- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

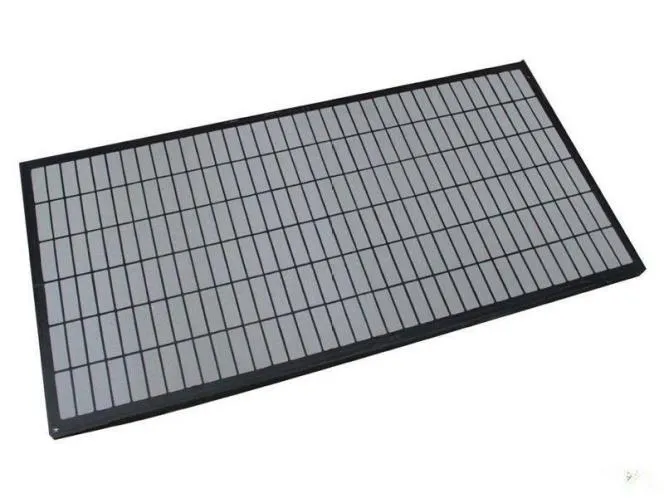

steel grating heavy duty

The Benefits and Applications of Heavy-Duty Steel Grating

Steel grating has become a popular choice in various industries due to its strength, durability, and versatility. Among its various types, heavy-duty steel grating stands out for its ability to support substantial loads while maintaining structural integrity. This article will explore the benefits and applications of heavy-duty steel grating, making it an essential material in modern construction and industrial settings.

What is Heavy-Duty Steel Grating?

Heavy-duty steel grating is a type of flooring made from steel bars, welded together in a grid pattern. Unlike standard grating, which is suitable for lighter applications, heavy-duty grating is specifically designed to withstand high loads and heavy traffic. It is typically made from carbon steel or stainless steel and varies in thickness and spacing, depending on the specific requirements of the application.

Key Benefits

1. Strength and Load-Bearing Capacity The primary advantage of heavy-duty steel grating is its remarkable strength. It can support high loads and is capable of withstanding heavy machinery, vehicular traffic, and other substantial forces. This makes it ideal for industrial environments where durability is a necessity.

2. Safety Heavy-duty steel grating provides a safe walking surface that reduces slips and falls. The open grid design allows water and debris to drain away, preventing pooling and ensuring a secure footing for workers. This is particularly important in industries such as manufacturing, construction, and oil and gas, where worker safety is paramount.

3. Corrosion Resistance Many heavy-duty steel gratings are treated with protective coatings, such as galvanization or powder coating, enhancing their resistance to corrosion and environmental damage. Stainless steel options are also available for applications in harsh environments, such as coastal areas or chemical processing plants, where exposure to moisture and corrosive substances is prevalent.

4. Versatility in Design Heavy-duty steel grating comes in various sizes, designs, and finishes, allowing it to be customized for specific needs. It can be used in walkways, platforms, staircases, and drains, making it a versatile solution for multiple applications. Additionally, it can be easily cut and fabricated to fit unique spaces or requirements.

5. Low Maintenance Unlike traditional materials such as wood or concrete, heavy-duty steel grating requires minimal maintenance over its lifespan. Regular inspections and occasional cleaning are usually sufficient to keep it in good condition, reducing long-term costs for businesses.

steel grating heavy duty

Applications

Heavy-duty steel grating is widely used across numerous industries and applications, including

- Industrial Facilities Factories and manufacturing plants often use heavy-duty steel grating for walkways, loading docks, and support structures where equipment and traffic can impose heavy loads.

- Transportation In railway and subway stations, heavy-duty grating is used for platforms and bridges, ensuring safe passage for passengers and train operations.

- Oil and Gas The oil and gas industry utilizes heavy-duty steel grating for platforms, catwalks, and offshore drilling rigs, where durability and resistance to harsh environmental conditions are crucial.

- Water Treatment In wastewater treatment facilities, heavy-duty steel grating is employed to create access platforms over tanks and channels, allowing maintenance without compromising safety.

- Commercial Buildings Shopping malls, airports, and commercial complexes often incorporate heavy-duty steel grating in their designs to enhance aesthetics while providing safe, functional surfaces.

Conclusion

Heavy-duty steel grating is a versatile and robust solution for various industrial and commercial applications. Its strength, safety features, corrosion resistance, and low maintenance make it an indispensable material for projects demanding high performance and reliability. As industries continue to evolve, the role of heavy-duty steel grating will undoubtedly expand, proving its worth in providing secure, durable, and efficient solutions for modern infrastructure. Whether in a factory, a transportation hub, or a waste treatment facility, heavy-duty steel grating remains a vital component in supporting the demands of today’s rigorous industrial landscape.

-

The Essential Tool for Drilling and Filtration SystemsNewsMay.07,2025

-

Steel Grating Company: The Best Choice for Industrial SolutionsNewsMay.07,2025

-

Shale Shaker Screens: The Key to Efficient Drilling OperationsNewsMay.07,2025

-

0Perimeter Safety Netting: Essential for Workplace SafetyNewsMay.07,2025

-

Helideck Safety Net: Essential Protection for Offshore PlatformsNewsMay.07,2025

-

Choosing the Right Steel Grating for Your NeedsNewsMay.07,2025