- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កុម្ភៈ . 20, 2025 12:52

Back to list

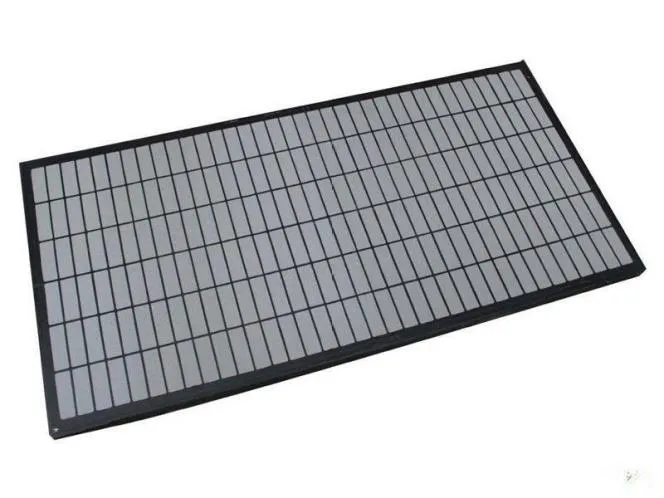

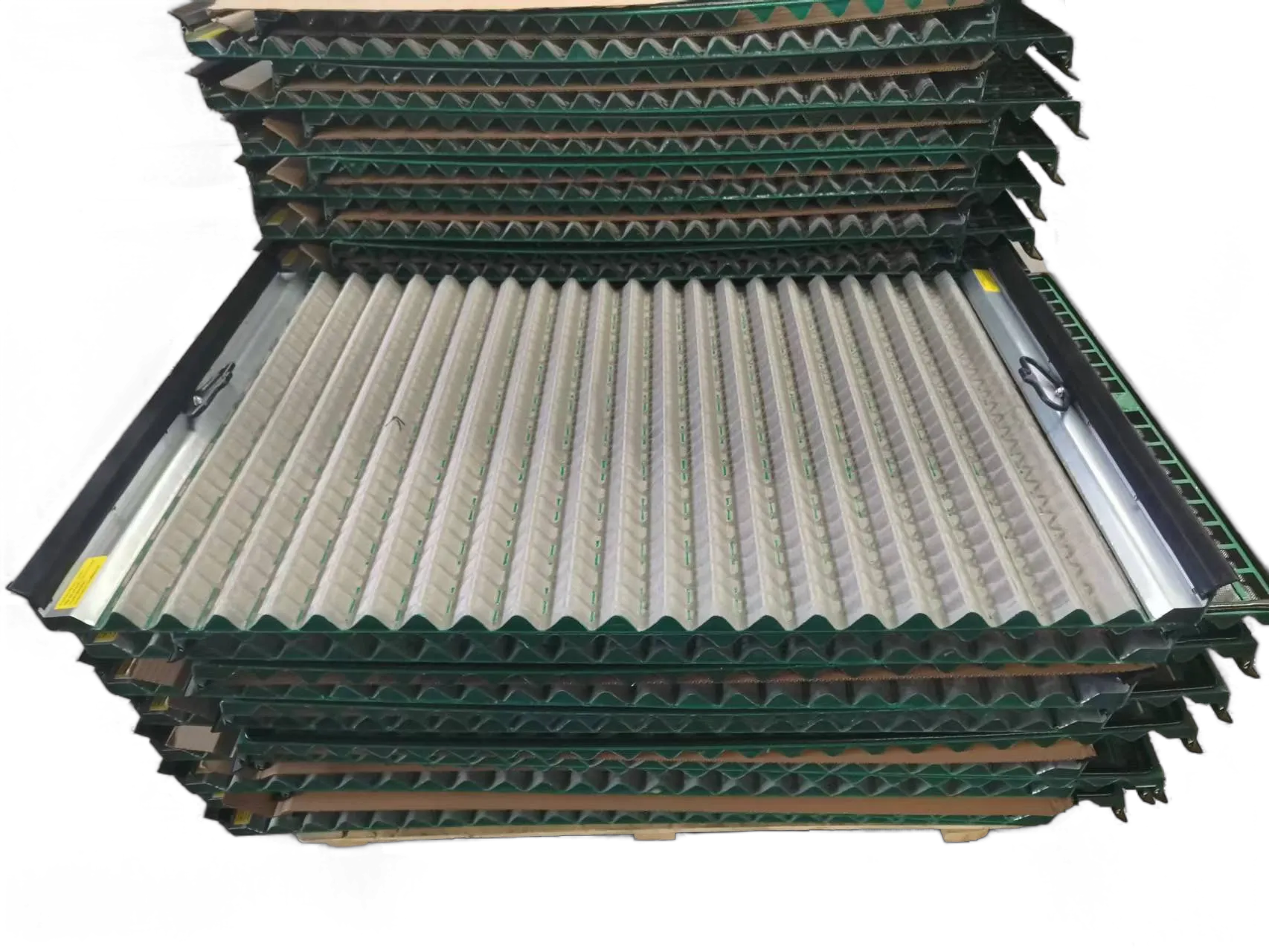

Composite Frame Shaker Screen

In the complex and demanding realm of oilfield operations, the efficiency and effectiveness of equipment can significantly influence productivity and cost management. Among the plethora of essential drilling tools, SWACO shaker screens stand out as a pivotal component, ensuring the seamless separation of solids from drilling fluids. This article delves into the intricacies of SWACO shaker screens, highlighting their critical role, design innovations, and their impact on the oil and gas industry.

The environmental impact is a major consideration in modern oilfield operations, and SWACO shaker screens contribute significantly to sustainable practices. By efficiently separating solids from drilling fluids, these screens minimize waste and support the recycling and reuse of drilling fluids. This capability not only reduces the environmental footprint of drilling activities but also leads to substantial cost savings. Operators can lower their expenses associated with waste management and the procurement of new drilling fluids, thereby enhancing the overall economic efficiency of their operations. Furthermore, the ease of maintenance associated with SWACO shaker screens adds to their appeal. The screens are designed for quick and easy replacement, minimizing downtime and maximizing operational continuity. This ease of maintenance is especially beneficial in remote locations where operational efficiency is paramount and any delay can translate to significant financial implications. The widespread adoption of SWACO shaker screens across the global oil and gas industry is a testament to their effectiveness and reliability. Companies that have integrated these shaker screens into their drilling operations report improved operational efficiency, reduced environmental impact, and enhanced cost-effectiveness. Testimonials from industry experts consistently highlight the robust performance and adaptability of these screens across various drilling environments. In conclusion, SWACO shaker screens exemplify the convergence of innovative engineering and reliable performance in the oil and gas sector. Their ability to enhance drilling efficiency while promoting sustainable practices makes them an indispensable asset in modern drilling operations. By investing in SWACO shaker screens, companies can achieve significant operational enhancements, ultimately leading to a more sustainable and profitable future in the energy industry.

The environmental impact is a major consideration in modern oilfield operations, and SWACO shaker screens contribute significantly to sustainable practices. By efficiently separating solids from drilling fluids, these screens minimize waste and support the recycling and reuse of drilling fluids. This capability not only reduces the environmental footprint of drilling activities but also leads to substantial cost savings. Operators can lower their expenses associated with waste management and the procurement of new drilling fluids, thereby enhancing the overall economic efficiency of their operations. Furthermore, the ease of maintenance associated with SWACO shaker screens adds to their appeal. The screens are designed for quick and easy replacement, minimizing downtime and maximizing operational continuity. This ease of maintenance is especially beneficial in remote locations where operational efficiency is paramount and any delay can translate to significant financial implications. The widespread adoption of SWACO shaker screens across the global oil and gas industry is a testament to their effectiveness and reliability. Companies that have integrated these shaker screens into their drilling operations report improved operational efficiency, reduced environmental impact, and enhanced cost-effectiveness. Testimonials from industry experts consistently highlight the robust performance and adaptability of these screens across various drilling environments. In conclusion, SWACO shaker screens exemplify the convergence of innovative engineering and reliable performance in the oil and gas sector. Their ability to enhance drilling efficiency while promoting sustainable practices makes them an indispensable asset in modern drilling operations. By investing in SWACO shaker screens, companies can achieve significant operational enhancements, ultimately leading to a more sustainable and profitable future in the energy industry.

Share

Prev:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025