- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Innovative Solutions for Durable Welded Bar Grating Applications in Industrial Settings

Understanding Welded Bar Grating Applications and Benefits

Welded bar grating is an essential component in various industrial applications, known for its strength, durability, and versatility. This type of grating is constructed by welding horizontal and vertical bars together at their intersections. The result is a robust and stable framework that can support heavy loads while providing excellent drainage and ventilation. In this article, we will explore the structure, applications, benefits, and considerations associated with welded bar grating.

Structure of Welded Bar Grating

Welded bar grating typically consists of two types of bars bearing bars and cross bars. The bearing bars are the primary load-bearing elements, while the cross bars are welded perpendicularly to provide additional support and stability. The spacing between the bars can vary according to specific requirements, allowing for customization based on load capacity and design needs. The grating can be made from various materials, including galvanized steel, stainless steel, and aluminum, each offering unique advantages depending on the environmental conditions in which they will be used.

Applications

Welded bar grating serves a multitude of purposes across various industries. Some of the most common applications include

1. Industrial Flooring Due to its high load-bearing capacity, welded bar grating is frequently used in factories and warehouses as flooring. Its open design allows for easy drainage and provides excellent traction, making it safer for workers.

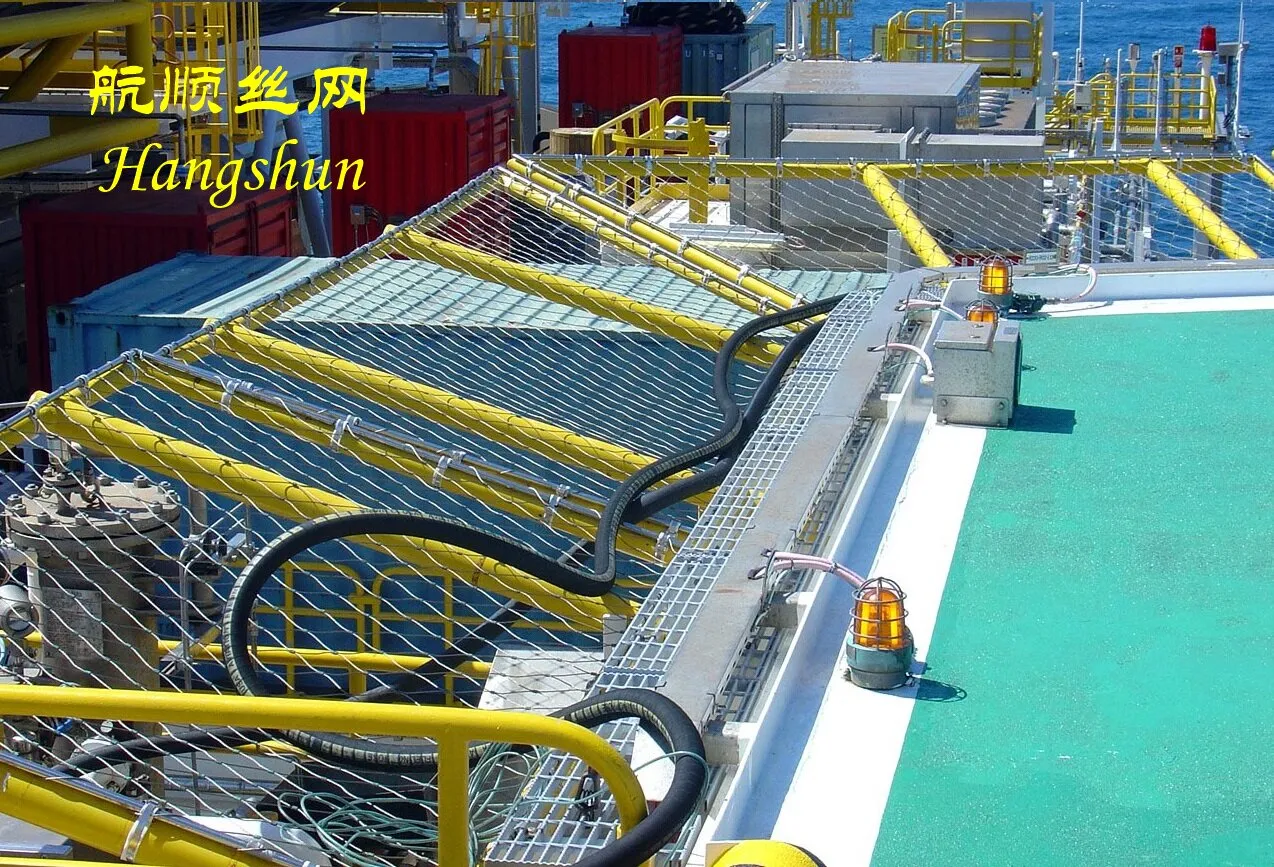

2. Platform and Walkway Construction This type of grating is ideal for constructing platforms and walkways in industrial settings. It helps to prevent the accumulation of water and debris, thereby reducing slip hazards.

3. Drainage Systems In many urban environments, welded bar grating is used in drainage systems to allow water to flow freely while preventing debris, leaves, and other materials from clogging the drainage channels.

4. Security Fencing The robust nature of welded bar grating makes it suitable for security fencing around industrial sites, ensuring that the area is both visible and secure.

5. Heavy Machinery Support Welded bar grating can be used as a base for heavy machinery, providing a stable and durable surface that can support significant weights.

6. Architectural Features Beyond its industrial uses, welded bar grating is also finding its way into contemporary architecture as a design element in flooring and facades.

Benefits

welded bar grating

Welded bar grating offers several advantages that make it a popular choice

- Strength and Durability The welding process creates a strong bond between the bars, resulting in a grating that can withstand high loads and resist deformation over time.

- Low Maintenance Compared to other materials, welded bar grating requires minimal maintenance. Its open design prevents the accumulation of dirt and debris, which minimizes cleaning efforts.

- Versatility The ability to customize the spacing and sizes of the bars allows welded bar grating to be tailored for a wide range of applications, making it suitable for various industries.

- Cost-Effectiveness When considering its longevity and minimal maintenance needs, welded bar grating is a cost-effective solution in the long run.

- Safety With its slip-resistant surface, welded bar grating enhances workplace safety by reducing the risk of slips and falls.

Considerations

While there are many benefits to using welded bar grating, there are also considerations to keep in mind

- Weight Depending on the application, the weight of the grating can be a factor. In applications where weight is a concern, options like aluminum may be preferred over steel.

- Corrosion Resistance Depending on the environment, coatings or materials that offer corrosion resistance may be necessary. For instance, stainless steel is often used in environments with high moisture or exposure to chemicals.

- Installation Proper installation is critical to ensure the safety and effectiveness of welded bar grating. It’s essential to follow manufacturer guidelines and industry standards during the installation process.

In conclusion, welded bar grating is a versatile and robust solution suitable for a wide range of industrial and architectural applications. Its strength, low maintenance, and safety features make it an attractive option for many sectors. As industries continue to evolve, welded bar grating will undoubtedly remain a critical component in creating safe and functional environments.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025