- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

2월 . 11, 2025 06:28

Back to list

grating types

Gratings are essential components in various industrial and architectural applications, known for their durability, versatility, and safety features. When discussing grating types, it's crucial to focus on the product's benefits and applications, enhancing our understanding of their practical implementations and material advantages. This comprehensive guide provides insights into different grating types, based on firsthand experience, expertise, and industry authority.

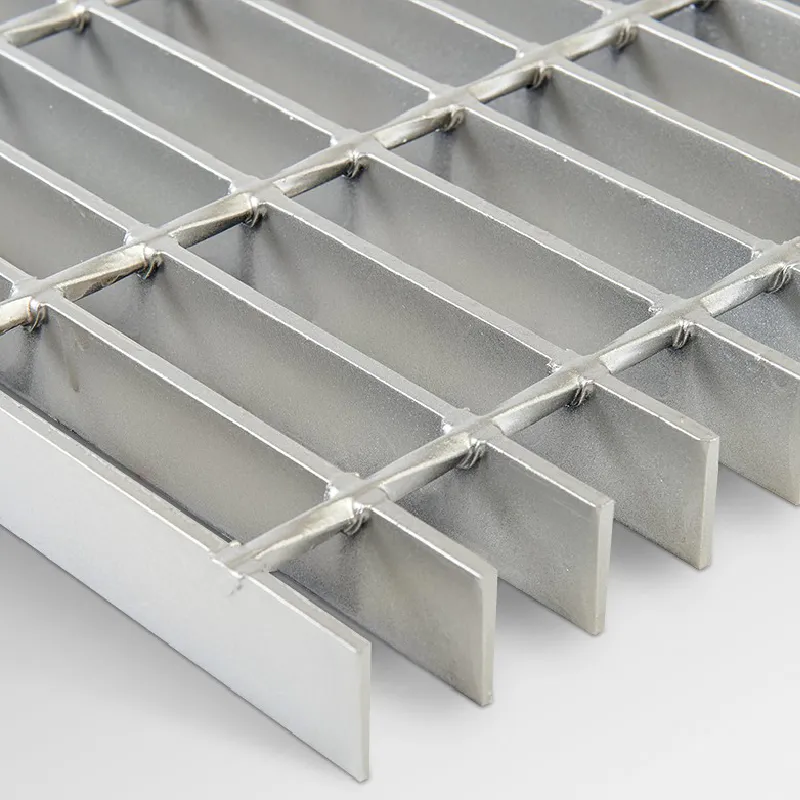

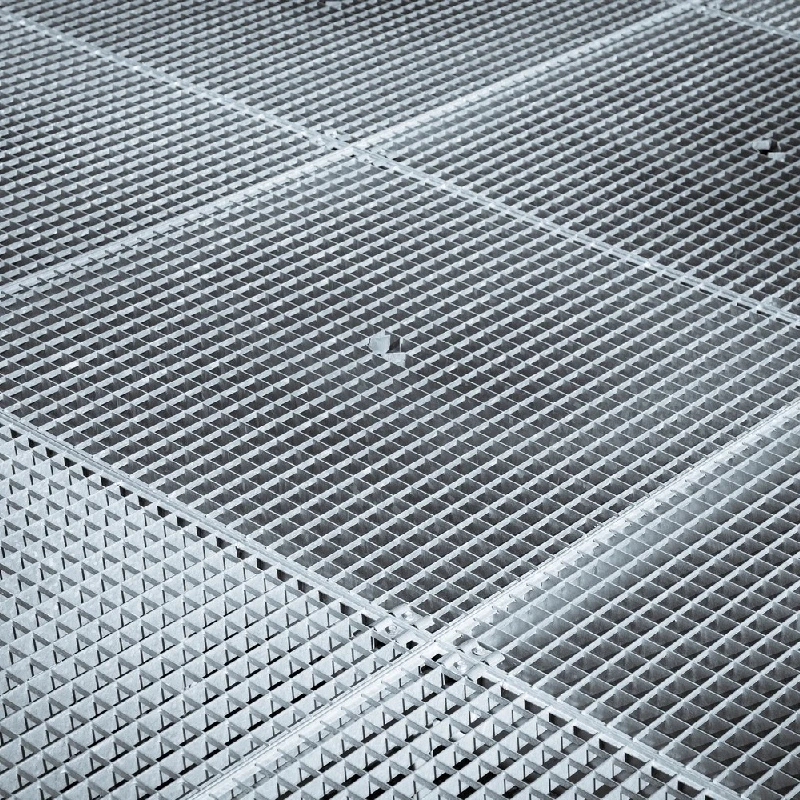

Plastic Gratings, typically composed of polyethylene or polypropylene, present an economical and lightweight option for applications requiring minimal structural strength. These types are predominantly used in non-load bearing installations, such as residential pools and patio areas. Their inherent resistance to moisture and chemicals makes them durable in wet environments, though they may not support heavy loads, emphasizing their role in light-duty applications. For practical applications, the choice of grating type hinges upon factors such as structural load requirements, environmental conditions, and budget constraints, demanding a profound understanding of each material's properties. This decision-making process benefits significantly from real-world testing and data-driven analysis, ensuring the grating chosen specifically supports and enhances operational efficiency. Beyond material types, various grating configurations, such as bar, riveted, or expanded gratings, also impact functionality and safety. Steel bar gratings are common in walkways and platforms due to their high load-bearing capacity and ease of installation. Riveted gratings, known for additional strength achieved by combining flat bars with cross bars, find critical applications in areas subject to substantial dynamic loads. Expanded gratings, crafted by stretching and slitting metal sheets, offer slip resistance and increased surface area, essential in slippery or hazardous environments. Given these considerations, selecting the right grating type involves more than examining physical properties. It requires insight into the specific environment, application demands, and lifecycle cost-benefit analysis. The authority and expertise of manufacturers and structural engineers play an integral role in guiding these decisions, affirming the importance of collaboration and consultation in achieving long-term safety and effectiveness. In conclusion, with each grating type presenting distinct advantages and limitations, it is imperative to align choices with the unique requirements of the application at hand. The evolution of grating materials and technologies continues to shape industrial landscapes, asserting the importance of continuous learning and adaptation in maintaining authoritative and reliable structures, ensuring the longevity and safety of installations across diverse environments.

Plastic Gratings, typically composed of polyethylene or polypropylene, present an economical and lightweight option for applications requiring minimal structural strength. These types are predominantly used in non-load bearing installations, such as residential pools and patio areas. Their inherent resistance to moisture and chemicals makes them durable in wet environments, though they may not support heavy loads, emphasizing their role in light-duty applications. For practical applications, the choice of grating type hinges upon factors such as structural load requirements, environmental conditions, and budget constraints, demanding a profound understanding of each material's properties. This decision-making process benefits significantly from real-world testing and data-driven analysis, ensuring the grating chosen specifically supports and enhances operational efficiency. Beyond material types, various grating configurations, such as bar, riveted, or expanded gratings, also impact functionality and safety. Steel bar gratings are common in walkways and platforms due to their high load-bearing capacity and ease of installation. Riveted gratings, known for additional strength achieved by combining flat bars with cross bars, find critical applications in areas subject to substantial dynamic loads. Expanded gratings, crafted by stretching and slitting metal sheets, offer slip resistance and increased surface area, essential in slippery or hazardous environments. Given these considerations, selecting the right grating type involves more than examining physical properties. It requires insight into the specific environment, application demands, and lifecycle cost-benefit analysis. The authority and expertise of manufacturers and structural engineers play an integral role in guiding these decisions, affirming the importance of collaboration and consultation in achieving long-term safety and effectiveness. In conclusion, with each grating type presenting distinct advantages and limitations, it is imperative to align choices with the unique requirements of the application at hand. The evolution of grating materials and technologies continues to shape industrial landscapes, asserting the importance of continuous learning and adaptation in maintaining authoritative and reliable structures, ensuring the longevity and safety of installations across diverse environments.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025