- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

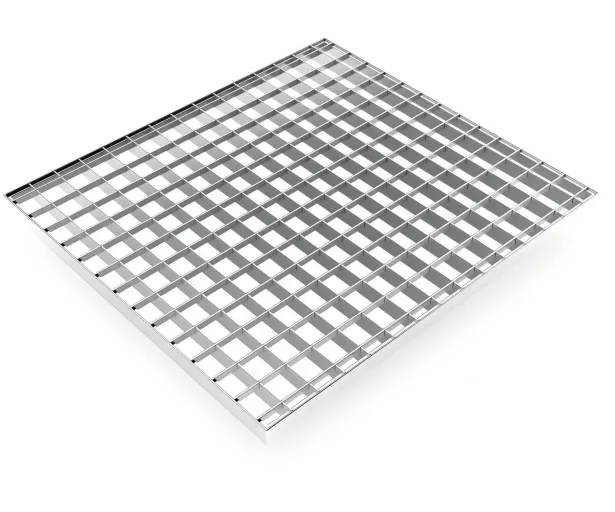

Comparative Analysis of Costs for Galvanized Grating Solutions in Today's Market

Understanding the Pricing of Galvanized Grating

Galvanized grating is an essential component in various industrial applications, providing a sturdy and durable solution for flooring, walkways, and platforms. Its resilience against environmental factors stems from a galvanization process, where steel grating is coated with zinc to prevent rust and corrosion. This protective layer not only extends the life of the grating but also makes it a cost-effective option for many projects. However, the pricing of galvanized grating can vary significantly based on several factors, including material quality, manufacturing processes, market demand, and customization options.

1. Material Quality and Type

The type of steel utilized in the production of galvanized grating plays a crucial role in determining its price. Galvanized grating typically comes in several forms, including bar grating, expanded metal grating, and woven wire grating. Bar grating, manufactured from high-quality carbon steel, is often more expensive than its expanded metal counterparts due to its strength and load-bearing capacity. Additionally, the thickness of the steel bars will also influence the price; thicker bars will generally lead to higher costs.

The manufacturing method used to create the galvanized grating impacts its price as well. For instance, the hot-dip galvanizing process involves immersing fabricated steel grating in molten zinc, resulting in a thick, protective coating. While this method provides superior corrosion resistance, it is also costlier compared to other processes like electro-galvanizing, which produces a thinner zinc layer. Manufacturers often charge more for hot-dip galvanized products, reflecting the higher material costs and energy consumption involved in the process.

galvanized grating price

3. Market Demand and Economic Factors

Like most commodities, the pricing of galvanized grating is subject to fluctuations dictated by market demand and broader economic conditions. Economic booms often result in increased construction and infrastructure projects, subsequently driving up demand for galvanized products. Conversely, during economic downturns, demand may decline, affecting pricing strategies. Additionally, global steel prices can fluctuate based on tariffs, trade policies, and raw material costs, all of which influence the prices of finished products, including galvanized grating.

4. Customization Options

Customization is another significant factor that can impact the price of galvanized grating. Many manufacturers offer a range of options tailored to meet specific project requirements, such as different sizes, load ratings, and surface treatments. Custom designs, such as non-slip surfaces or special coatings, will typically incur additional costs. While standard sizes are usually available at lower prices, customized products fulfill unique project specifications and may be worth the investment.

5. Conclusion

In conclusion, the price of galvanized grating is influenced by several intertwined factors, from material selection and manufacturing processes to market dynamics and customization options. When considering the purchase of galvanized grating, it is essential to evaluate the specific needs of your project and weigh them against the available options. While the initial investment might seem high, the long-term benefits of durability and low maintenance can ultimately lead to cost savings. Thus, understanding these elements will empower buyers to make informed decisions, ensuring that they receive both quality and value for their investment in galvanized grating.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025