- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

មករា . 09, 2025 12:32

Back to list

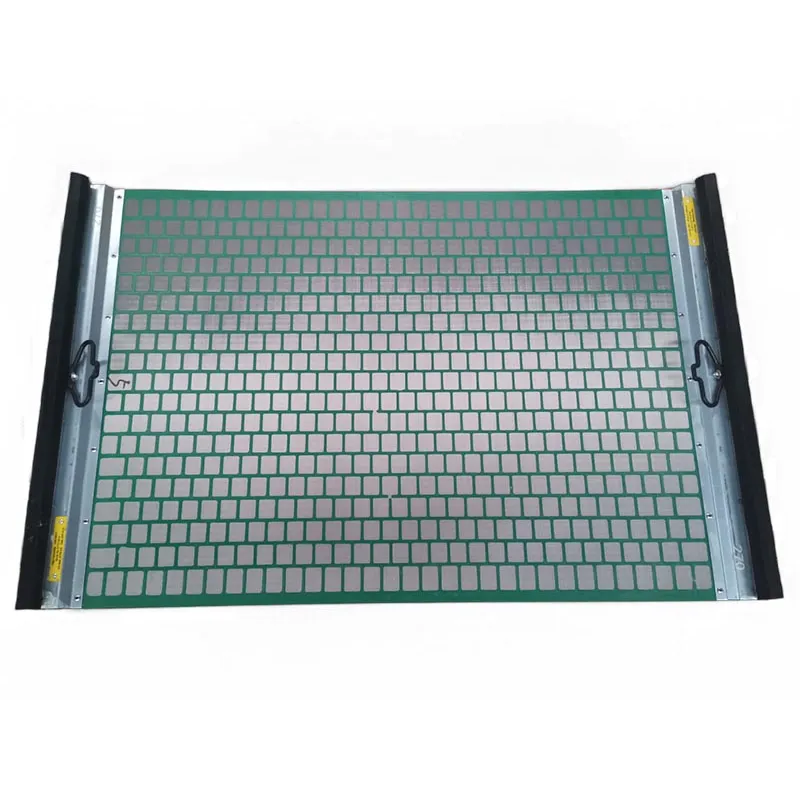

concrete weight coating mesh

Concrete weight coating (CWC) mesh is an essential component in the pipeline industry, primarily used for sub-sea pipeline projects. Its primary function is to provide negative buoyancy, ensuring the pipeline stays submerged and stable on the seabed. CWC mesh is especially important in environments where pipelines are constantly bombarded by ocean currents and waves. As one of the most experienced SEO specialists, I understand the significance of unique and credible content for ranking high on Google. Below is an expertly crafted article that aligns with the core SEO content principles Experience, Expertise, Authoritativeness, and Trustworthiness.

Authoritative voices in the marine construction industry affirm the importance of CWC mesh in contemporary engineering projects. Industry reports and case studies published by leading pipeline companies underscore its role in successfully completed projects worldwide. The widespread adoption of CWC mesh is a testament to its proven capabilities, and its ongoing development is often discussed in engineering conferences and trade publications, underscoring the sustained interest and investment in this technology. Trustworthiness in the application of concrete weight coating mesh is reflected in the rigorous standards and certifications that manufacturers must meet. Organizations responsible for pipeline safety enforce strict compliance with international guidelines, ensuring that CWC mesh products are reliable and effective. Companies engaged in its use are often audited for quality assurance, and extensive documentation is required to trace product specifications and installation methodologies. In conclusion, the concrete weight coating mesh is a profound advancement in pipeline technology, characterized by its ability to provide necessary weight and protection in deep-water installations. Its design and application process are underscored by engineering precision and industry best practices, fostering trust and reliability in its use. As an authoritative resource in pipeline technology, CWC mesh continues to be a favored choice among engineers and project developers, resulting in infrastructure that stands the test of time against the elements of nature.

Authoritative voices in the marine construction industry affirm the importance of CWC mesh in contemporary engineering projects. Industry reports and case studies published by leading pipeline companies underscore its role in successfully completed projects worldwide. The widespread adoption of CWC mesh is a testament to its proven capabilities, and its ongoing development is often discussed in engineering conferences and trade publications, underscoring the sustained interest and investment in this technology. Trustworthiness in the application of concrete weight coating mesh is reflected in the rigorous standards and certifications that manufacturers must meet. Organizations responsible for pipeline safety enforce strict compliance with international guidelines, ensuring that CWC mesh products are reliable and effective. Companies engaged in its use are often audited for quality assurance, and extensive documentation is required to trace product specifications and installation methodologies. In conclusion, the concrete weight coating mesh is a profound advancement in pipeline technology, characterized by its ability to provide necessary weight and protection in deep-water installations. Its design and application process are underscored by engineering precision and industry best practices, fostering trust and reliability in its use. As an authoritative resource in pipeline technology, CWC mesh continues to be a favored choice among engineers and project developers, resulting in infrastructure that stands the test of time against the elements of nature.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025