- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កុម្ភៈ . 18, 2025 05:10

Back to list

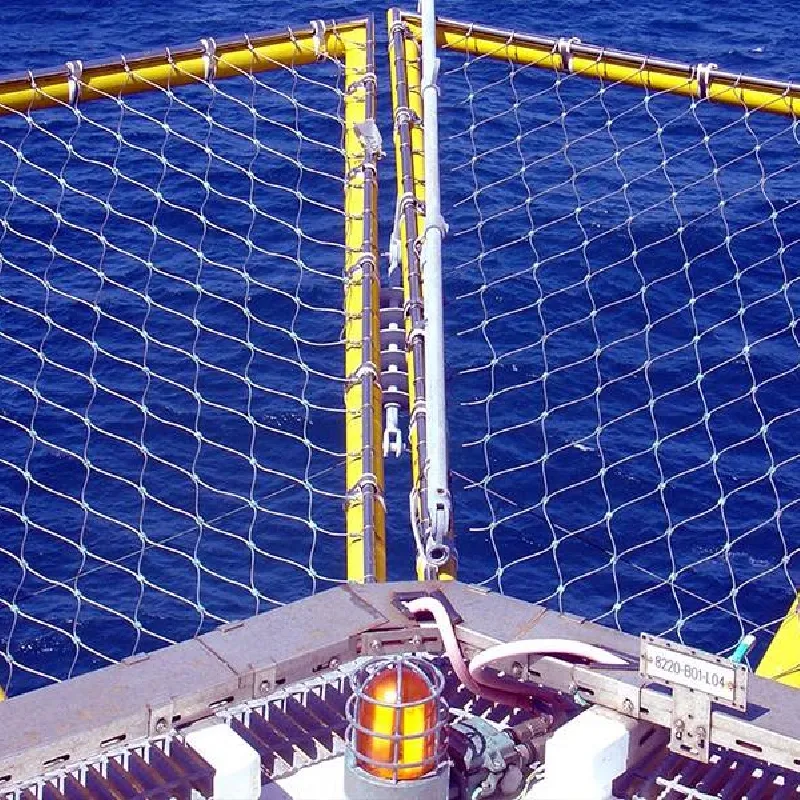

steel grating heavy duty

Steel grating heavy duty products have become indispensable in industries seeking reliable, durable solutions for flooring, catwalks, and service platforms. These gratings are known for their exceptional load-bearing capacity, making them the ideal choice for heavy industrial environments. With their robust design, they not only ensure safety but also enhance operational efficiency.

Trustworthiness in steel grating heavy duty applications is established through certification and standards compliance. High-quality gratings adhere to international standards, such as ISO, ASTM, or EN. These certifications are a testament to the product's credibility, ensuring that they meet all required safety and performance benchmarks. Clients can trust that certified gratings have undergone stringent testing, providing peace of mind when these products are employed in critical infrastructure projects. To maximize the benefits of using heavy-duty steel grating, it is essential to consider additional factors such as the installation process and maintenance practices. Proper installation by experienced professionals reduces the risk of future issues, while regular maintenance extends the lifespan of the grating, ensuring continuous performance. The trust earned from investing in well-manufactured, correctly installed, and carefully maintained steel grating spurs positive endorsements from engineers and safety inspectors alike. In conclusion, heavy-duty steel grating proves invaluable to industrial sectors requiring strong, dependable infrastructure solutions. Through experience, expertise, authoritative design, and trustworthiness, it remains a preferred choice for high-stress environments. Companies looking to optimize their operational capacities would do well to consider investing in this essential component, ensuring safety and efficiency in their facilities.

Trustworthiness in steel grating heavy duty applications is established through certification and standards compliance. High-quality gratings adhere to international standards, such as ISO, ASTM, or EN. These certifications are a testament to the product's credibility, ensuring that they meet all required safety and performance benchmarks. Clients can trust that certified gratings have undergone stringent testing, providing peace of mind when these products are employed in critical infrastructure projects. To maximize the benefits of using heavy-duty steel grating, it is essential to consider additional factors such as the installation process and maintenance practices. Proper installation by experienced professionals reduces the risk of future issues, while regular maintenance extends the lifespan of the grating, ensuring continuous performance. The trust earned from investing in well-manufactured, correctly installed, and carefully maintained steel grating spurs positive endorsements from engineers and safety inspectors alike. In conclusion, heavy-duty steel grating proves invaluable to industrial sectors requiring strong, dependable infrastructure solutions. Through experience, expertise, authoritative design, and trustworthiness, it remains a preferred choice for high-stress environments. Companies looking to optimize their operational capacities would do well to consider investing in this essential component, ensuring safety and efficiency in their facilities.

Share

Prev:

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025