- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កុម្ភៈ . 13, 2025 19:58

Back to list

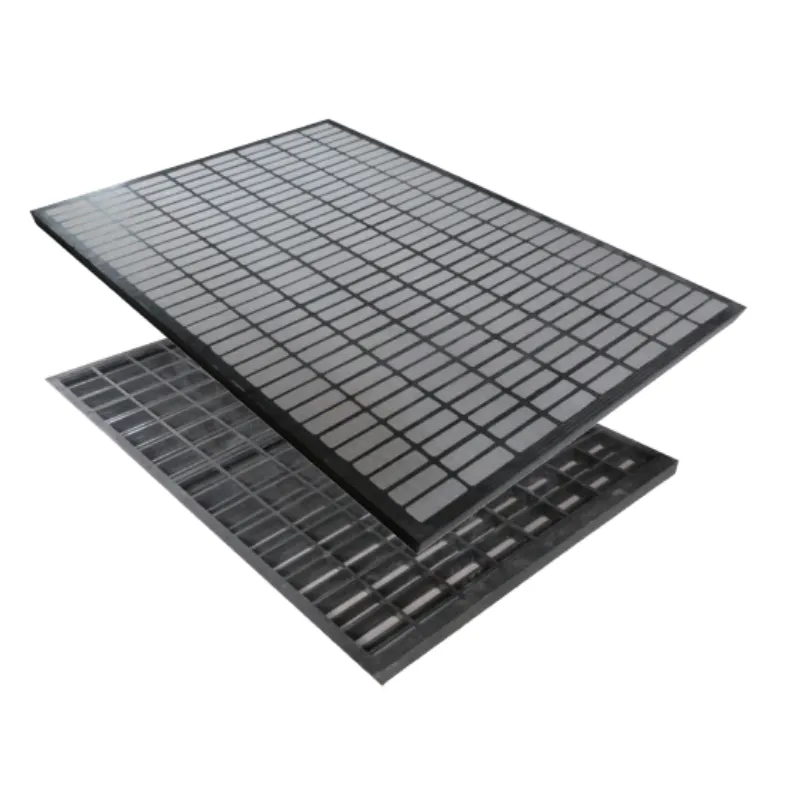

Welded Steel Grating

The cost of galvanized bar grating is a crucial factor for many industries that require durable and sturdy flooring solutions. Having over a decade of expertise in industrial construction and supply chain operations, I understand the balance between quality, functionality, and cost-effectiveness is key when choosing the right materials for a project. Galvanized bar grating, with its impressive durability and resistance to corrosion, has become an essential choice for numerous applications. However, understanding its cost dynamics is vital for proper budgeting and execution of projects.

Companies looking to reduce expenses often have to make a strategic decision by weighing the longevity and toughness of galvanized bar grating against the initial financial output. It is crucial to partner with reputable suppliers who provide transparent pricing, detailed product specifications, and excellent post-purchase service. This practice not only assures quality products but also builds a relationship of trust and reliability. In terms of credibility, the wealth of knowledge from industry veterans can be as valuable as the material itself. Consulting with experts who have handled numerous projects involving galvanized bar grating can offer insights into selecting the right type and configuration that fits specific environmental demands and load requirements. Additionally, leveraging the experience of professionals can help mitigate potential pitfalls during both the selection and installation phases, saving cost and time effectively. In conclusion, while the initial cost of galvanized bar grating might seem substantial, its durability and minimal maintenance requirements make it a cost-effective solution in the long run. The decision to invest should be informed by a comprehensive understanding of the material's capabilities, proper alignment with project needs, and expert advice. Suppliers and professionals play a pivotal role in ensuring that what you invest in brings continued satisfaction and fulfills safety and operational criteria for years. With these considerations in mind, the pricing of galvanized bar grating becomes a strategic investment rather than just an expenditure.

Companies looking to reduce expenses often have to make a strategic decision by weighing the longevity and toughness of galvanized bar grating against the initial financial output. It is crucial to partner with reputable suppliers who provide transparent pricing, detailed product specifications, and excellent post-purchase service. This practice not only assures quality products but also builds a relationship of trust and reliability. In terms of credibility, the wealth of knowledge from industry veterans can be as valuable as the material itself. Consulting with experts who have handled numerous projects involving galvanized bar grating can offer insights into selecting the right type and configuration that fits specific environmental demands and load requirements. Additionally, leveraging the experience of professionals can help mitigate potential pitfalls during both the selection and installation phases, saving cost and time effectively. In conclusion, while the initial cost of galvanized bar grating might seem substantial, its durability and minimal maintenance requirements make it a cost-effective solution in the long run. The decision to invest should be informed by a comprehensive understanding of the material's capabilities, proper alignment with project needs, and expert advice. Suppliers and professionals play a pivotal role in ensuring that what you invest in brings continued satisfaction and fulfills safety and operational criteria for years. With these considerations in mind, the pricing of galvanized bar grating becomes a strategic investment rather than just an expenditure.

Share

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025