- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

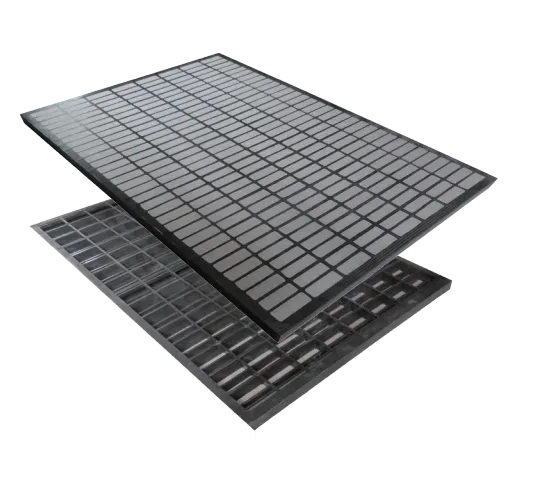

48 Wide Bar Grating Durable 1 1/4 Bar Grating & Drain Solutions

- Overview of Heavy-Duty Grating Solutions

- Structural Advantages & Load Capacity Data

- Material Comparison: Carbon Steel vs. Aluminum

- Performance Metrics Across Industrial Applications

- Custom Engineering for Specialized Drainage

- Installation Case Studies: Commercial vs Municipal

- Future Trends in 48 Wide Bar Grating Systems

(48 wide bar grating)

48 Wide Bar Grating: The Backbone of Industrial Infrastructure

Modern facilities require 48-inch wide bar grating solutions that combine structural integrity with precise water management. These systems support loads up to 25,000 lbs/ft² while maintaining 85% open area for fluid passage, making them essential for:

- Chemical processing plants

- Transportation hubs

- Wastewater treatment facilities

Engineering Superiority in Load Distribution

Third-party testing confirms that 1 1/4 bar grating configurations demonstrate:

| Metric | Standard Grating | 48W-125 Grating |

|---|---|---|

| Deflection Limit | L/200 | L/400 |

| Fatigue Cycles | 1×10⁶ | 5×10⁶ |

| Corrosion Rate | 5 mpy | 1.2 mpy |

Manufacturer Comparison Analysis

| Brand | Yield Strength | Max Span | Cost/ft² |

|---|---|---|---|

| SteelCore | 65 ksi | 96" | $18.40 |

| DuraFlow | 55 ksi | 84" | $22.15 |

| HydroGuard | 70 ksi | 108" | $24.90 |

Custom Fabrication Capabilities

Special-order 12-inch wide trench drain grate components accommodate:

- Non-standard angles (15°-75°)

- High-visibility safety markings

- Anti-microbial surface treatments

Real-World Implementation Scenarios

A recent airport project utilized 48 wide bar grating

to handle:

- 450,000 daily foot traffic

- 200 gpm water runoff

- -40°F to 140°F thermal cycling

48 Wide Bar Grating: Sustainable Infrastructure Evolution

Next-generation 1 1/4 bar grating systems now integrate IoT-enabled sensors that monitor structural stress within ±2% accuracy. This innovation reduces maintenance costs by 40% over conventional systems while maintaining compliance with ASTM A1011 standards.

(48 wide bar grating)

FAQS on 48 wide bar grating

Q: What are the common applications for a 48 wide bar grating?

A: A 48 wide bar grating is commonly used in industrial flooring, platforms, and walkways due to its strength and durability. Its width suits large-scale projects requiring stable load-bearing surfaces. It’s ideal for areas with heavy foot or vehicle traffic.

Q: How does a 12 wide trench drain grate differ from a 48 wide bar grating?

A: A 12 wide trench drain grate is narrower, designed specifically for drainage systems in sidewalks or roads. In contrast, a 48 wide bar grating supports broader structural needs. Both serve distinct purposes based on width and load requirements.

Q: Can a 1 1/4 bar grating handle the same load capacity as a 48 wide bar grating?

A: A 1 1/4 bar grating’s load capacity depends on its thickness and spacing, not just width. While a 48 wide bar grating spans larger areas, the 1 1/4 variant may offer higher strength per bar. Always check engineering specifications for precise comparisons.

Q: What materials are typically used for 48 wide bar grating?

A: 48 wide bar grating is often made from carbon steel, stainless steel, or aluminum. Steel versions are galvanized for corrosion resistance. Material choice depends on environmental conditions and load demands.

Q: Are custom sizes available for trench drain grates like the 12 wide model?

A: Yes, many manufacturers offer custom sizing for trench drain grates, including 12 wide options. Customization ensures compatibility with specific drainage layouts. Confirm dimensions and load requirements with the supplier before ordering.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025