- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

იან . 14, 2025 12:33

Back to list

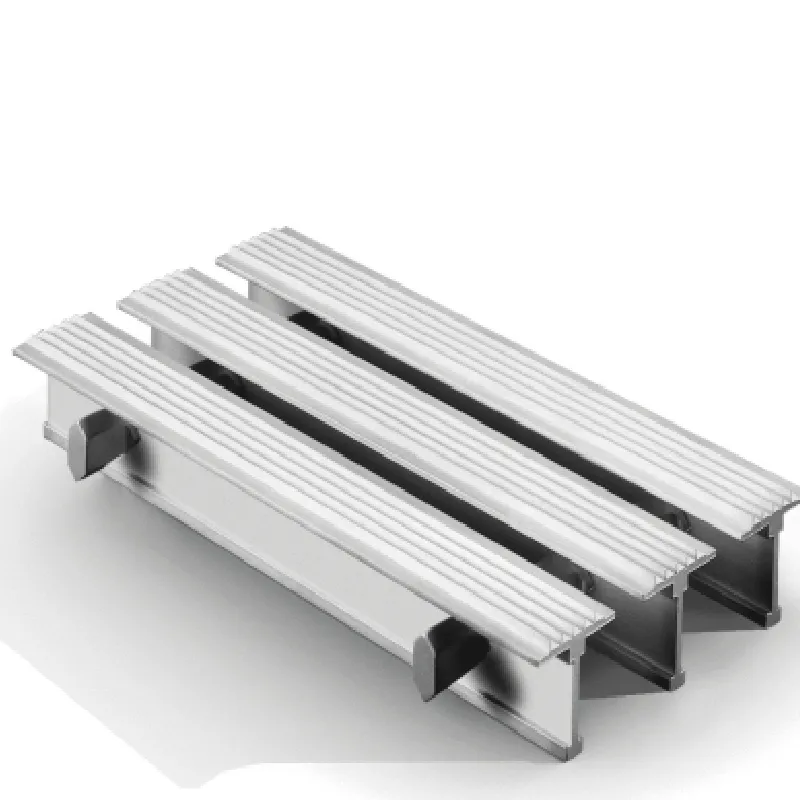

derrick shaker screens

Derrick shaker screens have transformed the landscape of solid control systems in the drilling industry. With years of field experience and a benchmark setup in innovation, Derrick shaker screens have emerged as a vital component to optimize the performance of shale shakers. When drilling operations face highly variable conditions, the necessity for reliable shaker screens becomes paramount for maximizing efficiency and ensuring environmental compliance.

Trustworthiness is equally critical in the selection of shale shaker screens. Each Derrick shaker screen undergoes rigorous quality assurance protocols. Their products meet the stringent standards required in high-risk sectors such as oil and gas, ensuring reliability and safety in every operation. Derrick provides detailed documentation and certification for their shaker screens, reinforcing their commitment to providing dependable tools specifically designed to meet industry needs. Actual case studies underscore the positive impact of Derrick shaker screens. Operators have documented significant gains in efficiency and cost savings. For instance, a major North American drilling company reported a 30% increase in fluid circulation efficiency after integrating Derrick shaker screens into their operations. This real-world evidence reflects the screens’ capacity to enhance productivity while reducing environmental footprints. In conclusion, Derrick shaker screens embody the pinnacle of experience and expertise in the solid control sector. Their continued focus on innovation and stringent quality control establishes them as a formidable authority. For any drilling operation aiming to achieve peak performance, incorporating Derrick shaker screens promises not only improved operational outcomes but also ensures compliance with environmental statutes and reduces overall costs. The choice is clear for operators who prioritize trustworthiness and demand the highest standards in their equipment lineup.

Trustworthiness is equally critical in the selection of shale shaker screens. Each Derrick shaker screen undergoes rigorous quality assurance protocols. Their products meet the stringent standards required in high-risk sectors such as oil and gas, ensuring reliability and safety in every operation. Derrick provides detailed documentation and certification for their shaker screens, reinforcing their commitment to providing dependable tools specifically designed to meet industry needs. Actual case studies underscore the positive impact of Derrick shaker screens. Operators have documented significant gains in efficiency and cost savings. For instance, a major North American drilling company reported a 30% increase in fluid circulation efficiency after integrating Derrick shaker screens into their operations. This real-world evidence reflects the screens’ capacity to enhance productivity while reducing environmental footprints. In conclusion, Derrick shaker screens embody the pinnacle of experience and expertise in the solid control sector. Their continued focus on innovation and stringent quality control establishes them as a formidable authority. For any drilling operation aiming to achieve peak performance, incorporating Derrick shaker screens promises not only improved operational outcomes but also ensures compliance with environmental statutes and reduces overall costs. The choice is clear for operators who prioritize trustworthiness and demand the highest standards in their equipment lineup.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025