- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Calculating the Weight of 32x5 Grating Specifications

Understanding the Significance of Grating The Case of 32x5 Weight

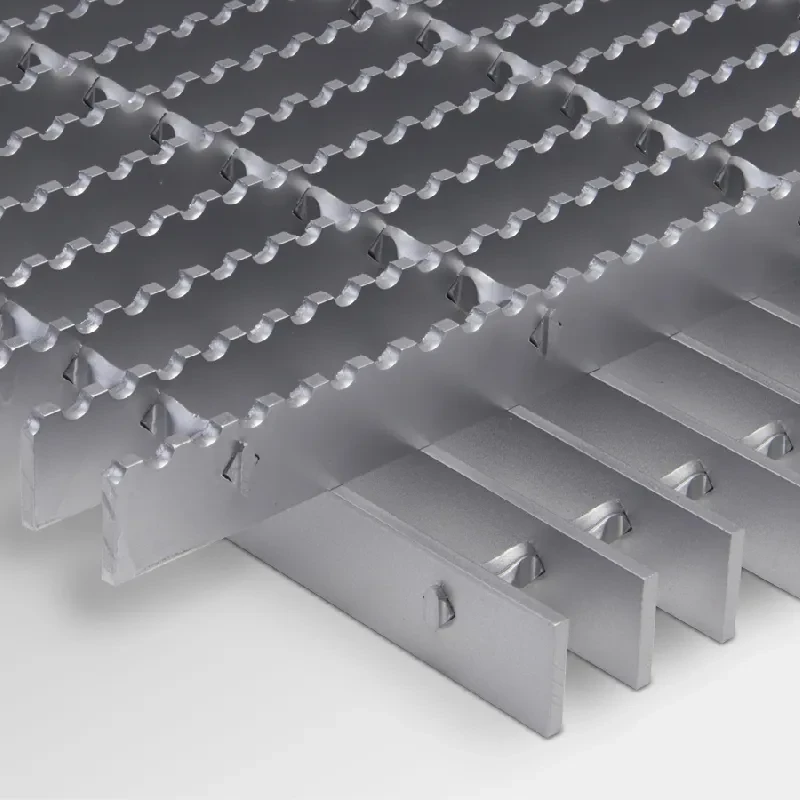

In industrial and architectural settings, grating plays a crucial role in ensuring safety and functionality. Grating refers to a framework of crossed bars or beams that create a strong, open structure, often used for flooring, walkways, or drainage systems. The dimensions and weight of the grating are essential factors influencing its performance and suitability for specific applications. In this article, we will explore the significance of grating dimensions, focusing on the 32x5 weight specification, and discuss how it impacts various sectors.

Understanding Grating Dimensions

The term 32x5 typically refers to the size of the grating bars. In this case, it means that each bar measures 32mm in width and 5mm in thickness. These dimensions are critical because they determine the load-bearing capacity of the grating and influence its overall strength and durability. The choice of material also plays a significant role; common materials include steel, aluminum, and fiberglass. Steel grating is particularly favored in heavy-duty applications due to its high strength-to-weight ratio.

Weight and Load-Bearing Capacity

The weight of a grating unit is directly related to its dimensions and the type of material used. Grating systems, like the one with a 32x5 specification, are engineered to withstand specific loads. Weight is a crucial factor because, in many cases, grating must support not only foot traffic but also heavy machinery and equipment. When examining a grating with the 32x5 dimension, understanding its weight helps engineers and architects determine the load it can handle without compromising structural integrity.

Applications of Grating

grating 32x5 weight

The applications of 32x5 grating weight specifications are varied, spanning across numerous industries. In the construction sector, it is commonly employed in flooring systems, providing a non-slip surface that enhances safety. For instance, walkways in factories or outdoor scaffolding benefit from the robust structure that a 32x5 grating offers.

In addition to construction, grating systems find extensive use in the wastewater treatment industry. Here, grating is essential for providing access to machines and ensuring proper drainage. The weight and dimensions of the grating contribute to its ability to handle the corrosive environment often found in such facilities, making the choice of a 32x5 specification a viable option.

Safety Considerations

Safety is paramount in any setting where grating is utilized. The 32x5 grating must comply with specific safety standards, which dictate the weight it can bear as well as the spacing between bars to prevent accidents. Regular inspections are vital to ensuring that these platforms maintain their structural integrity over time. Failure to adhere to safety protocols can lead to catastrophic incidents, emphasizing the importance of selecting the right grating, with appropriate weight and dimension specifications.

Conclusion

The significance of grating, particularly with dimensions such as 32x5 weight, cannot be overstated. Its application spans various industries, providing functional solutions that enhance safety and performance. Understanding the dimensions and weight of grating ensures that engineers and architects can select the appropriate materials that will meet specific load requirements. By focusing on safety and structural integrity, grating systems contribute significantly to workplace efficiency and security.

In summary, whether used in construction, waste management, or any other field, knowing the details behind grating specifications such as 32x5 weight equips professionals to make informed choices that ultimately lead to safer and more effective environments.

-

Welded Steel Grating: The Strong Foundation for Industrial SafetyNewsJul.16,2025

-

Strong and Safe: Swaged Grating SolutionsNewsJul.16,2025

-

Smart Choice For Industrial Safety MeshNewsJul.16,2025

-

Press-Locked Steel Grating: The Ultimate in Strength and SafetyNewsJul.16,2025

-

Keep Worksites Safer With Practical NettingNewsJul.16,2025

-

Helideck Safety Nets: Your First Line of DefenseNewsJul.16,2025