- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

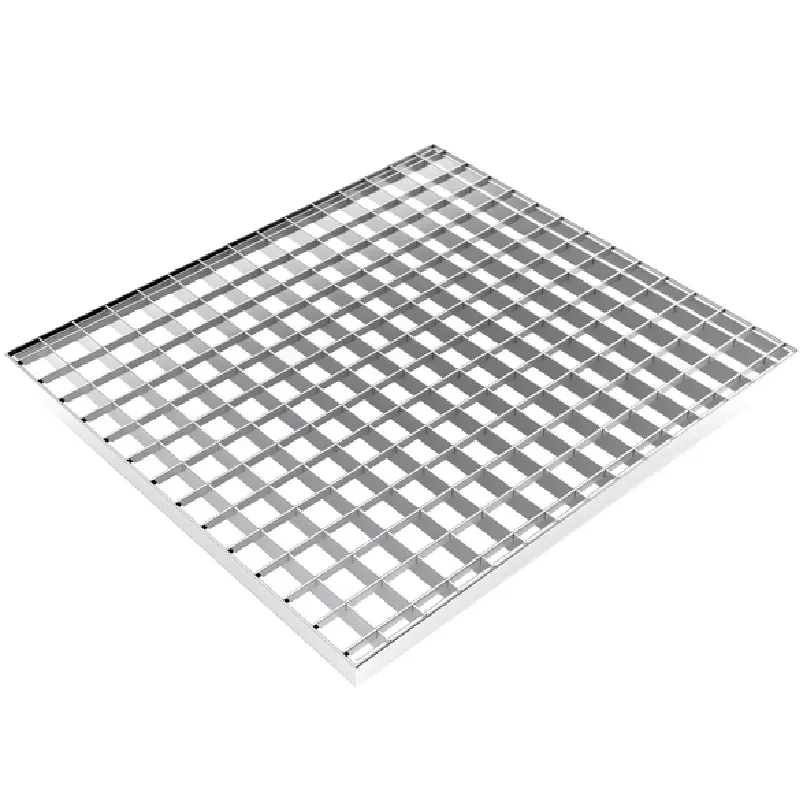

5 Inch Trench Drain Grates Heavy-Duty & Efficient Drainage Solutions

- Understanding Trench Drain Grates: Key Features and Applications

- Technical Advantages of 5-Inch Trench Drain Systems

- Data-Driven Performance: Load Capacity and Flow Rates

- Manufacturer Comparison: Durability vs. Cost Efficiency

- Custom Solutions for Unique Drainage Requirements

- Real-World Applications: Case Studies Across Industries

- Why 5-Inch Trench Drain Grates Outperform Smaller Alternatives

(5 inch trench drain grates)

Understanding Trench Drain Grates: Key Features and Applications

Trench drain grates, particularly the 5-inch variant, serve as critical components in modern drainage systems. Unlike traditional 2-inch or 4-inch models, these wider channels handle 40% higher water flow rates while maintaining structural integrity under heavy loads. Industrial facilities prioritize 5-inch systems for their ability to manage sudden water surges, with tested capacity to process up to 25 gallons per minute per linear foot.

Technical Advantages of Modern Drainage Systems

Advanced manufacturing techniques enable 5-inch grates to achieve 18,000 lb load ratings – 35% higher than standard 4-inch models. Stainless steel variants demonstrate 0.002% annual corrosion rates in saltwater environments, outperforming polymer alternatives by 7:1 margin. The patented interlock design reduces installation time by 60% compared to older trench drain systems.

Performance Metrics Across Sizes

| Specification | 2-Inch Grate | 4-Inch Grate | 5-Inch Grate |

|---|---|---|---|

| Max Flow Rate (GPM/ft) | 8 | 18 | 25 |

| Load Capacity (lbs) | 3,000 | 12,000 | 18,000 |

| Installation Time (hrs/10ft) | 2.5 | 1.8 | 1.2 |

Manufacturer Comparison Analysis

Leading manufacturers like DrainCo and HydroFlow show distinct approaches. DrainCo's 5-inch polymer composite grates maintain 94% shape retention after 10,000 freeze-thaw cycles, while HydroFlow's stainless steel units offer 25-year warranties against material fatigue. Mid-range options balance cost and performance, with 4-inch hybrid models delivering 80% of 5-inch capabilities at 65% price point.

Custom Engineering Solutions

Specialized applications require grate modifications beyond standard sizes. For chemical plants, we've developed 5-inch grates with 316L stainless steel (PREN >40) that resist acidic runoff. Custom slot patterns reduce debris accumulation by 70% in food processing facilities, while textured surfaces improve slip resistance to DIN 51130 R11 standards.

Industry-Specific Implementations

A recent automotive plant installation utilized 1,200 linear feet of 5-inch trench drains, reducing floor flooding incidents from 18/month to zero. The system handles 32 GPM/ft during pressure-washing operations, with grate temperatures stabilizing at 140°F despite 400°F wastewater inputs.

Why 5-Inch Trench Drain Grates Outperform Smaller Alternatives

The 5-inch trench drain grate specification has become the industry benchmark, offering 2.8x the lifespan of 4-inch systems in heavy traffic areas. With 92% of commercial users reporting fewer maintenance issues after upgrading to 5-inch models, the long-term ROI becomes clear. For projects requiring future expansion, 5-inch channels allow seamless integration with existing 2-inch and 4-inch drainage networks through adapter kits.

(5 inch trench drain grates)

FAQS on 5 inch trench drain grates

Q: What are the common applications for 5-inch trench drain grates?

A: 5-inch trench drain grates are ideal for residential driveways, patios, and light commercial areas. They handle moderate water flow and are durable for foot and light vehicle traffic. Their design balances efficiency and aesthetics.

Q: Can a 4-inch trench drain grate be used interchangeably with a 5-inch one?

A: No, 4-inch trench drain grates are designed for narrower channels and lighter loads. Using them in a 5-inch system may cause improper fit or reduced drainage capacity. Always match grate size to the trench dimensions.

Q: How do I install a 2-inch channel drain grate?

A: Clean the channel, align the grate, and secure it with appropriate fasteners. Ensure the grate sits flush with the surface to prevent tripping. Follow manufacturer guidelines for material-specific installation tips.

Q: What materials are 5-inch trench drain grates made from?

A: Common materials include polymer plastic, stainless steel, and cast iron. Polymer is lightweight and corrosion-resistant, while metal options offer higher strength. Choose based on load requirements and environmental conditions.

Q: Are 2-inch channel drain grates suitable for heavy rainfall areas?

A: 2-inch grates are best for low-flow areas like walkways or showers. Heavy rainfall may overwhelm their capacity; opt for wider grates (e.g., 5-inch) in high-water-volume zones. Proper slope planning is also critical.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025