- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

bar grating weights

Understanding Bar Grating Weights An Overview

Bar grating, a commonly used architectural and industrial material, is known for its durability, versatility, and load-bearing capacity. It comprises a series of parallel bars, typically made from steel, aluminum, or fiberglass, that are welded or mechanically fastened to a series of crossbars, forming a grid pattern. One critical aspect of bar grating that engineers and architects must consider during design and selection is the weight of the material. This article will explore the factors influencing bar grating weights, their implications, and how to select the appropriate type for various applications.

Factors Influencing Bar Grating Weight

Several factors dictate the overall weight of bar grating, including the material used, the bar thickness, and the spacing between the bars.

1. Material Type The most common materials for bar grating include steel, aluminum, and fiberglass. Steel grating, often hot-dipped galvanized for corrosion resistance, tends to be the heaviest due to its density. Aluminum grating offers a lightweight alternative while still providing excellent strength and support in various applications. Fiberglass reinforced plastic (FRP) grating is even lighter than aluminum, making it suitable for specialized applications where weight limitation is critical.

2. Bar Thickness The thickness of the individual bars plays a significant role in the overall weight of the grating. Thicker bars generally provide greater load-bearing capabilities but will also result in a heavier final product. Conversely, thinner bars reduce weight but may not support as much load, necessitating careful consideration of the intended application.

3. Bar Spacing The spacing between the bars also impacts weight. Wider spacing can reduce the amount of material used, thereby lowering the weight of the grating. However, this must be balanced against the desired level of support and safety for foot traffic or machinery.

bar grating weights

Implications of Bar Grating Weight

Understanding the weight of bar grating is essential for several reasons. First, it affects the overall design and structural integrity of the project. Engineers must ensure that the supporting structures, such as beams or frameworks, can accommodate the weight of the grating, particularly in larger installations.

Second, the weight has practical implications during transportation and installation. Heavier grating requires more robust lifting equipment and additional labor, leading to increased project costs and time. As a result, selecting a lightweight material can significantly streamline both logistics and installation processes.

Selecting the Appropriate Bar Grating

When choosing bar grating for a specific application, it is essential to consider the load requirements, environmental conditions, and installation constraints. For heavy industrial applications, steel may be the best choice due to its strength and resilience. In contrast, for pedestrian walkways or applications requiring corrosion resistance, aluminum or FRP grating might be more appropriate.

In conclusion, understanding the weights of bar grating is crucial for engineering and architectural design. By considering material types, bar thicknesses, and spacing, professionals can ensure that they select the right grating to balance weight, strength, and functionality for their project needs. Making an informed decision leads to enhanced safety, cost-effectiveness, and longevity of the installation.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

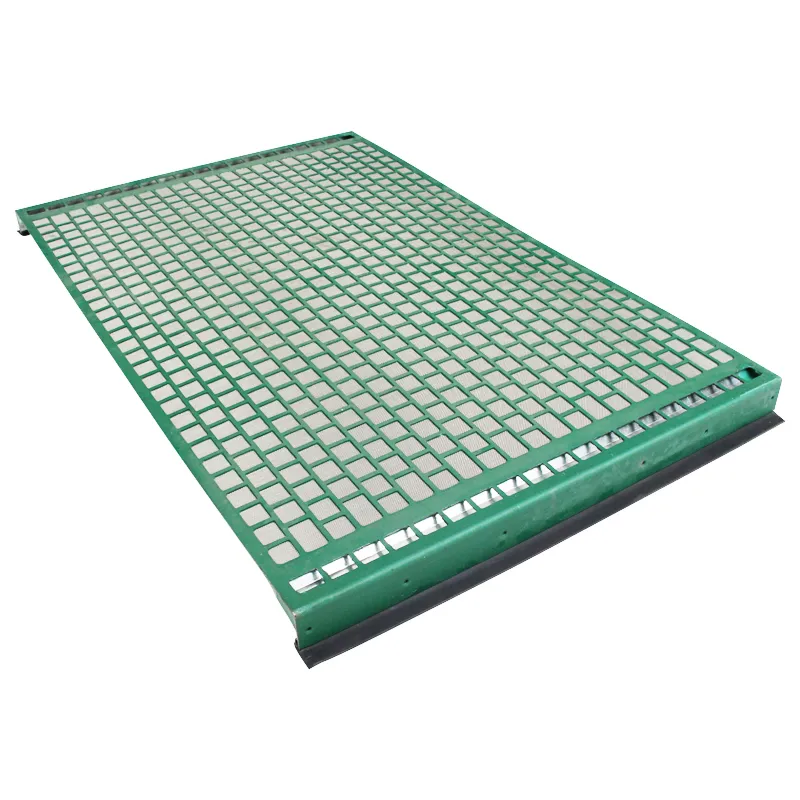

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025