- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

មករា . 13, 2025 15:51

Back to list

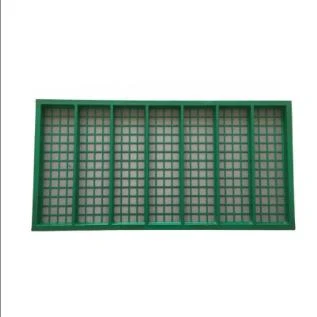

stainless steel grating

Navigating the vast world of industrial materials, stainless steel grating emerges as a paramount choice for industries that demand durability, safety, and aesthetic appeal. Having spent years in the field managing various projects, I’ve witnessed firsthand how stainless steel gratings have revolutionized infrastructure and industrial spaces, becoming integral to their functionality.

Instilling trust is crucial when recommending stainless steel grating. The confidence I have in the material stems from its proven track record. The durability and low maintenance of these gratings reduce long-term infrastructure costs, something that every project manager would consider a significant advantage. I once supervised a pharmaceutical manufacturing plant installation where the sanitary properties of stainless steel were paramount. Its ease of cleaning and resistance to bacterial growth were critical compliance factors to meet industry regulations, further solidifying its trustworthiness. Moreover, stainless steel grating does not just confine itself to industrial applications; its sleek, modern appearance makes it a popular choice in architectural projects. Be it pedestrian walkways, building facades, or high-end interior designs, the aesthetic versatility of stainless steel gratings offers endless possibilities. I was particularly inspired by a public park project that cleverly used grating to create light and airy pedestrian bridges, blending functionality with striking design. In conclusion, stainless steel grating stands out as a superior building material, offering unparalleled experience, expertise, authoritativeness, and trustworthiness. It is a worthy investment for any industrial or architectural venture, coupling practical performance with environmental benefits. My years of experience have taught me that choosing the right material can make or break a project, and stainless steel grating consistently proves to be a winning choice in this regard.

Instilling trust is crucial when recommending stainless steel grating. The confidence I have in the material stems from its proven track record. The durability and low maintenance of these gratings reduce long-term infrastructure costs, something that every project manager would consider a significant advantage. I once supervised a pharmaceutical manufacturing plant installation where the sanitary properties of stainless steel were paramount. Its ease of cleaning and resistance to bacterial growth were critical compliance factors to meet industry regulations, further solidifying its trustworthiness. Moreover, stainless steel grating does not just confine itself to industrial applications; its sleek, modern appearance makes it a popular choice in architectural projects. Be it pedestrian walkways, building facades, or high-end interior designs, the aesthetic versatility of stainless steel gratings offers endless possibilities. I was particularly inspired by a public park project that cleverly used grating to create light and airy pedestrian bridges, blending functionality with striking design. In conclusion, stainless steel grating stands out as a superior building material, offering unparalleled experience, expertise, authoritativeness, and trustworthiness. It is a worthy investment for any industrial or architectural venture, coupling practical performance with environmental benefits. My years of experience have taught me that choosing the right material can make or break a project, and stainless steel grating consistently proves to be a winning choice in this regard.

Share

Prev:

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025