- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ಫೆಬ್ರ . 15, 2025 10:03

Back to list

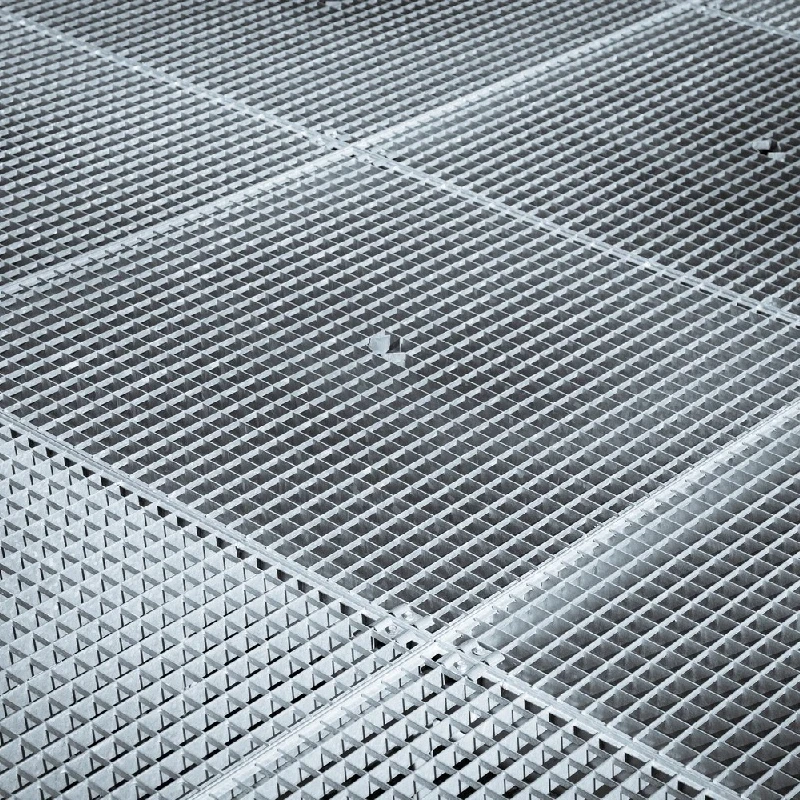

bar grating steps

Bar grating steps are an essential component in various industrial and commercial applications. Known for their strength, durability, and versatility, these metal structures offer a range of benefits crucial for safety and efficiency. This article provides an in-depth exploration of bar grating steps, drawing from expert insights, real-world applications, and authoritative sources to establish their essential role in multiple sectors.

Real-world applications highlight the indispensable nature of bar grating steps. In oil and gas facilities, they provide safe access for workers to equipment and critical areas while withstanding the rigorous demands of the environment. In public infrastructures like bridges and walkways, they ensure pedestrian safety without obstructing natural light or views. Even in commercial spaces such as retail and office buildings, bar grating steps contribute to aesthetic appeal with their sleek industrial look while maintaining functionality and safety. Authoritative sources like OSHA (Occupational Safety and Health Administration) emphasize the importance of compliant and well-maintained access structures. Bar grating steps align with these regulatory requirements by offering predictable performance and reliability. Users can trust these structures to deliver consistent quality and safety, vital in environments where these criteria cannot be compromised. Moreover, bar grating manufacturers are continually innovating to enhance product offerings. Advances in fabrication technology and materials science are leading to stronger, lighter, and more environmentally friendly grating solutions. These developments not only improve performance but also contribute to sustainable building practices, an increasingly important consideration in contemporary construction and design. In conclusion, bar grating steps offer unparalleled utility across industries, backed by their robust construction, customizable features, and safety benefits. Their critical role in maintaining workplace safety and operational efficiency underscores their widespread adoption and continued popularity. By choosing bar grating steps, businesses and facilities not only comply with safety standards but also invest in long-term reliability and performance.

Real-world applications highlight the indispensable nature of bar grating steps. In oil and gas facilities, they provide safe access for workers to equipment and critical areas while withstanding the rigorous demands of the environment. In public infrastructures like bridges and walkways, they ensure pedestrian safety without obstructing natural light or views. Even in commercial spaces such as retail and office buildings, bar grating steps contribute to aesthetic appeal with their sleek industrial look while maintaining functionality and safety. Authoritative sources like OSHA (Occupational Safety and Health Administration) emphasize the importance of compliant and well-maintained access structures. Bar grating steps align with these regulatory requirements by offering predictable performance and reliability. Users can trust these structures to deliver consistent quality and safety, vital in environments where these criteria cannot be compromised. Moreover, bar grating manufacturers are continually innovating to enhance product offerings. Advances in fabrication technology and materials science are leading to stronger, lighter, and more environmentally friendly grating solutions. These developments not only improve performance but also contribute to sustainable building practices, an increasingly important consideration in contemporary construction and design. In conclusion, bar grating steps offer unparalleled utility across industries, backed by their robust construction, customizable features, and safety benefits. Their critical role in maintaining workplace safety and operational efficiency underscores their widespread adoption and continued popularity. By choosing bar grating steps, businesses and facilities not only comply with safety standards but also invest in long-term reliability and performance.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025