- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Optimizing Derrick Shaker Screens for Enhanced Performance in Oil and Gas Drilling Operations

Derrick Shaker Screens Enhancing Efficiency in Drilling Operations

In the oil and gas industry, the efficiency of drilling operations is paramount. One of the critical components that contribute to this efficiency is the shaker screen, a vital element in the separation of drilling fluids from cuttings. Among the leading manufacturers of shaker screens is Derrick Equipment Company, renowned for its innovation and high-quality products.

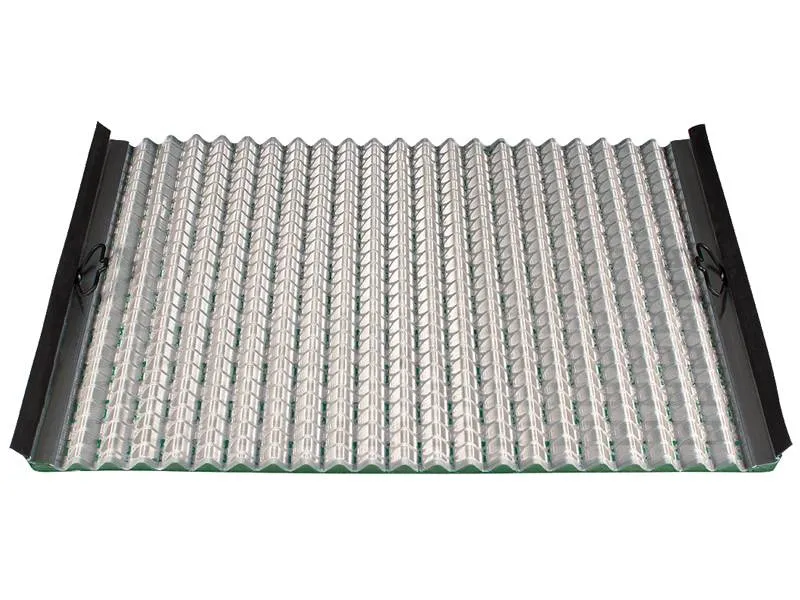

Derrick shaker screens are designed to withstand the rigorous demands of oil and gas drilling, as well as other industries such as mining and civil construction. These screens play a crucial role in the drilling process by filtering out rock cuttings and other solid materials from the drilling fluid, also known as mud. This separation is essential for maintaining the desired properties of the fluid, which in turn affects the overall efficiency of the drilling operation.

Derrick Shaker Screens Enhancing Efficiency in Drilling Operations

Additionally, Derrick shaker screens are equipped with high-capacity openings that facilitate maximum flow rate while maintaining effective particle separation. The innovative design allows for various mesh configurations, enabling operators to tailor the screening process to their specific needs. This versatility is particularly beneficial in operations where different types of drilling fluids and materials are encountered, ensuring optimal performance across varying conditions.

derrick shaker screens

Another key feature of Derrick screens is their compatibility with the latest advancements in drilling technology. As the industry shifts towards automated and more efficient drilling practices, Derrick has continuously adapted its products to meet these changing requirements. For instance, their screens can easily integrate with modern shaker systems and are designed to enhance the overall performance of these systems. This integration is critical in maximizing the effectiveness of the entire drilling setup, thereby improving productivity.

Moreover, Derrick Equipment Company places a significant emphasis on sustainability. The durability and efficiency of their shaker screens contribute to a reduced environmental footprint for drilling operations. By minimizing waste and ensuring that drilling fluids are effectively recycled, Derrick screens help operators adhere to stringent environmental regulations while promoting best practices in resource management.

In terms of maintenance, Derrick shaker screens are designed for easy installation and replacement, minimizing downtime during operations. The company provides comprehensive support and guidance to ensure that operators can maximize the lifespan and efficiency of the screens. This level of support is essential for maintaining seamless drilling operations, particularly in remote and challenging environments.

In conclusion, Derrick shaker screens are a vital component of modern drilling operations, offering an array of benefits that enhance efficiency and reduce operational costs. Through their innovative designs, high durability, compatibility with advanced technologies, and commitment to sustainability, Derrick has established itself as a leader in the industry. For operators seeking to optimize their drilling processes, investing in Derrick shaker screens represents a strategic decision that can lead to significant improvements in productivity and operational excellence.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025