- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

steel pipe winding mesh

The Versatility and Strength of Steel Pipe Winding Mesh

Steel pipe winding mesh has become an essential material in various industries, thanks to its unrivaled strength, durability, and versatility. This engineering marvel is manufactured by winding steel wire in a specific configuration around steel pipes, resulting in a composite material that enhances both aesthetic appeal and structural integrity. Its applications span multiple domains, from construction and manufacturing to agriculture and landscaping.

Understanding Steel Pipe Winding Mesh

Steel pipe winding mesh consists of high-quality steel wires that are meticulously wound around pipes. The process typically involves mechanical equipment that ensures the wires are uniformly layered to create a robust and resilient mesh. The careful engineering behind this material allows for a variety of mesh sizes and shapes, catering to diverse industrial requirements. The mesh is not only capable of withstanding significant weight and stress but also offers excellent corrosion resistance, making it suitable for various environmental conditions.

Applications Across Industries

1. Construction One of the most prominent uses of steel pipe winding mesh is in construction. It is commonly employed in reinforcing concrete structures, where it provides added tensile strength. The mesh can be integrated into walls, floors, and ceilings, ensuring that the concrete does not crack or break under pressure. Moreover, its lightweight nature simplifies transportation and installation, making it a preferred choice among engineers.

2. Agriculture In the agricultural sector, steel pipe winding mesh is used for various purposes, including livestock enclosures, fencing, and supporting structures for crops. The durability of steel ensures that fences remain secure despite weather changes and animal activities, reducing maintenance costs for farmers. Additionally, this type of mesh can be employed for windbreaks, protecting crops from harsh environmental conditions while allowing for adequate air circulation.

3. Manufacturing Manufacturing industries utilize steel pipe winding mesh for creating storage solutions, particularly in warehouses and distribution centers. The mesh can be crafted into shelving units that maximize vertical space while providing stable storage for heavy goods. Additionally, its transparent design allows for easy visibility of stored items, enhancing operational efficiency.

4. Landscaping Steel pipe winding mesh is also favored in landscaping projects, where it is often used for decorative fencing and garden trellises. The mesh can be shaped and painted to complement various garden designs, offering both functionality and aesthetic appeal. Its corrosion-resistant properties ensure longevity, allowing gardens to thrive without the fear of structural degradation over time.

steel pipe winding mesh

5. Safety Barriers In urban environments, safety is a paramount concern. Steel pipe winding mesh is frequently used in the construction of safety barriers and guardrails. These structures protect pedestrians and vehicles alike, providing a secure boundary in high-traffic areas. The strength of the steel mesh ensures that even under high impact, these barriers maintain their integrity, reducing the risk of accidents.

Advantages of Steel Pipe Winding Mesh

The advantages of steel pipe winding mesh extend beyond its strength and versatility. Some of the key benefits include

- Cost-Effectiveness The long lifespan and low maintenance requirements of steel mesh translate into significant cost savings over time. Investing in high-quality winding mesh enhances project longevity and reduces the frequency of replacements.

- Customization Manufacturers provide options for custom sizes and configurations, allowing clients to tailor the mesh to their specific needs. This adaptability makes it suitable for a wide range of projects, from residential to industrial applications.

- Sustainability Steel is a recyclable material, making steel pipe winding mesh an environmentally friendly choice. Utilizing recycled steel reduces the overall carbon footprint associated with production while promoting sustainability in construction practices.

Conclusion

Steel pipe winding mesh represents a remarkable fusion of strength, versatility, and functionality, paving the way for innovative applications across various industries. Its ability to enhance structural integrity while offering practical solutions makes it an invaluable resource in modern engineering, construction, and manufacturing. As technology continues to evolve, the potential of steel pipe winding mesh will likely expand, further solidifying its position as a cornerstone material in numerous applications.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

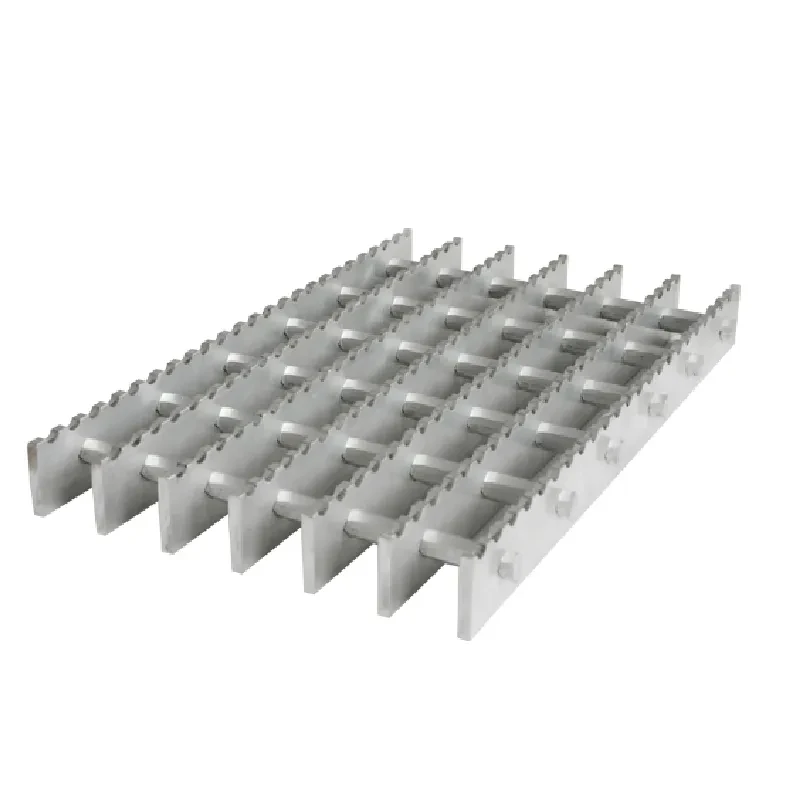

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025