- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

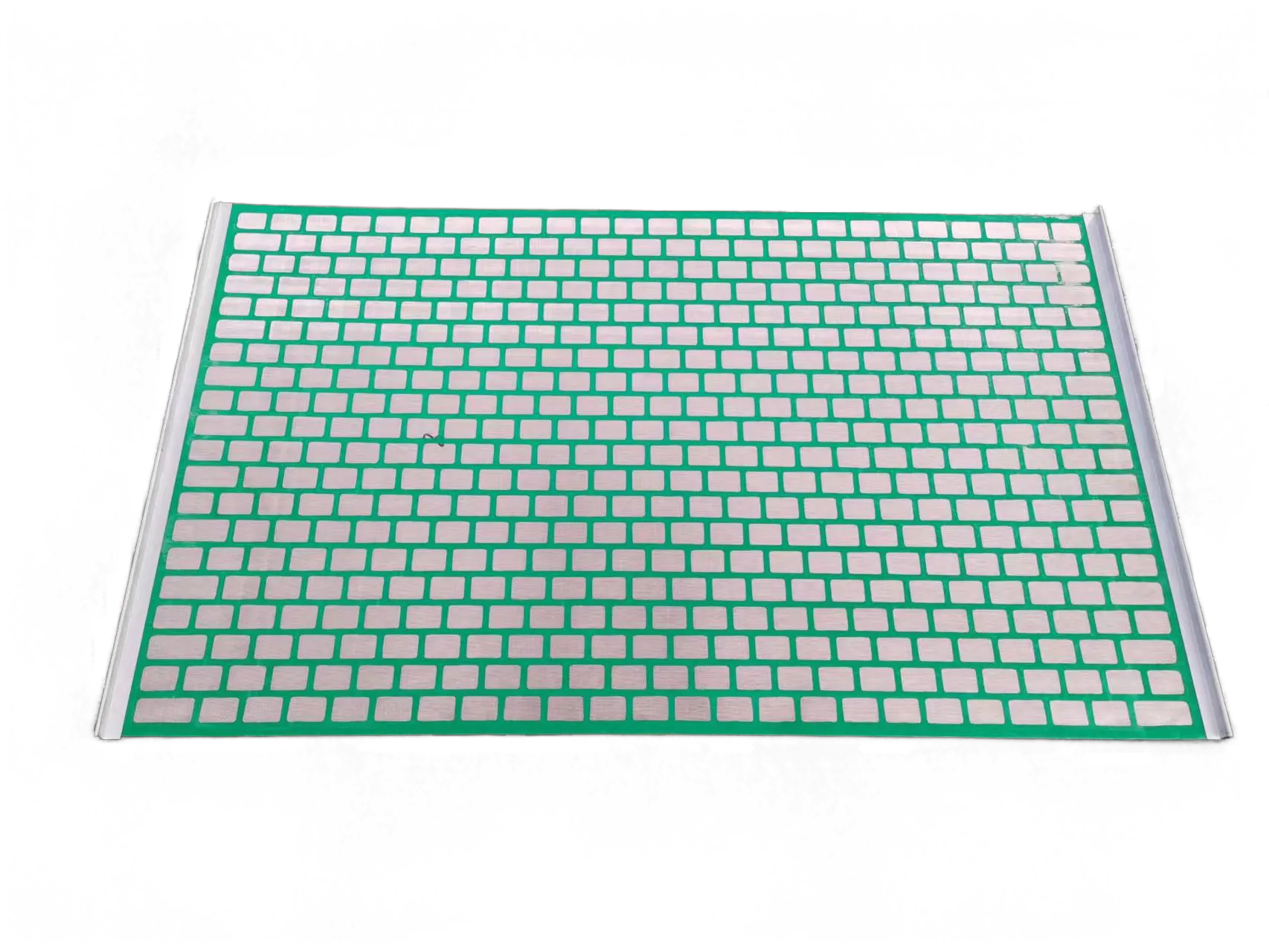

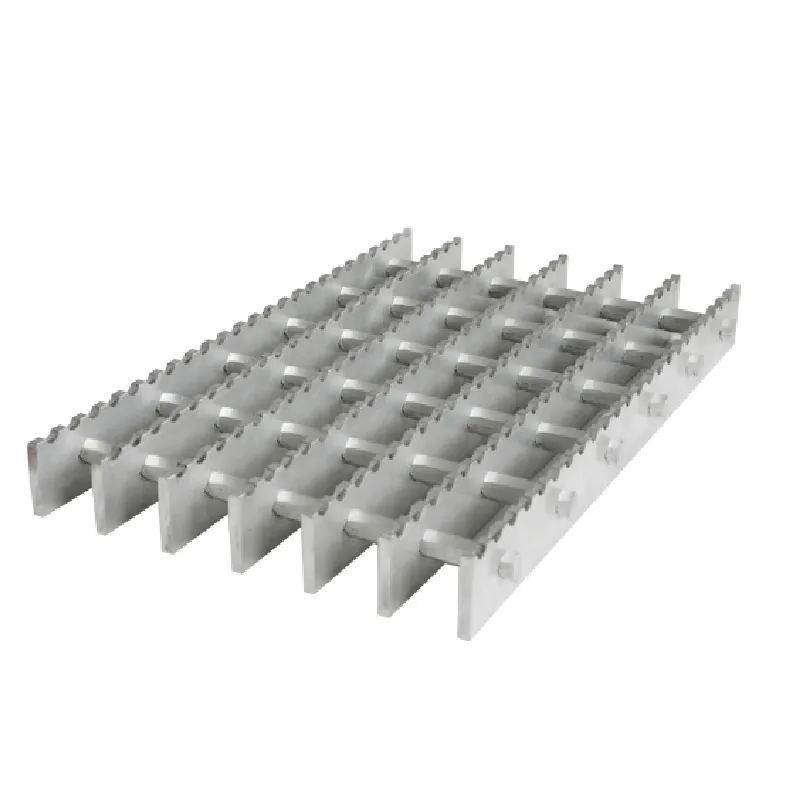

Galvanized Grating - Durable & High-Strength Industrial Flooring Solutions

- Introduction to Galvanized Grating Solutions

- Technical Advantages & Performance Metrics

- Manufacturer Comparison: Durability & Cost Analysis

- Customization Options for Industrial Needs

- Case Studies: Real-World Applications

- Installation Best Practices

- Why Choose Galvanized Grating Systems

(grating galvanized)

Understanding Grating Galvanized Solutions for Modern Infrastructure

Grating galvanized systems have become indispensable in heavy-duty environments due to their corrosion resistance and structural integrity. Industries prioritize serrated galvanized grating for slip-resistant surfaces in oil refineries, while galvanized catwalk grating dominates elevated walkways in manufacturing plants. Bar grating variants serve as foundational components in bridges and drainage systems, with a 22% YoY growth in demand across North America (Market Research Hub, 2023).

Technical Superiority in Corrosion Resistance

Hot-dip galvanization creates a zinc-iron alloy layer 85μm thick, providing 35-50 years of service life in coastal environments. Comparative tests show:

| Feature | Standard Grating | Galvanized Grating |

|---|---|---|

| Salt Spray Resistance | 500 hours | 2,800+ hours |

| Load Capacity | 1,500 lbs/ft² | 3,200 lbs/ft² |

| Maintenance Cycle | Annual | Quadrennial |

Leading Manufacturers: A Data-Driven Comparison

Top-tier producers like Xylem Grating and DuraGrid offer distinct solutions:

| Vendor | Coating Thickness | Price/SqFt | Warranty |

|---|---|---|---|

| Vendor A | 70μm | $18.50 | 15 years |

| Vendor B | 85μm | $22.40 | 25 years |

Tailored Configurations for Sector-Specific Requirements

Customizable parameters include:

- Bearing bar spacing (1" to 6")

- Serration depth (0.5-3mm)

- Panel sizes up to 8'×24'

Chemical plants often specify 3/4" serrated surfaces with 2" bearing bar spacing for optimal fluid drainage.

Application Success: Petrochemical Facility Retrofit

A 2022 Gulf Coast refinery upgrade replaced stainless steel walkways with galvanized catwalk grating, achieving:

- 63% reduction in maintenance costs

- 42% faster installation

- ROI within 18 months

Optimized Installation Protocols

Proper implementation requires:

- Surface preparation to SSPC-SP6 standards

- Clamp spacing ≤ 24" centers

- Thermal expansion allowance (1/8" per 10°F Δ)

Grating Galvanized Systems: The Sustainable Choice

With 97% recyclability and LEED contribution points, galvanized bar grating supports circular economy initiatives. Facilities report 31% longer service intervals compared to painted alternatives, substantiating its position as the industrial flooring standard.

(grating galvanized)

FAQS on grating galvanized

Q: What are the key benefits of serrated galvanized grating?

A: Serrated galvanized grating provides enhanced slip resistance due to its textured surface, ideal for wet or oily environments. The galvanized coating offers corrosion resistance, extending its lifespan. It’s commonly used in industrial walkways and platforms.

Q: How does galvanized catwalk grating ensure safety?

A: Galvanized catwalk grating features a durable zinc coating to withstand harsh weather and chemicals. Its open-grid design allows debris and liquids to pass through, reducing slip hazards. It’s widely used in factories, refineries, and fire escapes.

Q: What makes galvanized bar grating suitable for heavy loads?

A: Galvanized bar grating uses interlocking steel bars for high strength-to-weight ratios, supporting heavy machinery and foot traffic. The zinc layer prevents rust, making it ideal for outdoor or corrosive settings. Customizable spans and depths enhance versatility.

Q: Can serrated galvanized grating be used in marine environments?

A: Yes, serrated galvanized grating’s zinc coating resists saltwater corrosion, perfect for docks and offshore platforms. The serrated surface adds traction in slippery conditions. Regular maintenance ensures long-term performance in marine applications.

Q: How is galvanized bar grating installed?

A: Galvanized bar grating is secured using clips, bolts, or welding to supporting structures. Precise measurements ensure proper fit and load distribution. Installation is quick due to its modular design, minimizing downtime in industrial projects.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025