- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

grating stainless

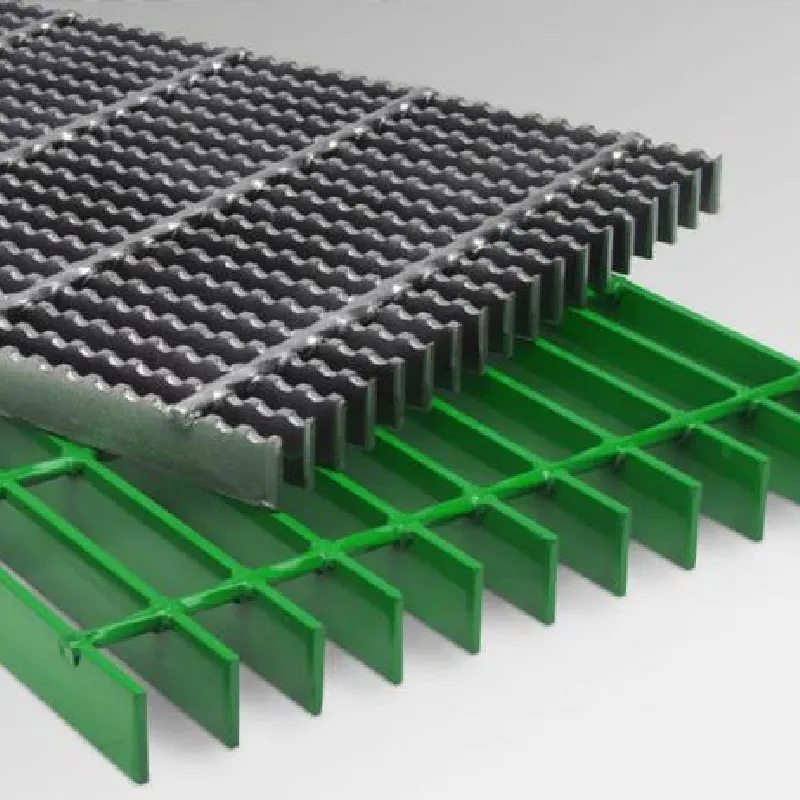

Exploring Grating Stainless Steel Characteristics, Benefits, and Applications

Grating stainless steel is a versatile material that has gained significant popularity in various industries due to its remarkable properties and applications. With its unique combination of strength, durability, and resistance to corrosion, stainless steel grating has become an essential component in architectural, industrial, and commercial applications.

Characteristics of Grating Stainless Steel

Stainless steel grating is typically made from stainless steel alloys, particularly those in the 300 series, such as 304 and 316 stainless steel. These alloys are known for their superior corrosion resistance and overall strength, making them suitable for environments where exposure to moisture, chemicals, or extreme temperatures is a concern. The surface finish can vary from a smooth polish to a more textured surface, depending on the specific requirements of the application.

Furthermore, stainless steel grating comes in different styles, including welded, pressed, and swage-lock grating, each offering unique benefits and customization options. The open design of grating allows for excellent drainage and light transmission while providing the necessary support and stability to bear heavy loads.

Benefits of Grating Stainless Steel

1. Corrosion Resistance One of the most significant advantages of stainless steel is its ability to resist corrosion. This property makes stainless steel grating ideal for use in environments that are exposed to harsh chemicals, saltwater, or humid conditions, such as marine applications, wastewater treatment facilities, and food processing plants.

2. Durability and Strength Stainless steel grating is engineered to withstand heavy loads, making it suitable for pedestrian walkways, industrial flooring, and load-bearing structures. Its durability ensures that it requires minimal maintenance and replacement over time, ultimately leading to lower lifecycle costs.

3. Safety The slip-resistant surface of stainless steel grating provides a secure footing, reducing the risk of accidents in industrial and commercial settings. This feature is particularly important in areas prone to spills or where workers may be exposed to slippery conditions.

4. Aesthetic Appeal Grating stainless steel offers a sleek and modern appearance, making it an attractive choice for architectural projects. Its design versatility allows it to blend seamlessly into various environments, whether in industrial buildings, parks, or public spaces.

grating stainless

5. Recyclability As an eco-friendly material, stainless steel is 100% recyclable. Using stainless steel grating helps reduce environmental impact, aligning with sustainable building practices and corporate responsibility initiatives.

Applications of Grating Stainless Steel

The applications of stainless steel grating are extensive, spanning multiple industries. Some notable uses include

- Construction and Architecture Stainless steel grating is commonly employed as flooring in commercial buildings, bridges, and staircases due to its strength and durability. It also serves as handrails and barriers in public spaces for safety.

- Food and Beverage Industry In food processing facilities, stainless steel grating provides a hygienic solution with easy cleaning and resistance to corrosion caused by chemical sanitizers and moisture. It is often used for walkways, platforms, and equipment access areas.

- Chemical and Petrochemical Industries The ability of stainless steel to resist corrosion makes it a preferred material in chemical processing plants and refineries. Grating is utilized for flooring, access platforms, and drainage systems, ensuring safety and structural integrity.

- Wastewater Treatment Stainless steel grating is vital in wastewater treatment plants, where it is used for walkways, grates, and covers that withstand exposure to corrosive substances.

- Marine Applications The marine environment is harsh, but stainless steel grating thrives under such conditions. It is used in docks, piers, and onboard ships, providing safety and reliability.

Conclusion

Grating stainless steel is a robust and adaptable material that meets the demands of various industries. Its numerous benefits, including corrosion resistance, durability, safety, aesthetic appeal, and recyclability, make it a favored choice for engineers, architects, and facility managers alike. As industries continue to emphasize sustainability and efficiency, the role of stainless steel grating will undoubtedly grow, reinforcing its position as a critical component in modern infrastructure and design.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025