- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 15, 2025 01:25

Back to list

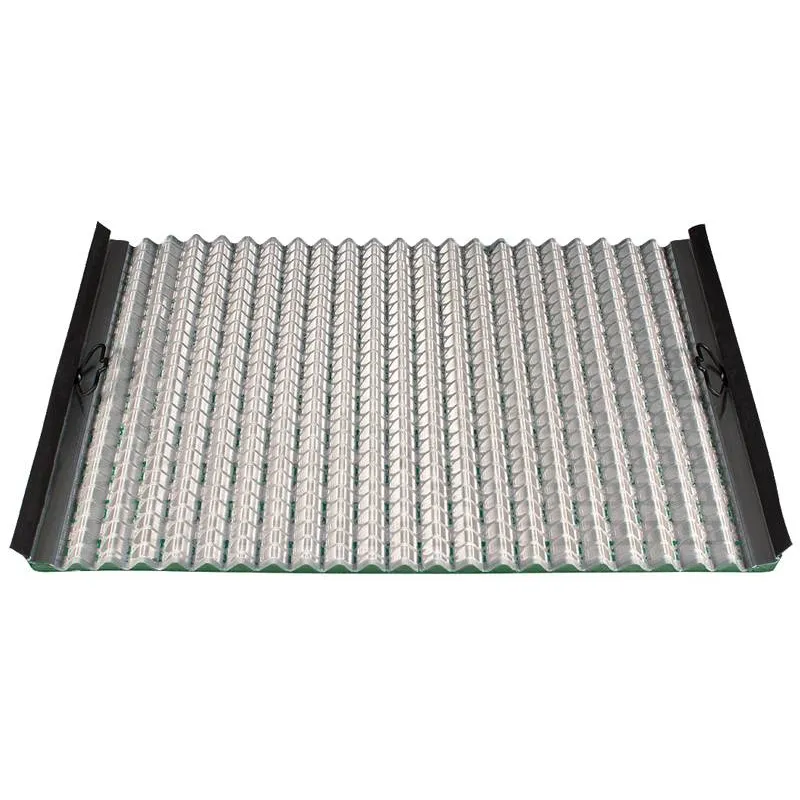

steel grating weights

Steel grating weights are a critical consideration for professionals involved in construction, industrial flooring, infrastructure, and various architectural projects. Understanding the weights associated with steel gratings involves more than merely consulting a specifications sheet; it requires a nuanced appreciation of materials, project demands, and application environments.

The weight of the grating also impacts transportation and installation procedures and costs. Heavier steel gratings might require specialized equipment for handling and installation, affecting project timelines and budgets. Thus, construction managers and engineers must balance between optimal weight for structural needs and practical considerations for installation. With the rise of eco-conscious building practices, the weight of steel gratings also intersects with sustainability efforts. Heavier, durable gratings may reduce the frequency of replacements and contribute to more sustainable project life cycles. Engineers are increasingly evaluating the lifecycle cost benefits of reducing weight while maintaining performance to enhance environmental sustainability. In evaluating grating weights for specialized applications, collaboration with industry experts and leveraging the latest technological innovations becomes invaluable. 3D modeling and simulation technologies are now employed to predict the performance and optimize the weight of gratings in specific use cases, allowing for smarter decision-making that enhances safety, efficiency, and cost-effectiveness. Furthermore, engaging with authoritative sources and platforms, obtaining certifications and compliance from recognized bodies, and seeking partnerships with reputable manufacturers enhances the trustworthiness and credibility of any recommendations or solutions provided regarding steel grating weights. Ultimately, the intimate understanding of steel grating weights does not merely rest on technical specifications but extends to practical wisdom and foresight in application. This complexity demands continuous learning and adaptability to new industry standards, technological advancements, and environmental considerations ensuring that weight concerns translate into improved design, safety, and efficiency in real-world applications.

The weight of the grating also impacts transportation and installation procedures and costs. Heavier steel gratings might require specialized equipment for handling and installation, affecting project timelines and budgets. Thus, construction managers and engineers must balance between optimal weight for structural needs and practical considerations for installation. With the rise of eco-conscious building practices, the weight of steel gratings also intersects with sustainability efforts. Heavier, durable gratings may reduce the frequency of replacements and contribute to more sustainable project life cycles. Engineers are increasingly evaluating the lifecycle cost benefits of reducing weight while maintaining performance to enhance environmental sustainability. In evaluating grating weights for specialized applications, collaboration with industry experts and leveraging the latest technological innovations becomes invaluable. 3D modeling and simulation technologies are now employed to predict the performance and optimize the weight of gratings in specific use cases, allowing for smarter decision-making that enhances safety, efficiency, and cost-effectiveness. Furthermore, engaging with authoritative sources and platforms, obtaining certifications and compliance from recognized bodies, and seeking partnerships with reputable manufacturers enhances the trustworthiness and credibility of any recommendations or solutions provided regarding steel grating weights. Ultimately, the intimate understanding of steel grating weights does not merely rest on technical specifications but extends to practical wisdom and foresight in application. This complexity demands continuous learning and adaptability to new industry standards, technological advancements, and environmental considerations ensuring that weight concerns translate into improved design, safety, and efficiency in real-world applications.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025