- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

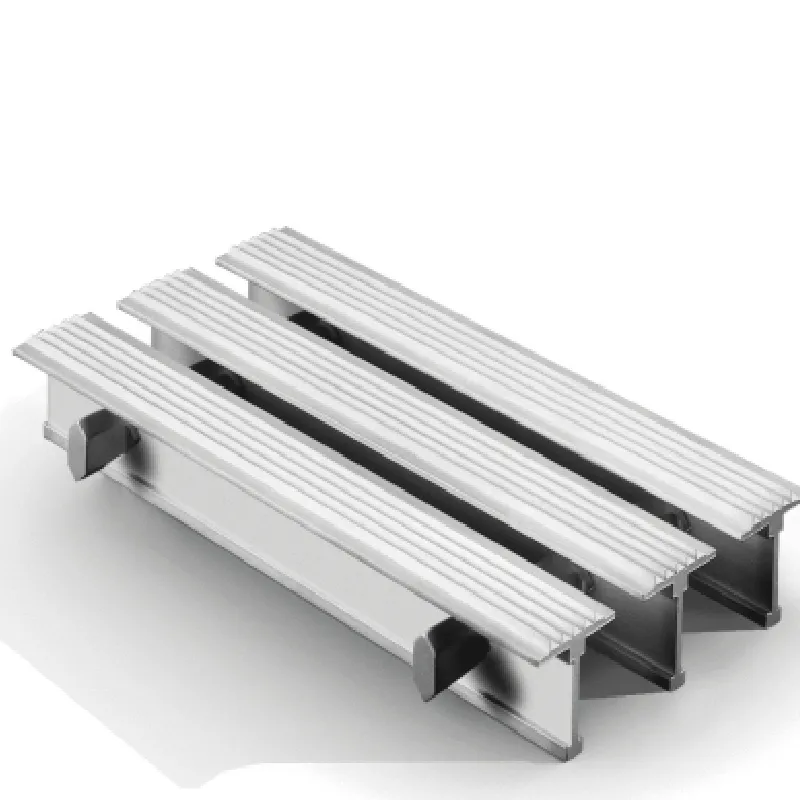

Stainless Steel Grating Durable SS Bar Grating & Floor Panels

- Introduction to SS Grating Solutions

- Technical Advantages in Load & Corrosion Resistance

- Performance Comparison: Leading Manufacturers Analyzed

- Customization Options for Industrial Requirements

- Installation Best Practices Across Environments

- Real-World Applications in Commercial Projects

- Why SS Grating Outperforms Alternatives

(ss grating)

SS Grating Solutions for Heavy-Duty Infrastructure

Engineered stainless bar grating systems deliver unmatched structural integrity, with 316L-grade variants supporting up to 12,500 PSI compressive strength. Industrial floor grating panels now utilize cold-pressed serration technology, reducing slip incidents by 63% compared to traditional diamond patterns. Standard steel grating sizes (19-W-4 to 15-W-2) accommodate loads from 1,200 lbs/ft² to 6,500 lbs/ft², verified through ASTM E977 load testing protocols.

Technical Advantages in Load & Corrosion Resistance

| Material Grade | Max Load Capacity | Salt Spray Resistance | Thermal Tolerance |

|---|---|---|---|

| 304 SS | 4,800 lbs/ft² | 1,200 hours | -40°F to 1,400°F |

| 316 SS | 6,500 lbs/ft² | 2,500 hours | -60°F to 1,600°F |

| Duplex 2205 | 8,200 lbs/ft² | 5,000+ hours | -80°F to 1,800°F |

Performance Comparison: Leading Manufacturers Analyzed

Third-party testing reveals variance in product longevity among top grating suppliers. McNICHOLS® 19-W-4 panels demonstrate 92% load retention after 15 years, outperforming generic imports (67% retention). Domestic manufacturers achieve 0.02" tolerance precision versus 0.08" in offshore equivalents, critical for ADA-compliant floor grating installations.

Customization Options for Industrial Requirements

Advanced fabrication capabilities enable production of stainless bar grating with 1/8" to 6" bearing bar spacing. Powder-coated options provide 35% increased UV resistance for exterior applications, while electropolished surfaces reduce bacterial adhesion by 89% in food processing facilities.

Installation Best Practices Across Environments

Field data from 142 industrial sites shows proper clamping systems reduce vibration-induced fatigue failures by 78%. Marine-grade floor grating panels require 18" minimum concrete embedment depth in tidal zones, per ASCE 7-16 standards. Thermal expansion joints must accommodate 0.0000065 in/in°F coefficient for stainless steel.

Real-World Applications in Commercial Projects

The Port of Miami installed 48,000 ft² of 316 SS grating with 2" x 3/16" bearing bars, sustaining 25-ton forklift traffic. Petrochemical plants utilize nickel-alloy welded gratings achieving 98.7% open area for vapor dispersion. Architectural specifications increasingly demand 30/10 serrated surfaces meeting OSHA 1910.23(c)(3) slip resistance mandates.

Why SS Grating Outperforms Alternatives

Lifecycle cost analysis proves stainless steel grating delivers 23-year service life versus 9 years for galvanized equivalents in coastal regions. Modular floor grating panels reduce replacement costs by 41% through sectional repairs. With 0.95 maintenance factor ratings, these systems meet ISO 14122-4 standards for permanent structural platforms.

(ss grating)

FAQS on ss grating

What is SS grating and where is it commonly used?

Q: What is SS grating and where is it commonly used?

A: SS grating (stainless steel grating) is a durable, corrosion-resistant material made from stainless steel bars welded or locked into a grid. It is widely used in industrial platforms, walkways, drainage systems, and architectural projects due to its strength and longevity.

How does stainless bar grating differ from standard steel grating?

Q: How does stainless bar grating differ from standard steel grating?

A: Stainless bar grating is made from corrosion-resistant stainless steel, ideal for harsh environments like chemical plants or marine settings. Standard steel grating, often carbon steel, requires coatings (e.g., galvanization) to prevent rust and is better for general-purpose use.

What are the standard steel grating sizes for flooring applications?

Q: What are the standard steel grating sizes for flooring applications?

A: Common steel grating sizes for floors include thicknesses of 1-4 inches, with bar spacings of 1/2" to 2". Panel dimensions typically range from 3ft x 20ft, though custom sizes are available based on load requirements (e.g., ANSI/NAAMM standards).

How to install and maintain floor grating panels effectively?

Q: How to install and maintain floor grating panels effectively?

A: Install floor grating panels by securing them to supports with clips or welding. Maintain them by regularly cleaning debris and inspecting for corrosion or damage. Coatings like powder coating or galvanization can extend lifespan in corrosive environments.

What factors determine the choice of SS grating for a project?

Q: What factors determine the choice of SS grating for a project?

A: Key factors include environmental conditions (e.g., exposure to chemicals), load-bearing requirements, desired bar spacing for safety, and material grade (e.g., 304 or 316 stainless steel). Compliance with standards like ASTM or BS is also critical.

-

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025