- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ಜನ . 19, 2025 05:40

Back to list

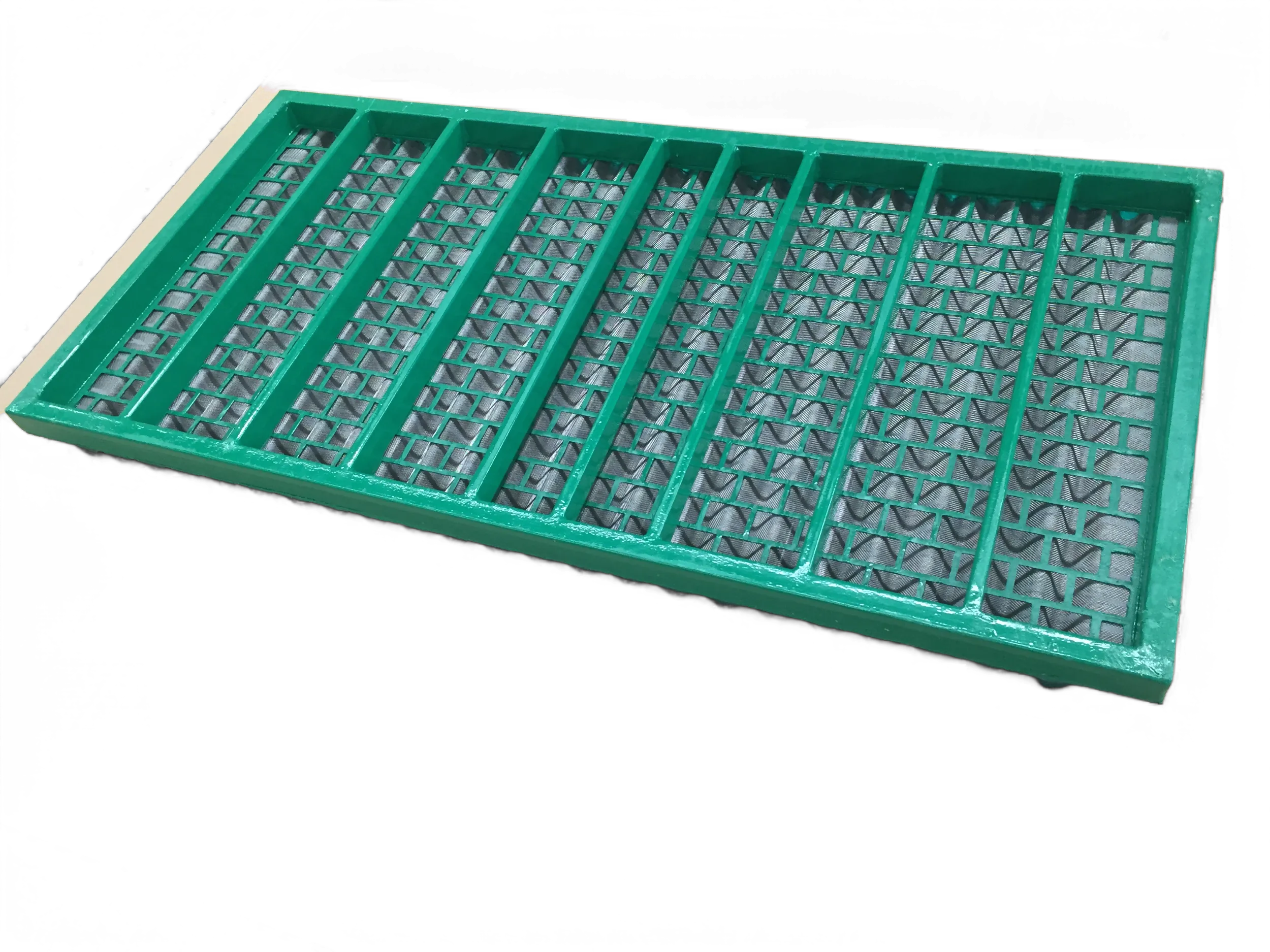

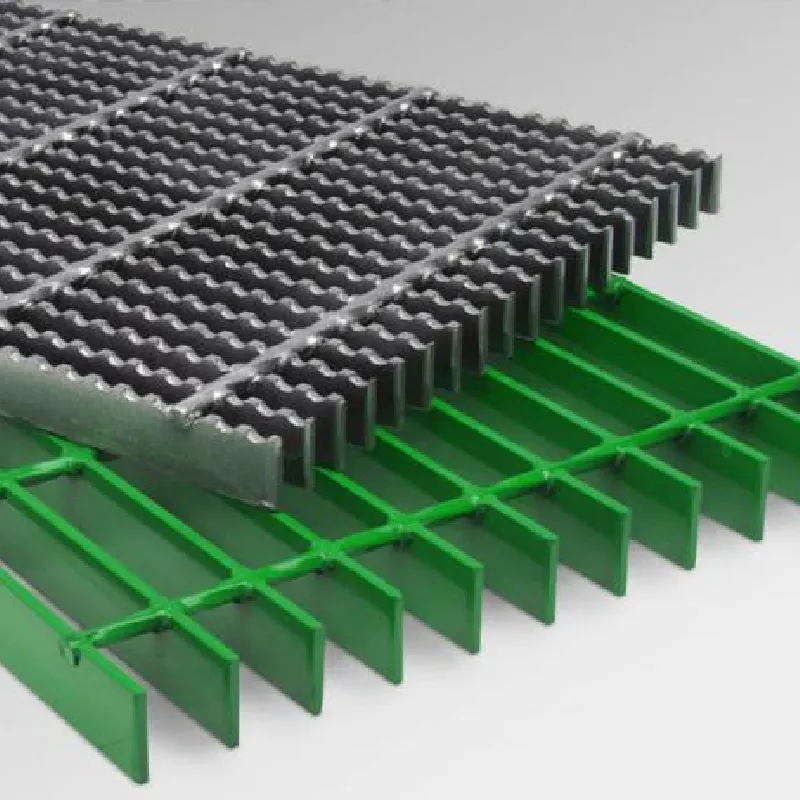

Steel Grating

Galvanised iron grating is a product that stands out in the construction industry, celebrated for its durability, reliability, and cost-effectiveness. For those looking to integrate this versatile material into their projects, understanding its material properties, applications, and benefits is crucial. Having worked extensively with galvanized iron grating products, I bring insights from personal experience and professional expertise to give you a comprehensive overview of this phenomenal material.

Trustworthiness is another contributing factor to the favored status of galvanized iron grating. Numerous standards and certifications govern these products, guiding their production to meet strict safety and quality benchmarks. Buyers should always verify compliance with pertinent industry standards, such as AS/NZS 4680 (Australia/New Zealand standard for hot-dip galvanized coatings) or ASTM A123/A123M (American standard specification for zinc coatings), ensuring that what they procure is safe, reliable, and in conformance with internationally recognized guidelines. The economic benefits of choosing galvanized iron grating cannot be overstated. Although the initial cost may be slightly higher than non-galvanized options, the return on investment becomes clear over time. Lower maintenance requirements, prolonged service life, and enhanced structural integrity contribute to a reduction in both short-term and long-term costs. When weighed against alternative materials, the cost-effectiveness of galvanized iron grating, particularly in high-demand environments, makes it a prudent investment. Having had first-hand experience in projects utilizing galvanized iron grating, I can assert its importance in both practical and economic terms. Whether outfitting a new facility or retrofitting an existing one, the decision to use galvanized iron grating translates to peace of mind, given its track record of performance and dependability. Engaging with a knowledgeable supplier ensures the selection process is streamlined, and that the grating will serve its purpose effectively across the intended lifespan. For industries ranging from construction and architecture to manufacturing and public services, galvanized iron grating offers a blend of robustness, reliability, and return on investment that few materials can match. It is a product that not only meets the demands of modern engineering and design but exceeds expectations in longevity and performance. In summary, the merits of galvanized iron grating are multiple, positioning it as a material that deserves consideration in any project scope where durability and safety are non-negotiable.

Trustworthiness is another contributing factor to the favored status of galvanized iron grating. Numerous standards and certifications govern these products, guiding their production to meet strict safety and quality benchmarks. Buyers should always verify compliance with pertinent industry standards, such as AS/NZS 4680 (Australia/New Zealand standard for hot-dip galvanized coatings) or ASTM A123/A123M (American standard specification for zinc coatings), ensuring that what they procure is safe, reliable, and in conformance with internationally recognized guidelines. The economic benefits of choosing galvanized iron grating cannot be overstated. Although the initial cost may be slightly higher than non-galvanized options, the return on investment becomes clear over time. Lower maintenance requirements, prolonged service life, and enhanced structural integrity contribute to a reduction in both short-term and long-term costs. When weighed against alternative materials, the cost-effectiveness of galvanized iron grating, particularly in high-demand environments, makes it a prudent investment. Having had first-hand experience in projects utilizing galvanized iron grating, I can assert its importance in both practical and economic terms. Whether outfitting a new facility or retrofitting an existing one, the decision to use galvanized iron grating translates to peace of mind, given its track record of performance and dependability. Engaging with a knowledgeable supplier ensures the selection process is streamlined, and that the grating will serve its purpose effectively across the intended lifespan. For industries ranging from construction and architecture to manufacturing and public services, galvanized iron grating offers a blend of robustness, reliability, and return on investment that few materials can match. It is a product that not only meets the demands of modern engineering and design but exceeds expectations in longevity and performance. In summary, the merits of galvanized iron grating are multiple, positioning it as a material that deserves consideration in any project scope where durability and safety are non-negotiable.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025