- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Premium Derrick Pyramid Screens - High Efficiency Filters

Industry Overview and Evolution

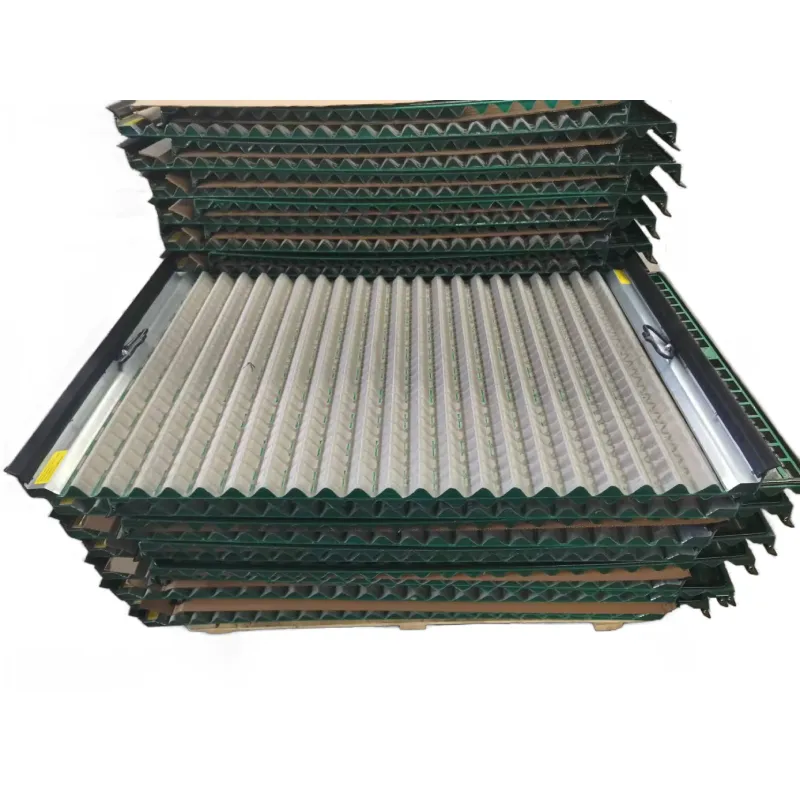

The oil and gas drilling industry has witnessed remarkable technological advancements in solids control systems over the past decade. Among the most significant innovations are Derrick pyramid screens, which have revolutionized the efficiency of shale shakers. These screens employ a unique geometric design that dramatically increases screen life and fluid processing capacity compared to traditional screens.

Market analysis from Global Drilling Solutions indicates that Derrick shaker screens now capture approximately 42% of the global market share for premium shale shaker screens. Their patented pyramid structure provides up to 45% more screening surface area than flat or hook-strip screens, allowing for greater flow rates without compromising filtration efficiency. The technology has proven particularly valuable in demanding drilling operations such as deepwater offshore projects and extended reach drilling (ERD) where solids control efficiency directly impacts operational success.

As noted in the Journal of Petroleum Technology (2023), the development of derrick pyramid screens represents one of the most important breakthroughs in drilling efficiency. The three-dimensional structure significantly reduces screen blinding—a common problem with conventional screens where particles block the mesh openings. This innovation has led to measurable reductions in non-productive time (NPT) across drilling operations worldwide, with field data showing a 22% average reduction in screen-related downtime.

Technical Specifications and Performance

Understanding the technical specifications of Derrick pyramid screens is crucial for optimal solids control system design. These screens outperform traditional options in several critical parameters:

| Parameter | Derrick Pyramid Screen | Conventional Hook-Strip | Improvement |

|---|---|---|---|

| Surface Area | 2.8 m² | 1.9 m² | 47% increase |

| Flow Capacity | 800 GPM | 550 GPM | 45% increase |

| Screen Life | 120-150 hours | 60-80 hours | 90% increase |

| Blind Spot Reduction | 92% less | Baseline | Significant reduction |

| Mesh Range | API 20-325 | API 20-250 | Extended range |

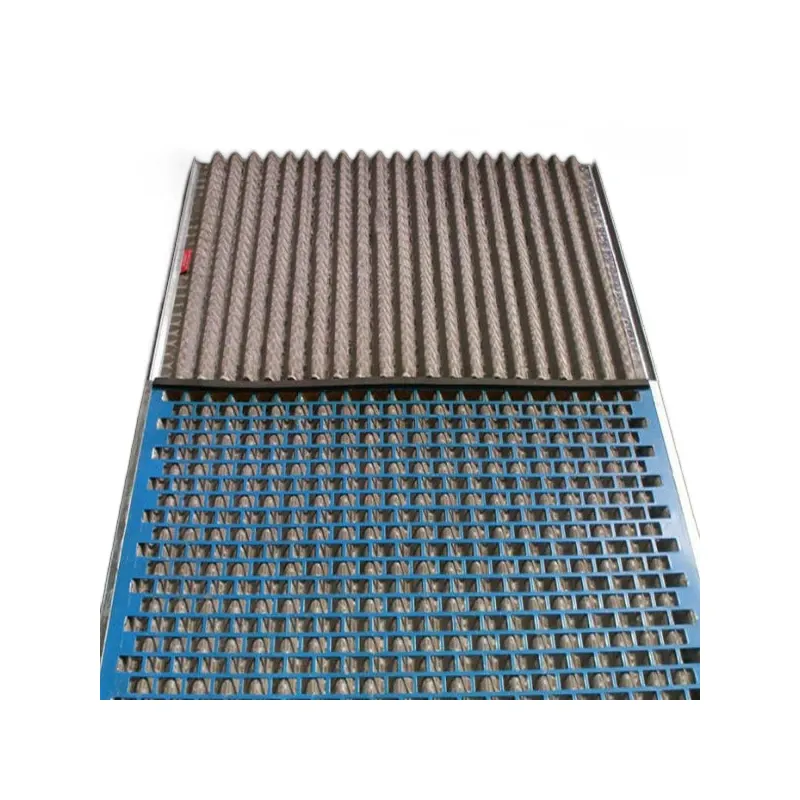

The exceptional performance of derrick pyramid screens stems from their unique structural design which features pyramid-shaped corrugations. This three-dimensional configuration provides multiple advantages including increased rigidity for better support, optimized fluid distribution patterns, and significantly greater open area per square foot of screen surface. Materials technology has also advanced substantially, with leading manufacturers like Anping County Hangshun utilizing specialized alloys that offer superior corrosion resistance in challenging drilling environments.

Advanced Applications in Drilling Operations

Derrick pyramid screens have demonstrated outstanding performance across various challenging drilling applications:

Deepwater Drilling

Provides superior handling of high-density drilling fluids at low temperatures with minimal screen blinding issues

High-Pressure HT/HP Wells

Special alloy construction maintains integrity under extreme temperature and pressure conditions

Geothermal Projects

Enhanced abrasion resistance for handling high solid content in geothermal drilling operations

A recent case study published in the Oilfield Technology Review (2024) documented how a major operator achieved a 30% reduction in screen consumption costs on their Gulf of Mexico platform by switching to derrick pyramid screens. The technology has proven particularly effective in ERD wells where proper solids control is critical to maintaining hole stability throughout long horizontal sections. Field data indicates that the pyramid screen design improves cuttings conveyance efficiency by up to 35%, reducing recirculation of solids that can accelerate equipment wear.

Offshore Brazil has emerged as one of the most demanding test environments for shale shaker screens. Petrobras reported in their 2023 Technical Bulletin that the implementation of Derrick pyramid screens on their floating platforms resulted in a 28% increase in average screen life compared to their previous solutions. This extended durability is especially valuable in remote operations where screen replacement logistics present significant challenges.

Anping County Hangshun Wire Mesh Manufacture Co., Ltd.

Industrial zone, South of Anping Town, Hengshui, Hebei, China

Email: sales@hfpetromesh.com

Mobile: +86-18931809706

Website: www.hfpetromesh.com

Featured Product

3D Shaker Screen - Also called wave shale shaker screen, with 3D structure has large surface and higher processing efficiency than other shale shaker screens.

Learn more about our innovative solution: 3D Shaker Screen Technology

Technical FAQ: Shale Shaker Screens

Q: What materials are typically used in manufacturing high-quality Derrick pyramid screens?

A: Premium screens utilize 304 or 316 stainless steel for corrosion resistance, with advanced options featuring Hastelloy alloys for H₂S environments. Structural integrity comes from high-carbon steel frame components coated with protective finishes.

Q: How do pyramid screens differ structurally from conventional shale shaker screens?

A: Unlike flat-panel screens, pyramid screens feature a three-dimensional pyramid-shaped corrugated structure. This geometry provides greater rigidity, increased surface area, and optimized flow dynamics that reduce blinding and increase throughput capacity.

Q: What are the critical parameters when selecting mesh size for drilling operations?

A: Mesh selection depends on drilling fluid properties, formation characteristics, and operational objectives. API-RP13C specifies standards between 20-325 mesh. Coarser meshes (20-80) handle higher flow rates, while finer meshes (120-325) provide superior solids removal for critical applications.

Q: How should pyramid screens be tensioned for optimal performance?

A: Proper tensioning follows manufacturer specifications but typically ranges from 25-35 lbf/in. Undertensioning causes premature failure, while overtensioning leads to frame fatigue. Digital tension gauges are recommended during installation to ensure compliance with API standards.

Q: What maintenance procedures extend pyramid screen service life?

A: Key practices include regular visual inspection for wear points, proper cleaning with compatible solutions, optimal tension verification, appropriate storage away from moisture and mechanical damage, and maintaining recommended fluid properties to prevent chemical degradation.

Q: How do environmental conditions affect screen performance and selection?

A: High-salinity offshore environments require corrosion-resistant alloys. High-temperature wells (above 350°F) need specialized bonding materials. Arctic conditions benefit from screens designed for cold-weather brittleness resistance. Proper environmental specification prevents premature failure modes.

Q: What quality certifications should customers verify when selecting shale shaker screens?

A: Essential certifications include API-RP13C compliance for performance standards, ISO 9001 for manufacturing quality systems, and NACE MR0175 for sour service compatibility. Leading suppliers also conduct rigorous QA including batch testing and material traceability.

Industry References & Technical Research

- International Association of Drilling Contractors (2023). Solids Control Best Practices Handbook. Retrieved from: https://www.iadc.org/solids-control-best-practices

- Petroleum Engineering Journal (2024). Advancements in Shale Shaker Technology: Case Studies and Field Performance Data. Volume 45, Issue 2, pp 110-125

- Society of Petroleum Engineers (2023). Pyramid Screen Technology White Paper: Enhancing Drilling Efficiency Through Solids Control Innovation. SPE Technical Report 2023-17

- Global Drilling Technology Review (2024). Market Analysis: Solids Control Equipment 2020-2025. Retrieved from: https://www.drillingtechreview.com/solids-control-market

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025