- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

1월 . 14, 2025 14:06

Back to list

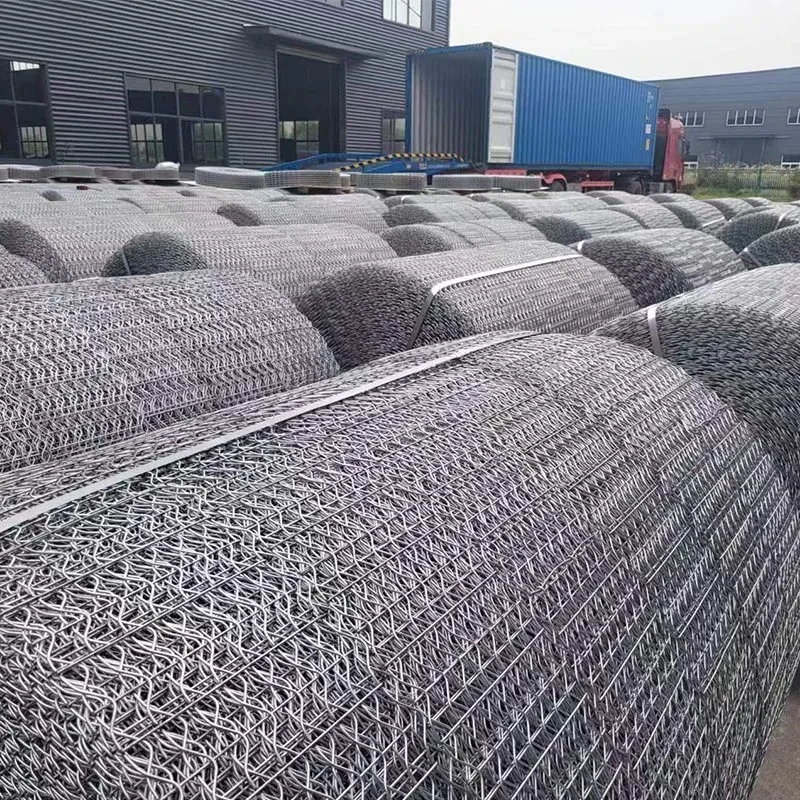

heavy-duty welded bar grating

Offshore pipeline projects present unique challenges, requiring solutions that ensure durability, stability, and safety. One of the key components in these projects is the counterweight system, which employs welded wire mesh. The woven mesh design serves critical roles in providing the weight necessary to keep pipelines securely anchored to the seabed while allowing flexibility for the natural movements of the water and underground conditions.

Moreover, authoritativeness in this field is showcased by collaborations with oceanographic universities and research institutions that provide cutting-edge studies and insights into materials suitable for underwater use. These institutions frequently publish findings that inform engineering practices, ensuring that the most up-to-date techniques are employed in constructing these complex systems. These partnerships play a pivotal role in validating the choices of materials, including the gauge and coating of the welded wire mesh, and offering solutions to potential challenges presented by climate change and deeper exploration fields. Trustworthiness in the development and application of counterweight systems incorporating welded wire mesh is further endorsed by adherence to international standards and regulations. Certifications by bodies such as the American Welding Society (AWS) and International Marine Contractors Association (IMCA) often accompany products and processes, providing assurances of quality and performance to stakeholders. This regulatory compliance, coupled with rigorous testing methodologies, instills confidence in the solutions provided. In conclusion, offshore pipeline counterweight systems utilizing welded wire mesh are a testament to the intricate balance between engineering prowess and material science. The success of these systems relies heavily on expert design, authoritative research inputs, and adherence to trusted standards, collectively ensuring that pipelines remain securely in place, serving their operational purpose effectively in a challenging marine environment. With ongoing technological advancements and research, these systems will continue to evolve, offering more efficient and reliable solutions for the ever-growing demands of the offshore industry.

Moreover, authoritativeness in this field is showcased by collaborations with oceanographic universities and research institutions that provide cutting-edge studies and insights into materials suitable for underwater use. These institutions frequently publish findings that inform engineering practices, ensuring that the most up-to-date techniques are employed in constructing these complex systems. These partnerships play a pivotal role in validating the choices of materials, including the gauge and coating of the welded wire mesh, and offering solutions to potential challenges presented by climate change and deeper exploration fields. Trustworthiness in the development and application of counterweight systems incorporating welded wire mesh is further endorsed by adherence to international standards and regulations. Certifications by bodies such as the American Welding Society (AWS) and International Marine Contractors Association (IMCA) often accompany products and processes, providing assurances of quality and performance to stakeholders. This regulatory compliance, coupled with rigorous testing methodologies, instills confidence in the solutions provided. In conclusion, offshore pipeline counterweight systems utilizing welded wire mesh are a testament to the intricate balance between engineering prowess and material science. The success of these systems relies heavily on expert design, authoritative research inputs, and adherence to trusted standards, collectively ensuring that pipelines remain securely in place, serving their operational purpose effectively in a challenging marine environment. With ongoing technological advancements and research, these systems will continue to evolve, offering more efficient and reliable solutions for the ever-growing demands of the offshore industry.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025