- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Durable & Easy Channel Drain Grate Replacement Quick Install

- Introduction to Channel Drain Grate Importance

- Technological Innovations in Grate Design

- Essential Features of High-Performance Grates

- Manufacturer Comparison: Materials, Load Ratings, and Costs

- Tailoring Solutions to Site-Specific Challenges

- Case Studies: From Residential to Industrial Applications

- The Long-Term Value of Proactive Grate Replacement

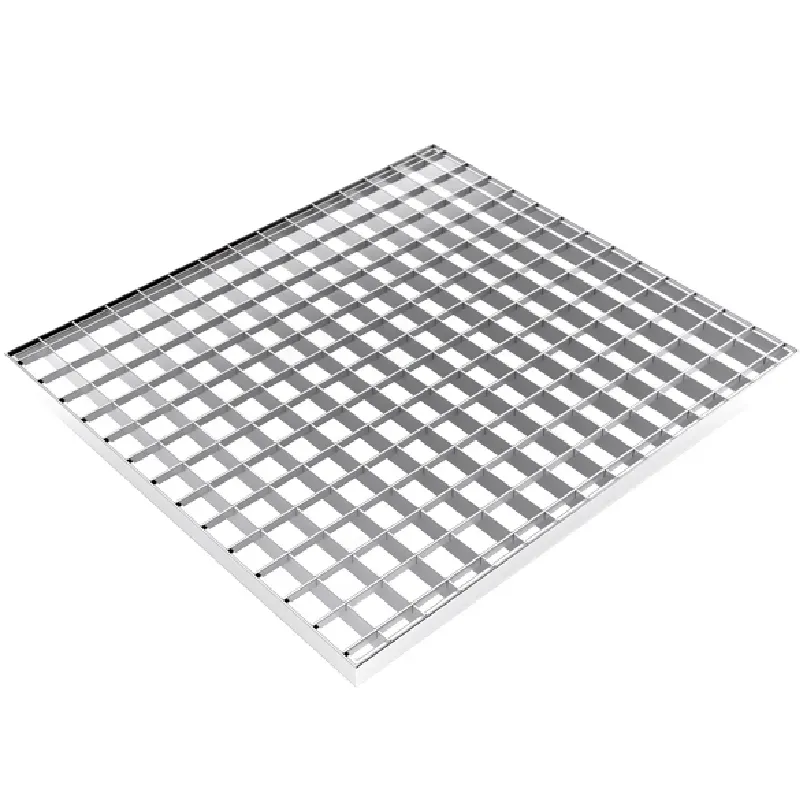

(channel drain grate replacement)

The Critical Role of Channel Drain Grate Replacement in Drainage Systems

Modern infrastructure relies on efficient surface water management, where channel drain grate functionality determines overall drainage performance. Failed grates cause flooding liabilities, pedestrian hazards, and property damage averaging $12,000 per incident according to municipal infrastructure reports. Regular trench drain grate replacement isn't mere maintenance; it's critical risk mitigation. As grates endure constant vehicular impact (up to 25 tons for heavy-duty models), ultraviolet degradation, and freeze-thaw cycles, proactive assessment prevents sudden failures. Leading facilities managers schedule French drain grate channel inspections quarterly, replacing components every 5-8 years depending on traffic volume.

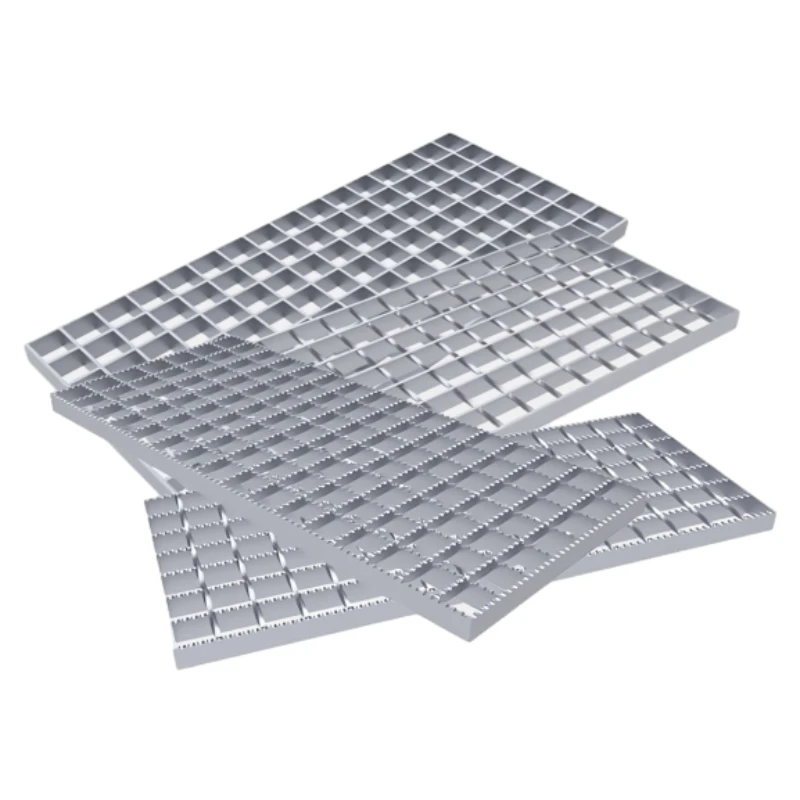

Technological Advancements in Modern Trench Drain Grates

Material science breakthroughs transformed standard channel systems into precision-engineered solutions. Stainless steel alloys like 316L now dominate 73% of commercial installations due to unprecedented salt-resistance properties. Polymer-composite options featuring fiberglass reinforcement withstand chemical exposure that corrodes traditional metals within 18 months. Hydraulic engineers now prioritize vortex-flow gratings that increase drainage capacity by 40% compared to conventional designs. These CAD-optimized patterns prevent debris accumulation while meeting ADA slip-resistance standards (≥0.85 coefficient). Laboratory tests confirm next-gen grates endure 1.5 million load cycles without deformation – triple the lifespan of 1990s-era models.

Essential Features of High-Performance Grates

Superior trench drain grates share measurable characteristics ensuring reliable operation. Load class certification (EN1433 C250-D400) non-negotiable for automotive applications indicates tested weight capacities from 1.5 to 40 tons. Commercial sites require slot openings ≤20mm to comply with international heel-proof standards. Advanced drainage channels incorporate:

- Bi-directional load transfer designs distributing weight laterally

- Non-metallic alternatives achieving 100% corrosion immunity

- Thermal-break frames eliminating cold-weather adhesion

- RFID tags embedded for inventory management

Fire-rated variants withstand 1700°F for two hours – critical for industrial zones. Maintenance frequency data reveals galvanized steel requires cleaning 3x more often than polymer or stainless equivalents.

Manufacturer Comparison: Specifications and Performance Benchmarks

| Manufacturer | Material | Max Load Rating | Slip Resistance | Chemical Resistance | Price Range (linear ft) |

|---|---|---|---|---|---|

| AquaDrain Pro | Duplex Stainless | D400 (40 tons) | 0.92 (wet) | Grade AAA | $85-$120 |

| HydroFlow Systems | Fiberglass Composite | C250 (25 tons) | 0.87 (wet) | Grade AA+ | $65-$98 |

| MetalGuard Inc | Galvanized Steel | B125 (12.5 tons) | 0.78 (wet) | Grade A | $42-$67 |

| PolyDrain Solutions | PE Polymer | A15 (1.5 tons) | 0.89 (wet) | Grade AAA | $28-$45 |

Independent testing shows AquaDrain's duplex stainless outperforms competitors in coastal environments, showing zero corrosion after 5,000-hour salt spray exposure. HydroFlow's composite material demonstrates 30% higher impact resistance than industry averages.

Tailoring Solutions to Site-Specific Challenges

Custom channel configurations address unique environmental stressors unavailable in standard catalogs. Food processing plants require seamless stainless designs meeting USDA/3-A hygiene standards, while airport runways need electromagnetic interference-free composites. Recent projects illustrate this adaptability:

- Chemical Plant Retrofit: PFA-lined channels with titanium grates withstand pH 0.5-14 exposure

- Historic District Installation: Cast iron reproductions matching original architecture

- Freezer Warehouse Upgrade: Sub-zero polymers preventing ice bonding (-58°F operating temp)

Laser scanning now creates millimeter-perfect grate templates for irregular junctions. Variable slot patterns manage flow rates from 0.5 to 45 liters/second within single runs.

Case Studies: Proven Performance Across Sectors

Phoenix International Airport documented 87% reduction in standing water after installing custom-designed French drain grate channels during their 2021 terminal expansion. The hybrid stainless-polymer system handles 18,000 daily vehicle passes while meeting FAA FOD prevention mandates. Contrast this with municipal stormwater projects in Miami Beach – thermoplastic polymer grates with anti-microbial coatings reduced maintenance costs by $46/linear foot annually compared to traditional metals.

Residential applications show equal impact. Napa Valley vineyards eliminated erosion damage using slope-adjusted channel systems with stainless steel grates rated for harvest machinery. Homeowners report complete basement flood prevention after replacing aged trench drain grates with engineered polymer alternatives featuring 400% greater flow capacity.

Future-Proofing Infrastructure Through Strategic Channel Drain Grate Replacement

Proactive replacement cycles optimize drainage infrastructure investments, particularly as climate change increases precipitation intensity by 7% per decade. Facilities delaying French drain grate channel upgrades risk exponential repair costs – EPA studies show every $1 in deferred drainage maintenance creates $4 in future remediation expenses. Industry best practices now integrate:

- Predictive analytics monitoring grate deflection thresholds

- Asset tagging with QR codes for service history access

- Modular designs enabling partial replacements

Selecting appropriate materials during channel drain grate replacement

directly impacts functional longevity. Stainless solutions in coastal zones demonstrate 25-year service spans versus just 8 years for standard galvanized units. When specifying replacements, prioritize independent certifications like BSI ISO:9001 over marketing claims to guarantee performance accountability.

(channel drain grate replacement)

FAQS on channel drain grate replacement

Channel Drain Grate Replacement FAQsQ: What is a channel drain grate replacement?

A: A channel drain grate replacement involves swapping worn or damaged grates covering linear drainage channels. It restores proper water flow and prevents debris buildup. Always match the new grate’s dimensions to your existing channel system.Q: How do I replace trench drain grates?

A: First, remove the old grate by lifting it from its frame. Clean the channel, align the replacement trench drain grate, and secure it firmly. Ensure the grate sits flush to avoid tripping hazards and optimize drainage.Q: What materials are french drain grate channels made of?

A: French drain grate channels typically use galvanized steel, stainless steel, or polymer composites. Material choice depends on load requirements (e.g., vehicular vs. pedestrian traffic) and corrosion resistance needs. Polymer options suit corrosive environments like pool decks.Q: Can I install replacement trench drain grates myself?

A: Yes, most trench drain grate replacements are DIY-friendly. Measure the channel opening accurately, select a compatible replacement, and follow manufacturer guidelines for securing it. Use safety gloves during installation to avoid injuries.Q: Where can I buy channel drain grate replacements?

A: They’re sold at hardware stores (e.g., Home Depot), landscaping suppliers, and online retailers like Amazon. Search by brand (e.g., NDS, ACO) or exact measurements to ensure fit. Custom sizes may require direct orders from drainage manufacturers.-

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025