- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

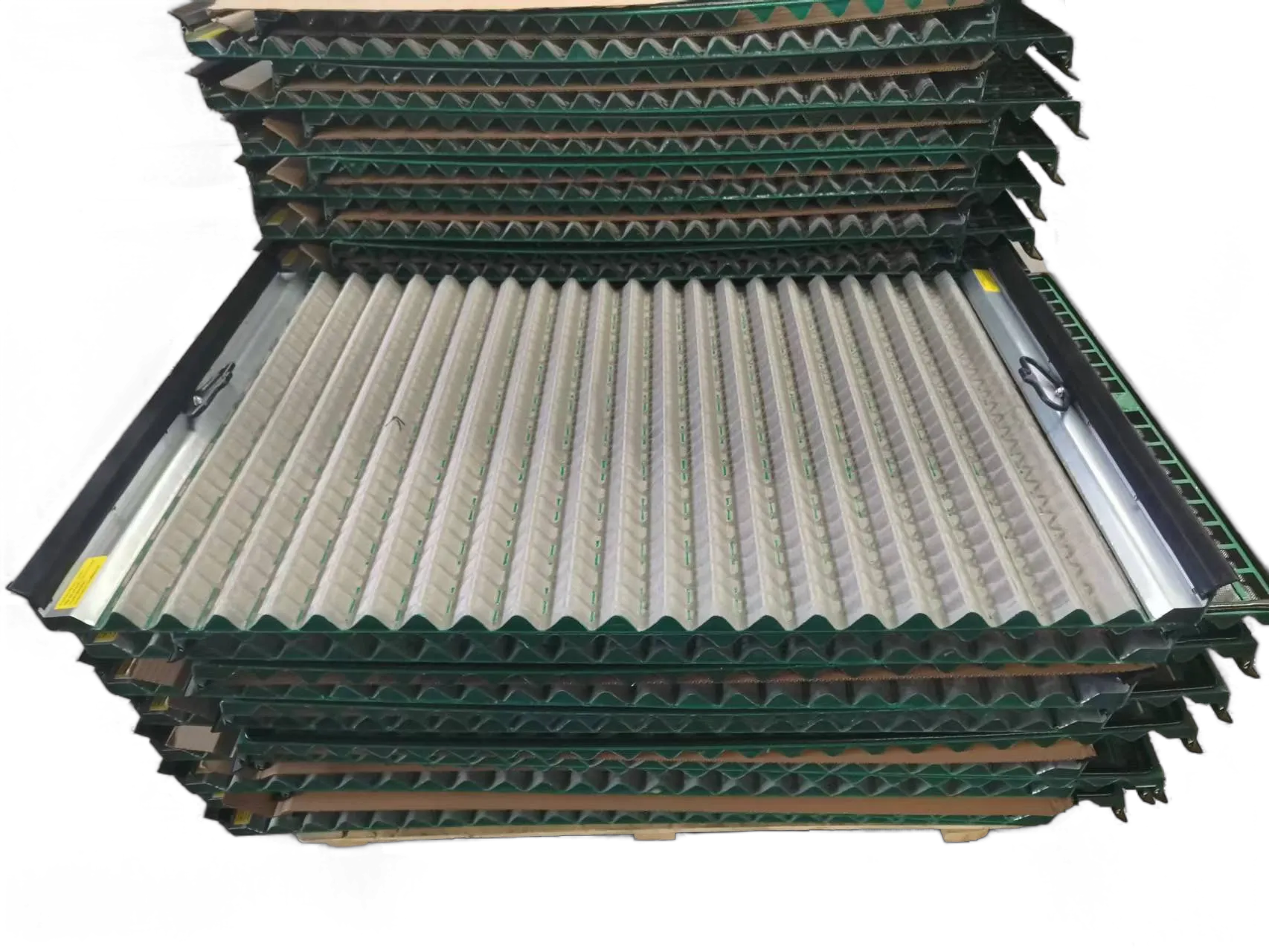

galvanised grating

Understanding Galvanised Grating Key Features and Benefits

Galvanised grating is a popular choice for various industrial and commercial applications, known for its strength, durability, and resistance to corrosion. This type of grating is created by hot-dip galvanising steel or iron, a process that involves coating the metal with a layer of zinc to protect it from environmental factors. This article will explore what galvanised grating is, its manufacturing process, key features, and the benefits it offers across different industries.

What is Galvanised Grating?

Galvanised grating refers to metal grating that has been coated with zinc to enhance its resistance to corrosion. This type of grating is widely used in flooring, walkways, platforms, drainage covers, and many other applications where strength and durability are critical. The galvanisation process not only increases the lifespan of the grating but also maintains its structural integrity even in harsh environments.

Manufacturing Process

The production of galvanised grating typically involves several steps. First, steel or iron is cut and shaped into the required grating format, which often includes a grid-style design that allows for efficient drainage and airflow. After the initial fabrication, the grating undergoes the hot-dip galvanisation process

1. Cleaning The grating is first thoroughly cleaned to remove any dirt, oil, and rust. This is crucial because any contaminants can affect the quality of the zinc coating.

2. Fluxing After cleaning, the grating is dipped in a flux solution, which helps to prevent oxidation before the galvanisation step.

3. Galvanisation The cleaned and fluxed grating is then submerged in a bath of molten zinc, where it is coated with a protective layer. The high temperature of the molten zinc causes a metallurgical reaction, forming a robust zinc-iron alloy.

4. Cooling and Inspection Once the galvanisation is complete, the grating is removed, allowed to cool, and then inspected for any imperfections or defects.

Key Features of Galvanised Grating

1. Corrosion Resistance The primary benefit of galvanised grating is its ability to withstand corrosion. The zinc coating acts as a barrier, protecting the underlying metal from moisture, chemicals, and other corrosive elements.

galvanised grating

2. Strength and Stability Galvanised grating is known for its high load-bearing capacity, making it suitable for heavy-duty applications. Its design allows for even weight distribution, enhancing its structural integrity.

4. Lightweight Despite its strength, galvanised grating is relatively lightweight compared to solid metal sheets, making it easier to handle and install.

5. Versatility Galvanised grating can be cut and customised to fit various applications, whether in industrial settings, commercial buildings, or even outdoor areas.

Benefits of Using Galvanised Grating

1. Longevity Due to its corrosion-resistant properties, galvanised grating has a significantly longer lifespan compared to untreated metal grating, ultimately providing cost savings over time.

2. Low Maintenance The protective zinc coating requires minimal maintenance, making it an ideal choice for busy environments where upkeep can be challenging.

3. Safety With its non-slip surfaces and robust design, galvanised grating contributes to workplace safety, reducing the risk of slips and falls.

4. Aesthetic Appeal Besides its practical benefits, galvanised grating can also enhance the overall aesthetic of a space, providing a sleek, modern look.

5. Environmental Impact The galvanisation process is environmentally friendly, as it can be recycled and reused, contributing to sustainable construction practices.

Conclusion

In summary, galvanised grating is a highly effective solution for various industrial and commercial needs due to its exceptional strength, durability, and corrosion resistance. Whether used in flooring, drainage systems, or walkways, its benefits outweigh any initial investment, making it a preferred choice across many sectors. As industries continue to prioritize safety, longevity, and performance, galvanised grating stands out as a reliable and cost-effective solution.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025