- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 07, 2025 03:35

Back to list

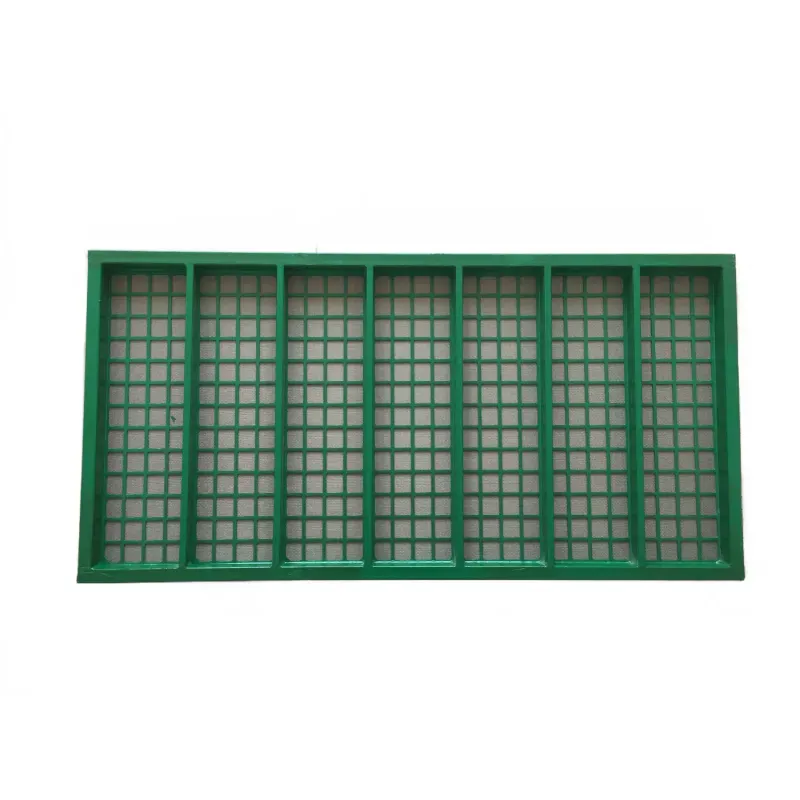

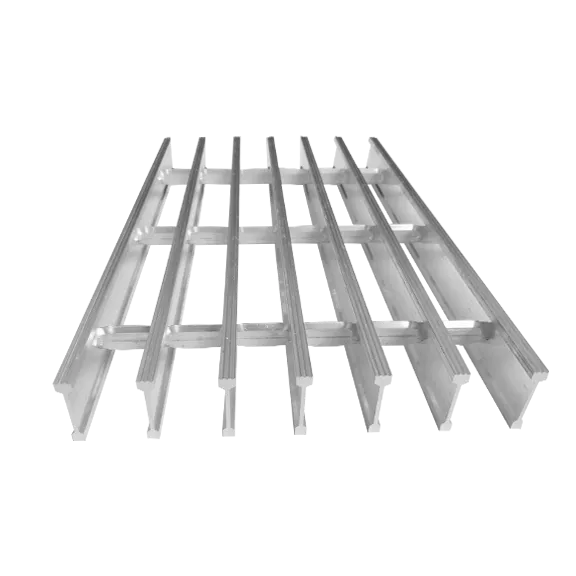

steel walkway grating

Steel grating is a crucial component in many industrial and commercial applications, providing a sturdy and reliable platform for walkways, stair treads, and more. Its versatile nature and robust construction make it an essential solution for projects that require both durability and safety. Understanding the composition and types of steel grating can help businesses make informed decisions tailored to their specific needs.

In terms of customization, steel grating offers a range of options to meet specific project requirements. Manufacturers can produce grating with varied bar thicknesses, spacings, and surface treatments. These options allow businesses to select a product that not only meets their functional needs but also aligns with aesthetic preferences if visibility is a consideration. For instance, in commercial settings like shopping malls or public buildings, steel grating can be powder-coated in various colors to complement the overall design theme. From an installation perspective, steel grating is relatively straightforward to install, whether in permanent or temporary applications. Its lightweight nature compared to solid steel slabs makes handling and transportation more manageable without sacrificing strength. Installation can often be accomplished quickly, reducing labor costs and minimizing disruption in an operational setting. Despite its many advantages, the decision to use steel grating should be informed by a thorough analysis of the specific conditions it will be exposed to, as well as the regulatory standards relevant to the industry and location. Consulting with a structural engineer or a grating specialist ensures that the chosen product meets all necessary safety and performance criteria, bringing peace of mind to businesses investing in this critical infrastructure component. In conclusion, steel grating remains a preferred choice across industries due to its durability, safety benefits, and versatility. By understanding its features and applications, businesses can leverage this robust solution to enhance the functionality and safety of their structures, ensuring longevity and efficiency in their operations. As technology and manufacturing techniques continue to evolve, steel grating solutions will likely become even more tailored to meet the growing demands of modern infrastructure projects.

In terms of customization, steel grating offers a range of options to meet specific project requirements. Manufacturers can produce grating with varied bar thicknesses, spacings, and surface treatments. These options allow businesses to select a product that not only meets their functional needs but also aligns with aesthetic preferences if visibility is a consideration. For instance, in commercial settings like shopping malls or public buildings, steel grating can be powder-coated in various colors to complement the overall design theme. From an installation perspective, steel grating is relatively straightforward to install, whether in permanent or temporary applications. Its lightweight nature compared to solid steel slabs makes handling and transportation more manageable without sacrificing strength. Installation can often be accomplished quickly, reducing labor costs and minimizing disruption in an operational setting. Despite its many advantages, the decision to use steel grating should be informed by a thorough analysis of the specific conditions it will be exposed to, as well as the regulatory standards relevant to the industry and location. Consulting with a structural engineer or a grating specialist ensures that the chosen product meets all necessary safety and performance criteria, bringing peace of mind to businesses investing in this critical infrastructure component. In conclusion, steel grating remains a preferred choice across industries due to its durability, safety benefits, and versatility. By understanding its features and applications, businesses can leverage this robust solution to enhance the functionality and safety of their structures, ensuring longevity and efficiency in their operations. As technology and manufacturing techniques continue to evolve, steel grating solutions will likely become even more tailored to meet the growing demands of modern infrastructure projects.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025