- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

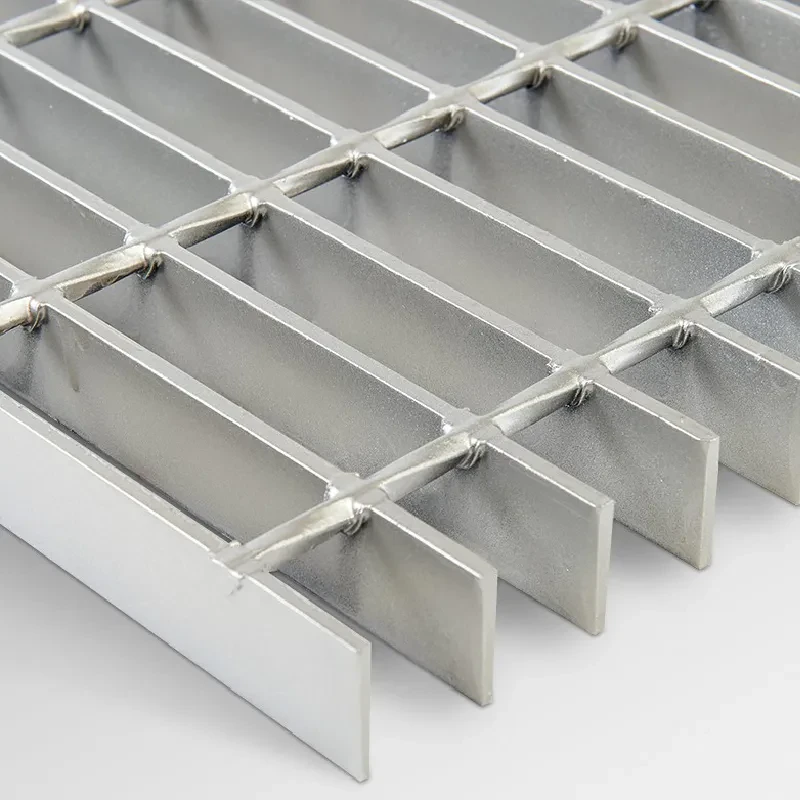

platform grating specification

Understanding Platform Grating Specification

In industrial and architectural applications, platform gratings play a crucial role in ensuring safety, accessibility, and operational efficiency. This article will delve into the critical aspects of platform grating specifications, focusing on materials, design, load capacity, safety standards, and maintenance.

1. Definition and Purpose

Platform gratings are perforated flooring systems used to provide walkways, decks, and platforms in various settings, including industrial sites, commercial buildings, and public infrastructures. Their primary purpose is to facilitate safe movement while allowing for airflow, drainage, and visibility to the underlying structure.

2. Materials Used

The choice of materials for platform gratings is paramount. Common materials include

- Steel Known for its strength and durability, steel gratings are often galvanised for enhanced corrosion resistance, making them ideal for outdoor and industrial applications. - Aluminum Lightweight and resistant to rust, aluminum gratings are beneficial in environments where weight is a concern, such as elevated platforms. - Fiberglass This non-metallic option is particularly advantageous for environments prone to corrosion and chemical exposure. Fiberglass gratings are also electrically non-conductive, making them safe for electrical applications.

The choice of material affects not only the grating’s longevity but also its weight load capacity and ease of installation.

3. Design Considerations

The design specifications of platform gratings can significantly influence safety and functionality

. Key considerations include- Open Area The percentage of open space within the grating affects light transmission and drainage. A higher open area increases safety in wet conditions, preventing slip hazards. - Bar Spacing The spacing between the supporting bars should be calculated to prevent small objects from falling through while still allowing for adequate drainage and airflow. - Thickness and Height The thickness of the grating affects its load-bearing capacity. Additionally, the height of the bars plays a role in the overall strength of the system.

platform grating specification

4. Load Capacity

One of the most critical aspects of platform grating specifications is its load capacity, which must align with the intended application. Load capacities are typically categorized into light, medium, and heavy-duty, which must be considered when selecting a grating type.

The load capacity is influenced by several factors, including

- Grating material Different materials provide various inherent strengths. - Support spacing The distance between supporting beams can impact how much weight the grating can bear. Closer support spacing generally allows for a higher load capacity. - Bar size and spacing Thicker bars and closer spacing typically result in greater load-bearing ability.

5. Safety Standards

Compliance with safety standards is essential in the production and installation of platform gratings. Standards such as those set by the American National Standards Institute (ANSI) or the Occupational Safety and Health Administration (OSHA) provide guidelines that enhance safety.

- Anti-slip surfaces To reduce the risk of accidents, gratings are often treated or designed with anti-slip features. - Edge treatments Safety typically requires rounded or beveled edges to prevent trip hazards, especially in high-traffic areas.

6. Maintenance and Inspection

Regular maintenance and inspection are vital for ensuring the longevity and safety of platform gratings. This includes checking for signs of wear, corrosion, or damage, especially in environments exposed to harsh conditions. Scheduled inspections can prevent accidents and costly repairs by addressing potential issues before they escalate.

Conclusion

In conclusion, platform grating specifications encompass various factors, including materials, design, load capacity, safety standards, and maintenance needs. By understanding these elements, engineers and architects can make informed decisions that not only meet operational requirements but also enhance safety and efficiency in their projects. Whether in industrial settings, commercial spaces, or public areas, the right choice of platform grating can significantly contribute to the overall functionality and safety of the environment.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025