intended application to avoid common pitfalls such as deflection under load or misalignment during installation. In terms of maintenance, the trustworthiness of galvanized plank grating is further demonstrated by its low upkeep. Unlike untreated materials, which might require regular painting or more frequent inspections and repairs, galvanized grating primarily involves routine checks. These checks are essential for ensuring that the zinc coating remains intact and that no damage has occurred. When established maintenance protocols are adhered to, the lifespan of galvanized plank grating can extend significantly, offering excellent return on investment. For businesses considering incorporating galvanized plank grating into their operations, understanding supplier credentials is equally important. A reliable provider should offer product certifications and compliance with industry standards, ensuring that the materials meet all required safety and quality benchmarks. It's also beneficial to seek suppliers who offer a range of customization options, allowing businesses to procure grating that meets specific project requirements. In summary, galvanized plank grating not only meets but exceeds the criteria of Experience, Expertise, Authoritativeness, and Trustworthiness in product selection for industrial and commercial projects. Firms investing in this material gain a durable solution resilient to environmental challenges, backed by robust safety features and cost-effectiveness over the long term. Whether used in heavy industry or contemporary architectural designs, the versatility and strength of galvanized plank grating make it an indispensable component for professionals aiming to achieve excellence in their projects.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025