- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Choosing the Right Material for Steel Grating Applications and Benefits

Steel Grating Material An Overview of Its Applications and Benefits

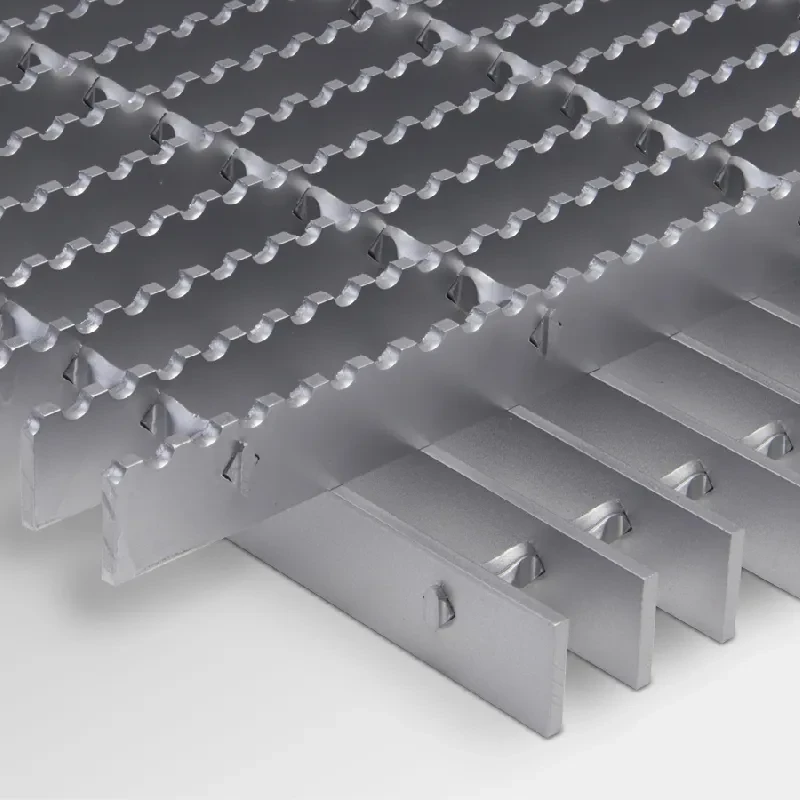

Steel grating is an essential material used in a variety of industries due to its strength, durability, and versatility. Comprising of a series of parallel bars or slats, steel grating is commonly employed in flooring, walkways, platforms, and other applications where a strong yet lightweight solution is required. This article delves into the characteristics, types, and applications of steel grating, as well as the benefits it offers compared to other materials.

Characteristics of Steel Grating

Steel grating is primarily made from carbon steel, stainless steel, or aluminum, depending on the specific application requirements. The primary features that make steel grating an attractive choice are its high load-bearing capacity, corrosion resistance (especially with stainless steel), and long lifespan. Furthermore, steel grating is designed to provide excellent drainage and ventilation, as the open grid structure allows water and air to flow freely, reducing the likelihood of slip hazards in wet environments.

The fabrication of steel grating involves a process known as welding, where the intersecting bars are fused together at each joint. This creates a robust and stable platform that can bear significant weight without deforming. The spacing and sizing of the bars can be customized to meet particular needs, ranging from light-duty applications to heavy-duty industrial requirements.

Types of Steel Grating

There are several types of steel grating available in the market, each suited for different applications

1. Heavy-Duty Grating This type is ideal for areas with high foot and vehicle traffic. The thick bars can withstand intense loads and are often used in industrial settings such as power plants, factories, and construction sites.

2. Light-Duty Grating Used primarily for pedestrian walkways, this grating is lighter and designed for less demanding applications, such as commercial buildings and public spaces.

3. Safety Grating This variant often features a serrated or slip-resistant finish that improves traction, making it suitable for areas prone to spills or where high foot traffic is common.

4. Electrical Grating Specifically designed to accommodate electrical applications, this grating can provide easy access to electrical installations while ensuring safety.

5. Architectural Grating Used in aesthetic applications, this type combines functionality with decorative elements and is often found in commercial and public buildings.

Applications of Steel Grating

steel grating material

The versatility of steel grating allows it to be used across various sectors, such as

- Manufacturing Steel grating provides reliable flooring for warehouses and production facilities, allowing for safe movement of personnel and equipment.

- Transportation In transportation hubs like airports and train stations, steel grating is utilized for walkways, ensuring safety and durability amidst heavy foot traffic.

- Wastewater Treatment Steel grating is often found in health and environmental systems, where its drainage capabilities help manage flow and prevent debris accumulation.

- Oil & Gas Industry The robustness and chemical resistance of stainless steel grating make it a popular choice in oil refineries and offshore platforms, minimizing corrosion risks while maintaining structural integrity.

Benefits of Steel Grating

The use of steel grating comes with various advantages

- Strength and Durability Steel grating can withstand harsh environmental conditions, heavy loads, and significant wear and tear, resulting in a long-lasting solution.

- Cost-Effective While the initial investment may be higher than other materials, the longevity and low maintenance of steel grating translate into cost savings over time.

- Safety Features With its slip-resistant options and open design, steel grating enhances workplace safety by minimizing the risk of slipping and falls.

- Eco-Friendly Many steel gratings are made from recycled materials and can be fully recycled at the end of their lifespan, contributing to sustainability efforts in construction.

In conclusion, steel grating is a highly functional and practical material suitable for a wide array of applications across various industries. Its strength, versatility, and safety features make it an indispensable choice for engineers and architects alike. As industries continue to evolve, steel grating will undoubtedly play an essential role in providing innovative solutions that balance both durability and safety.

-

The Essential Tool for Drilling and Filtration SystemsNewsMay.07,2025

-

Steel Grating Company: The Best Choice for Industrial SolutionsNewsMay.07,2025

-

Shale Shaker Screens: The Key to Efficient Drilling OperationsNewsMay.07,2025

-

0Perimeter Safety Netting: Essential for Workplace SafetyNewsMay.07,2025

-

Helideck Safety Net: Essential Protection for Offshore PlatformsNewsMay.07,2025

-

Choosing the Right Steel Grating for Your NeedsNewsMay.07,2025