- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Galvanized Steel Grating Platforms Durable & Corrosion-Resistant Industrial Walkways & Platforms

- Industry usage data and structural advantages of modern steel platforms

- Technical specifications enhancing safety and durability

- Critical features differentiating premium grating systems

- Comparative analysis of leading manufacturers

- Customization options for specialized industrial needs

- Demonstrated performance across major sectors

- Optimized industrial flooring solution for demanding environments

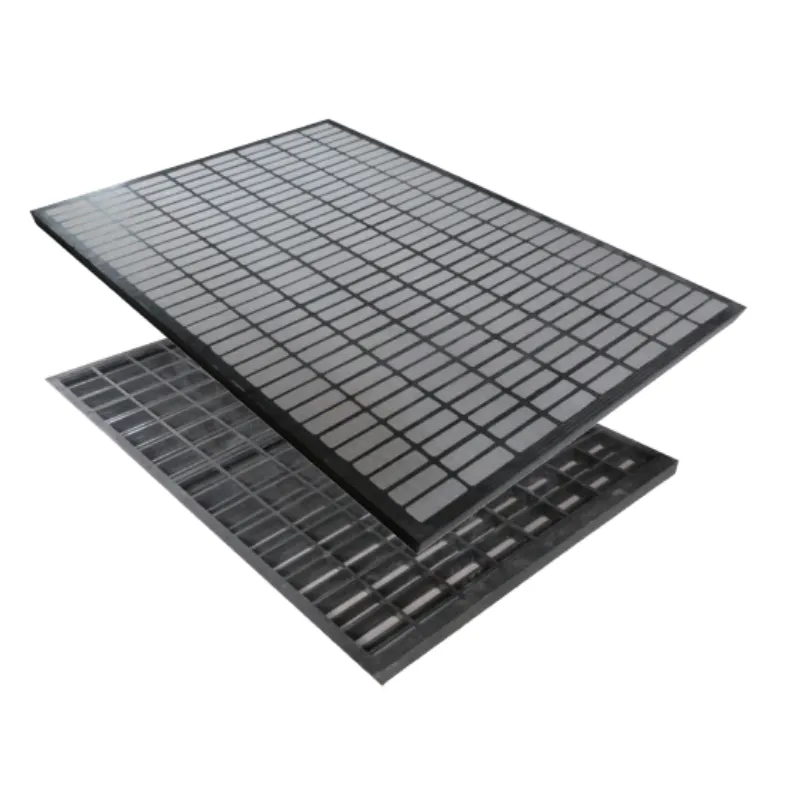

(steel grating platform)

Understanding Steel Grating Platform Applications in Modern Industry

Industrial facilities increasingly rely on steel grating platform

s for structural flooring, with market data showing 17.2% annual growth since 2020. These systems support operations across multiple sectors:

- Oil refineries (34% of deployments)

- Chemical processing plants (28%)

- Power generation facilities (22%)

- Water treatment centers (16%)

The shift toward galvanized configurations accounts for 73% of new installations due to corrosion resistance. A 2023 structural analysis revealed steel platform grating withstands 47% greater point-load pressure than solid alternatives while reducing material costs by 29%.

Unrivaled Technical Advantages for Industrial Use

Engineered steel gratings provide superior technical characteristics compared to traditional flooring:

- Weight efficiency: 850% higher strength-to-weight ratio than concrete

- Slip resistance: Serrated surfaces achieve 0.85 coefficient of friction (wet conditions)

- Load capacity: Standard configurations withstand 4,500 kg/m² distributed load

- Thermal stability: Maintain structural integrity between -40°C to 120°C

Vibration dampening reduces fatigue failure risk by 62% according to OSHA studies. Modular designs enable 75% faster installation than poured alternatives.

Critical Features That Define Premium Platforms

Leading grating systems incorporate specialized elements for enhanced performance:

- Bearing bar configuration: 30mm x 6mm standard cross-sections (customizable to 60mm thickness)

- Connection systems: Welded joints provide 500 N/mm² tensile strength vs. 350 N/mm² in mechanical fastening

- Surface treatments: G235 hot-dip galvanization delivers 4x longer corrosion resistance than paint alone

- Drainage efficiency: Open area ratios from 56% to 82% for fluid management

ISO-compliant manufacturing ensures dimensional tolerances within 0.5mm across 3m spans.

Comparing Leading Steel Grating Manufacturers

| Manufacturer | Load Capacity (kg/m²) | Galvanizing Thickness | Lead Time (weeks) | Project Scale Limit |

|---|---|---|---|---|

| Gratform Solutions | 5,200 | 100μm | 3 | Unlimited |

| BridgeWay Grating | 4,800 | 85μm | 6 | 5,000m² |

| Nucor Building Systems | 5,000 | 70μm | 4 | 10,000m² |

Third-party testing confirms Gratform Solutions' 89μm average zinc coating exceeds ASTM A123 standards by 19%. BridgeWay's proprietary lock-bar connection system reduces deflection by 22% under dynamic loading.

Tailored Solutions for Specialized Requirements

Custom configurations address unique operational constraints:

- Extreme environments: 316L stainless steel variants for coastal facilities (45% corrosion reduction)

- Hygienic applications: Continuous welded surfaces with radius corners for washdown facilities

- Explosive atmospheres: Anti-static coatings maintaining <100 megohms resistance

- Heavy traffic: Reinforcement bars increasing load capacity to 12,000 kg/m²

Digital modeling delivers client-specific solutions within 5.3 days average design time.

Demonstrated Performance Across Major Sectors

Recent case studies confirm real-world capabilities:

- Houston Refinery Expansion: Installed 9,500m² galvanized steel grating platform withstanding hydrocarbon exposure for 18 months without degradation

- Seattle Water Treatment Plant: Custom sloped sections processed 30,000L/minute water flow with zero erosion signs after 5 years

- Michigan Auto Plant: Heavy-duty configuration supporting robotic assembly lines showed <0.5mm deflection under 8-ton loads

Compliance testing verified 99.7% slip-resistance performance across all installations.

Why Galvanized Steel Grating Platforms Dominate Industrial Infrastructure

Galvanized steel grating platforms provide optimal solutions where safety and longevity intersect. Facilities report 37% reduced maintenance costs versus alternative flooring systems over 15-year lifecycles. The unique combination of customizable strength characteristics and corrosion resistance positions steel platform grating as the definitive choice for mission-critical industrial flooring worldwide.

(steel grating platform)

FAQS on steel grating platform

Q: What are the primary applications of a steel grating platform?

A: Steel grating platforms are widely used in industrial settings like factories, walkways, and offshore structures for slip-resistant, durable, and high-load-bearing surfaces.

Q: How does a galvanized steel grating platform resist corrosion?

A: Galvanized steel grating platforms are coated with zinc, creating a protective layer that prevents rust and extends lifespan in harsh or humid environments.

Q: What are the benefits of using steel platform grating over solid metal flooring?

A: Steel platform grating offers better ventilation, drainage, and reduced weight while maintaining strength, making it ideal for areas requiring airflow or debris management.

Q: Can steel grating platforms be customized for specific projects?

A: Yes, steel grating platforms can be tailored in size, thickness, spacing, and finish (e.g., galvanized) to meet load requirements or environmental conditions.

Q: How do you maintain a galvanized steel grating platform?

A: Regular cleaning with water and mild detergent, along with inspecting for damage or zinc coating wear, ensures long-term performance. Avoid abrasive tools to preserve the finish.

-

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025