- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Affordable Aluminum Grating Price Durable & Low-Cost Solutions

- The Current Market Overview of Aluminum Grating Price

- Technical Advantages Driving Material Selection

- Comparative Pricing Analysis Across Materials

- Key Manufacturer Landscape and Value Analysis

- Customization Variables Impacting Final Pricing

- Application-Specific Case Studies and Solutions

- Making Informed Decisions on Aluminum Grating Price

(aluminum grating price)

The Current Market Overview of Aluminum Grating Price

Global aluminum grating price

s currently fluctuate between $18-$45 per square foot, influenced primarily by fluctuating aluminum ingot costs which constitute 60-70% of production expenses. Recent supply chain disruptions have increased lead times by 25% on average, while demand from wastewater treatment and offshore platforms continues to grow at 7% annually. Unlike stainless steel bar grating price structures that react sharply to nickel market volatility, or galvanised grating price which correlates directly with zinc coating thickness requirements, aluminum demonstrates greater long-term stability. Market intelligence suggests buyers can achieve 15% cost reductions through volume commitments exceeding 500 sq meters.

Technical Advantages Driving Material Selection

Aluminum grating outperforms alternatives in corrosion resistance, boasting a strength-to-weight ratio 3 times higher than galvanised steel while weighing approximately 50% less. This characteristic enables easier installation with 30% fewer support structures required. Unlike stainless steel bar grating which develops stress corrosion cracking in chloride-rich environments, aluminum naturally forms a protective oxide layer that maintains integrity even in marine applications. Additional benefits include:

- Electrical non-conductivity critical in power generation facilities

- Maintenance savings up to $18/sqft over 10-year lifecycles

- Non-sparking properties essential for chemical processing plants

- Recyclability rates exceeding 95% with no degradation

Comparative Pricing Analysis Across Materials

| Material | Thickness (mm) | Load Rating (kN/m²) | Price Range (USD/sqft) | Lifecycle Cost Index |

|---|---|---|---|---|

| Aluminum Grating | 30-50 | 3.0-5.0 | $18-$45 | 1.0 (Baseline) |

| Stainless Steel Bar Grating | 25-40 | 4.0-6.0 | $42-$85 | 1.8 |

| Galvanised Grating | 35-60 | 2.5-4.0 | $16-$38 | 2.2 |

Lifecycle costs incorporate installation, maintenance, replacement frequency and corrosion protection. While galvanised grating price appears initially attractive, hidden expenses include recoating every 5-7 years at $9-12/sqft. Stainless steel bar grating price premiums become justified only in extreme-temperature processing environments above 650°F.

Key Manufacturer Landscape and Value Analysis

Leading aluminum grating suppliers have developed distinct market specializations impacting aluminum grating price structures significantly:

- Nucor Grating: Optimized for high-volume industrial projects with prices 8-12% below market average for orders exceeding 2,000 sqft

- Ohio Gratings: Technical specialists in customized configurations with patented locking systems for seismic zones

- AMICO: Preferred by offshore operators with specialized marine-grade aluminum alloys

- Valley Grating: Economical standard sizes ideal for municipal applications

Third-party verification shows quality variances directly affect longevity. Premium manufacturers demonstrate 40% longer service life despite 8-15% higher initial aluminum grating price points.

Customization Variables Impacting Final Pricing

Standard aluminum grating price serves merely as a baseline, with engineering modifications creating cost multipliers:

- Surface Treatments: Non-skid embossing adds $4.50/sqft while anodizing increases cost by $7.20

- Load Specifications

- Fabrication Complexity: Curved profiles incur 30-60% cost premiums

- Finishes: Powder coating adds $3.80-6.25/sqft depending on RAL color complexity

- Special Alloys

For chemical processing plants, customized grating solutions integrating containment lips and chemical-resistant alloys typically command aluminum grating prices between $51-68/sqft but reduce maintenance downtime by up to 40%.

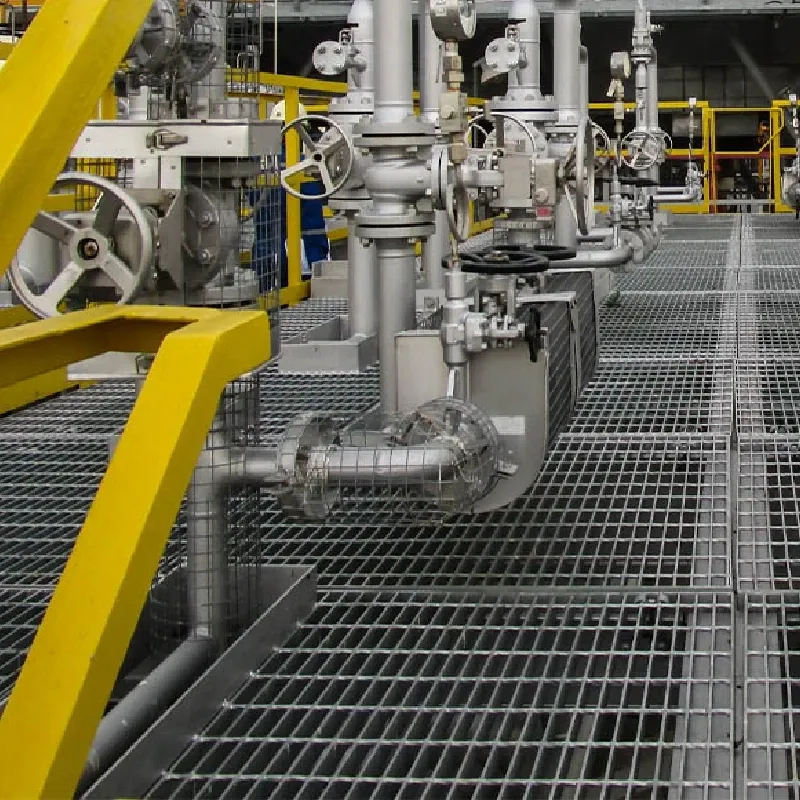

Application-Specific Case Studies and Solutions

Oil refinery in Texas achieved 22% lifecycle savings by selecting 6061-T6 aluminum grating instead of stainless steel for walkways despite 19% higher initial aluminum grating price. Calculations accounted for reduced structural support costs and elimination of bi-annual acid washing required for stainless steel bar grating.

Port authority installation demonstrated galvanised grating price underperformance in marine environments where corrosion necessitated complete replacement in 6 years, whereas aluminum grating showed minimal degradation after 11 years with only 13% cost premium initially. Offshore wind farm operators report aluminum walkways maintain structural integrity for 15+ years in salt spray zones.

Making Smart Choices for Your Aluminum Grating Price

Evaluating aluminum grating price requires multi-factorial analysis beyond initial purchase metrics. Industrial operators tracking total cost of ownership consistently identify aluminum as optimal for environments with moderate chemical exposure, temperature extremes between -80°F to 350°F, and applications requiring weight reduction. Critical purchasing considerations include:

- Requesting ASTM B221 certified mill test reports

- Validating slip resistance certifications (DIN 51130 R10 minimum)

- Comparing load-deflection test data for proposed configurations

Proactive aluminum grating price negotiation can secure volume discounts exceeding 17% for orders placed during off-peak manufacturing seasons. Leading contractors recommend obtaining lifecycle cost projections that factor in installation efficiencies, maintenance intervals, and replacement cycles rather than comparing base prices alone.

(aluminum grating price)

FAQS on aluminum grating price

What factors influence aluminum grating price?

Q: What determines the cost of aluminum grating?

A: Aluminum grating prices are primarily affected by material thickness, grid size, and finish specifications. Additional factors include quantity ordered and custom fabrication requirements.

How does stainless steel bar grating price compare to aluminum?

Q: Is stainless steel grating more expensive than aluminum grating?

A: Yes, stainless steel bar grating generally costs 20-50% more than aluminum options due to higher raw material expenses and manufacturing complexity. However, both remain cost-effective for corrosion-resistant applications.

What are galvanised grating price advantages?

Q: Why choose galvanised grating price-wise?

A: Galvanised grating offers the lowest initial cost among metal grating types. Its zinc coating provides corrosion resistance without premium alloy prices, making it economical for industrial use.

Can I get volume discounts on aluminum grating?

Q: Do suppliers offer bulk pricing for aluminum grating?

A: Yes, most manufacturers provide discounted aluminum grating pricing for large orders. Savings increase with higher quantities due to reduced production setup costs per unit.

How durable are these gratings relative to price?

Q: Does higher price mean better longevity?

A: While stainless steel offers maximum durability, aluminum grating provides exceptional corrosion resistance at lower prices. Galvanised options deliver good value where extreme corrosion isn't expected.

-

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025