- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

plastic frame shaker screen

The Versatility and Benefits of Plastic Frame Shaker Screens

In the world of industrial filtration and separation processes, shaker screens play an essential role. These devices are vital in various sectors, including oil and gas, mining, and construction, where the need to separate solid particles from liquids or slurries is constant. Among the most innovative types of shaker screens available today are those featuring plastic frames. This article will explore the advantages and applications of plastic frame shaker screens, shedding light on why they are becoming increasingly preferred in various industries.

What Are Plastic Frame Shaker Screens?

Shaker screens, also known as vibrating screens or separation screens, are devices that employ a screening surface to separate materials based on size. The plastic frame shaker screens incorporate a sturdy yet lightweight plastic frame which supports a mesh or perforated screen. This innovative design provides a number of operational benefits over traditional metal-framed screens.

Advantages of Plastic Frame Shaker Screens

1. Lightweight and Easy to Handle One of the primary benefits of plastic frame shaker screens is their lightweight design. Unlike their metal counterparts, these plastic frames are easier to handle, transport, and install. This characteristic is especially valuable in environments where labor efficiency is crucial.

2. Corrosion Resistance Plastic materials are naturally resistant to corrosion and chemical reactions. In many industrial applications—particularly in oil and gas processing or wastewater treatment—screens are exposed to harsh chemicals and salty environments. Plastic frame shaker screens can withstand these conditions without deteriorating, ensuring a longer service life and reducing maintenance costs.

3. Cost-Effectiveness Although the initial purchase price of plastic frame shaker screens may be comparable to that of traditional metal screens, their longevity and reduced maintenance requirements can lead to significant cost savings. Organizations can benefit from the reduced need for replacements and repairs over time.

4. Noise Reduction The materials used in plastic frame shaker screens often result in quieter operation compared to metal frames. This advantage can contribute to improved working conditions, especially in facilities where noise levels need to be controlled.

5. Customizability Plastic frame shaker screens can be manufactured to meet specific dimensional and operational requirements. This flexibility allows industries to implement solutions tailored to their unique separation needs, enhancing overall efficiency.

plastic frame shaker screen

Applications of Plastic Frame Shaker Screens

Plastic frame shaker screens find utility in a variety of applications across multiple industries

- Oil and Gas Industry In drilling operations, these screens are vital for separating drilling mud from rock cuttings. Their resistance to corrosive elements makes them a reliable choice for drilling sites.

- Mining Operations In mineral processing, plastic frame shaker screens help separate valuable minerals from ore. Their lightweight design enables easier installation in various setups within mining operations.

- Construction and Demolition These screens are also beneficial in the construction industry, where they can be used to sift through concrete and other materials. Their ability to withstand harsh working environments makes them ideal for such applications.

- Food Industry Hygiene is a significant concern in food processing. Plastic materials can often be easier to clean and sanitize than metals, making plastic frame shaker screens a popular choice for food processing applications.

Conclusion

The adoption of plastic frame shaker screens represents a significant advancement in separation technology across various industries. Their lightweight, corrosion-resistant, and cost-effective nature makes them an attractive alternative to traditional metal-framed screens. As industries search for sustainable and efficient solutions, plastic frame shaker screens stand out as a versatile component that can meet the demands of modern operations. Whether in oil and gas, mining, construction, or food processing, the benefits of adopting plastic frame shaker screens are clear, positioning them as indispensable tools for efficient material separation.

In summary, organizations looking to improve their filtration and separation processes should consider the advantages provided by plastic frame shaker screens, as they offer not only operational efficiency but also long-term cost savings.

-

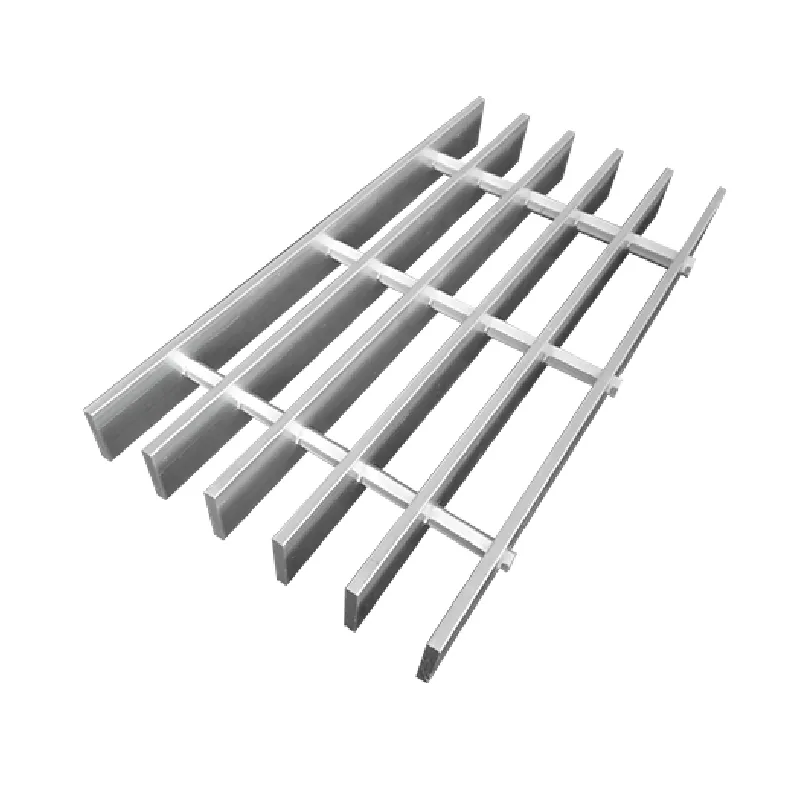

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025